Following this guide You will learn how to cook a powerfull nitrogen laser,

working on athmospheric air as an active medium. The term "powerfull" deserves

a few comments. For a person having been related to nitrogen lasers for some

time even the single millijoule is perceived as damned huge amount of output.

And also the issue of the correct measurements of nitrogen laser output energy

is also dark and cloudy. This is my own point of view, but I dont trust in more

than 50% of published results related to this topic (look further in the

"commentaries" division).

In the process of determining what lasers deserves to be called as "powerfull", one can use the opposite approach - to look from the point of view

of the application. It is well known that most of nitrogen lasers are used

to pump dye lasers. The Internet contains huge amount of homemade designs

of nitrogen lasers. However only a few of them can drive a dye laser to the

threshold. Even fewer ones can do it by the direct (unfocused) beam.

In this guide we'll use the term "powerfull nitrogen laser" in the meaning

that it can drive a cuvette with a proper dye to the lasing threshold by

the direct beam. Its obvious that it won't cut wooden boards or ignite a spark

in the air.

1. RESOURCES

We will need:

- Something flat and hard for the basement of the laser.

(The nitrogen laser teaches to see the other side of the things. The

items, that You earlier considered to be flat, appear to be too curved.

Things, that You earlier considered to be rigid, begin to show

unacceptable bend.)

In my particular case a rectangular sheet of plexiglass (10 mm thick,

300 mm wide and 400 mm long) was taken as the basement. It's a pity but

such resources aren't freely lying on Your road. The thing was bought

in a special shop by a special order.

- Mylar sheet 0.12 mm thick and having enough area to cover the entire

basement of the laser. Even better it is to have some surplus.

The ordinary polyethylene cannot serve as a dielectric for powerfull

nitrogen laser. It has poor electric strength and poor heat strength.

The last will come to use when the laser begins to emit heat in places

of imperfect connection or where the corona discharge glows.

Mylar can be replaced by kapton. However it is much more expensive

and the output will be (according to my experience) generally at the

same level.

After some moment a whine, like "I am a simple student, where me to get

Your fancy mylar?" is not accepted. Any supermarket sells baking sleeves

(aka "oven sleeves", "oven bags", "cooking sleeves", "frying sleeves",

etc, etc...)

The thickness of the mylar foil in the baking sleeve is of course less

than needed. But one can put several layers. Measure the thickness of

the foil available to You and put as many layers as needed to obtain

the total 120 mcm. Usually it will be 6 layers or (if we remember that

the sleeve consists of two layers of film) it will be 3 double layers.

- Kitchen aluminium foil.

Get the most thick among all available. It is rather easy to find one

up to 14 mcm thick. It is thinner than desirable, but further i will

explain the workaround.

- High voltage power supply rated to 16+ kilovolt.

The description of making one almost without applying might and mind

is placed here.

It also appears that he laser may be fed by a common stun gun. The one

should have its sparklength over 16 mm. If You have les powerfull stun

gun, You may use a pair of them in series. How to do that is described

here.

- Some planar steel sheets. Steel scholar rulers are good here. Since the

steel is needed to perform a magnetic attachment, You should check Your

rulers whether they are magnetic.

- Six pcs of small magnets. (The stronger the better.) Ideally use those

fancy neodymium magnets.

- Double gapped spark gap of rail type. (Sometimes they call it rail

switch.) For not to make the description twice, in this guide it wont

be described. Refer here for the procedure of its creation and tuning.

The rail spark gap has sufficiently lower inductance and switching time.

It improves the power of the nitrogen laser reasonably well. If You are

too lazy to make the rail switch, I recommend You to refuse from the

winged design in favour of the charge transfer one (see here in the"commentaries" part)

- The material for the electrodes. For the sake of simplicity I will

write that You will need a pair of aluminium strips 2.5 to 3 mm thick

2 to 3 cm wide and 30 cm long. Further on in this guide You will find

that many other resources will suit. Full range for Your fantasy. The

main requirements are straightness and the sizes allowing to make the

necessary shape.

- A cuvette with a laser dye. The cuvette will be used not only in order

to test the laser's operationability, naturally it is the very instrument

for tuning the laser for maximum power. The cuvette and the dye may be

commercial. On the other hand the cuvette may be homemade (how to make

one You may find here) and the dye solution may be replaced by a juice

of one of lasing markers (the list of markers that have been tested for

lasing You may find here).

Finally one may try to tune the laser for the maximum power using a

photodiode/photoelement as a sensor. However it is less spectacular and

requires more skills.

Some other minor resources required:

- stranded wire

- solder and flux

- alligator clips

- in some cases there may arise a need for a ballast resistor rated to

1..10 MOhm. (The main requirement is that the resistor should endure

the power supply voltage without the flashovers)

Tools:

- scissors

- hacksaw

- drill (with bits and felt disc)

- rough sandpaper (#200..300)

- fine sandpaper (#1000)

- polishing paste capable to work with metal (it may be automotive

polishing compound)

- Filers (fine and rough)

- a caliper (dont expect that a common ruler will suit. You will need to

measure the gaps with 0.1 mm precision)

- screwdriver with a very big dielectric handle. (driving the screws

will be the last thing You will do with this tool. Mostly it will be

usefull for the alignment of the electrodes and for discharging the

laser after its turn-off).

2. PRODUCTION OF THE ELECTRODES

In our design the electrodes should have 300 mm length. (You may choose

longer electrodes, in this case be sure to elongate all other parts of

the laser proportionally).

The working edge of the electrodes has a shape of a knife with steep angle

sharpening.

The picture shows the cross-section of the electrode near the working

edge. The dashed line shows the adjacent electrode.

The statement that the air-filled air-pressure nitrogen laser should have

sharp shaped electrodes for the best performance was found out by at least

three human beings: Alfonso Rodriguez, Jarrod Kinsey and the author of the

present guide. They did it independently and were guided by different

ideas but the conclusion, they came to, was the same.

The angle of electrodes sharpening is determined by two things: the

thickness of the electrodes (the height of the point, where the working

edge is placed, above the dielectric) and the fact that the gap for the

sliding discharge H should be nearly twice as wide as the gap of the main

laser channel h. In its own turn the gap in the main laser channel should

have nearly a half of the value of the gap of the main discharger (rail

switch) that drives the laser to action (for the explanation of this fact

refer to the commentaries section). Since we use double gapped discharger

with the nominal gap from 2x2 mm to 2x3 mm, it means that the main laser

channel width may vary from 2 to 3 mm.

The distance between the electrodes at bottom (along the dielectric

surface) should be choosen twice as wide as the main laser channel H=2h.

This relation is flexible to a certain extent. Just remember that if You

choose too small H, Your laser will be shortened by the sliding discharge

along the surface of the mylar foil. On the other hand if You choose H

too large, the sliding discharge will be too weak to preionize the laser

channel effectively - it will be too hard to obtain a uniform glow between

the electrodes. If we divide this necessary incrementation of the distance

between both of the electrodes, we will get the necessary size of the

chamfering: delta=(H-h)/2=h/2=1..1.5 mm.

The height of the working edge placement above the dielectric (the

thickness of the electrodes) is rather flexible value too. However if it

is too small (~1 mm and less) the discharge will have a tendency to slide

to the dielectric, thus preventing the normal laser operation. In case of

too large height (~5 mm and above) the laser channel appears to be too far

from the preionizing discharge, the preionization efficiency decreases and

the power of laser drops (in the best case... in the worst case You get

inoperational laser). Generally one should better try to place the working

edges of the electrodes at minimal height, where the discharge is still

stable. Practically one may choose the thickness of the electrodes from

2 mm to 3 mm.

Naturally thats all the considerations that determine the sizes and shape

of the electrodes near their working edge. The remaining part of the

electrodes may have arbitrary size and shape with keeping in mind the good

abutment to the wings (wings=metal foil plates) and good mechanical

stability (stiffness). Its obvious that the electrodes alongside should be

as straight as possible. (The light goes along the straight line and there

are no affordable means to bend it in order to follow some curved

electrodes.)

I was able to find the admissible parts in a builders store in a form of

aluminium constructable doorhandles. Their main part has a shape of prism

with a section that resembles a right angular triangle. If we put this

prism onto its cathetus face, its ornate chamfers will form the necessary

acclivity under the sharp edge.

So suitable resource did really reduce the number of processing operations.

But I'm pretty sure that in place You live in, those doorhandles are

unavailable. However there are many other suitable things, just go

shopping keeping a keen eye onto the shelves. If nothing suitable is

obtainable one could take a simple aluminium strip, 2..3 mm thick and

20..30 mm wide and make a necessary bevel. I.e. transform the strip into

a blade with a steep angle of sharpening. Machining here is the best, but

naturally one can do it manually using a filer. On the picture below is

the sample of such an electrode made of aluminium strip.

If the working edge does not want to become sharp - dont worry. Too sharp

edge is too weak to the affect of sparks. And it is almost impossible to

avoid any sparks at least during the tuning procedure. To be a bit

stronger the working edge must have some dulling. Its roundness should

be barely seen by eye, like a dull knife has.

All other sharp shapes (except the working edge) should be rounded by a

filer. It will allow to avoid much of corona during the laser operation.

If the blank is anodized - remove the anodizing by a rough sandpaper.

The working edge should be polished. One can do it using a polishing

paste, drill and felt disc. Naturally the procedure is not as hard as

it seems.

If the working edge for some reason has a curvature or scuffing, it should

be leveled and grinded (sorry my tongue refuses want to say "ground",

since the ground sounds like earth surface to me). Use a sheet of #1000

sandpaper, glue it to a long straight and hard part (a sheet of window glass

or a piece of aluminium angle extrusion and so on) and grind with leveled

motions with even pressing. After the working edge became straight and

flat - just polish it.

The correct electrodes have straight flat shiny working edge with some

dulling (dull knife). If one puts them with their working edges connecting

one to another, and look at some light through them, the maximal clearance

should be not more than a human hair thickness.

NOTICE: though the laser is operational even without the polishing (with

grinded electrodes) dont disregard the polishing stage - it gives a

serious gain in the laser yield (2..4 times).

3. ASSEMBLAGE

The rail spark gap may be attached by bolts or by screw clamps. If You

plan to use bolts, then You first operation will be to drill the holes

for the attachment bolts. Place the discharger to its further position,

mark the suitable positions for the holes and drill them.

Take some sheet of steel foil, or steel rulers and glue it to the area,

where the electrodes will be placed. It will be the baseplate for the

magnetic attachment of the electrodes. At this stage use some elastic

glue (like rubber one). Yes one can use weights or plastic bolts to

press the electrodes, but the magnets are more robust and they work

independently of the gravity force. Ideally the laser may appear to become

portable.

The area covered with steel should cover the whole place of the possible

motion of the electrodes. In our case it is 30x6 cm near the axis of the

laser. It bugs to stumble over the steps under the dielectric. So if You

want to avoid this, it is better to cover all the working area of the

baseplate with steel (as it is shown on the photo). If Your baseplate

is already made of steel, surely You may not bother to add additional

covering.

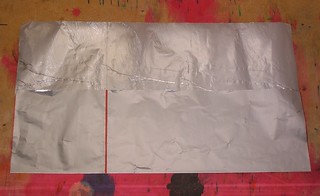

Cut the grounding plate (common conductor) from the aluminium foil. Place

it onto the baseplate and flatten. One may fix it with small pieces of

a thin sticky tape. Otherwise one can leave it as is - it will be pressed

by the discharger, by the electrodes and even by the electrostatic forces,

so it will unlikely be able to move anywhere.

Above the grounding plate put the mylar sheet. Flatten it. The most

thoroughfull flattening is needed if You use a multilayer film (cooking

bags etc.)

Further on one needs to make wings. It's best if You can use rather thick

aluminium leafs. However most of us will use thin (14 mcm) aluminium foil

due to the reasons of availability. Thin foil tends to concentrate field

around its sharp ends. This leads to corona and in turn to dielectric

damage and flashovers. To reduce this harm one should make the wings from

several layers of the foil. The folding method is shown on the photos

below.

The reason of such a twisted folding is to avoid the sharp foil edges

at the perimeter of wings and to place there the folds with noticeable

rounding radii. If You can provide this by other method of folding -

just fold as You like.

The size of the wings is 30 cm x 10 cm. The length is equal to the length

of the electrodes and the width is equal to 10 cm. Decreasing the width

of the wings below 10 cm gives a severe penalty in laser yield. Almost

proportional to the reduced area. Increasing the width over 10 cm causes

slow rise of the output power. In addition it causes increasement of the

stray sparking. Above 15 cm it is really hard to say whether there would

be any increase of power if there were no sparking.

Having put the wings down one should check the capacitance between each

of the wings and the grounding (common) plate. One could use a multimeter

able to capacity measurements. Dependently to the quality of the

assemblage You should get from 3 nF to 5 nF (per each wing). If the

capacity is too large You probably use too thin dielectric (it should be

0.12..0.15 mm thick) If the capacity is too low - it most probably

signs that there is too much of inflatness and bubbles there.

Here is the photo of the wings having been put inplace.

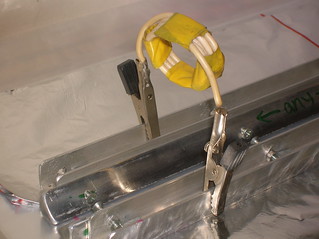

Before putting the electrodes it has sense to make some contact spring

stiffners. They are intended to provide good contact between wings and

electrodes along all the length of the electrodes. In practice the

electrodes will never abut to the baseplate since they are straight

and the baseplate is not perfect. Irregularities and bubbleses will make

things even worse. And the contact in the nitrogen laser must be not

"just good" but "perfect". When the laser fires there flow kiloamperes

of current and every excessive milliohm affects the laser yield.

The spring contact stiffners may be made using the same aluminium foil, folded

several times and corrugated. The length of the stiffners should be equal

to the length of the electrodes and the width should be 10..20 mm

Put the stiffners over the internal edges of the wings (along the edge,

where the electrodes will sit). Above that install the electrodes. Press

them down. The pressure force should be enough to shear the stiffners.

Fix the electrodes by magnets.

Install the rail spark gap. In places where its leads lie onto the foil

its also desirable to use stiffners in order to enhance contact.

If You use multilayer mylar, it has sense to put some plastic (dielectric)

plate (2..3 mm thick) just below the discharger between mylar layers. It

may be a cut of school ruler or something else. This technique will

reduce the flashovers under the discharger, where the presence of ground

plate tends to stimulate them.

It remains only to make an electric contact between wings for the constant

currents. A small coil of 3..4 turns of strand wire suits well. The leads

of the coil may be soldered to alligator clamps and it helps to attach and

detach the coil without ruining other things.

Low number of turns in the coil helps to suppress the stray sparking.

However it isnt the panacea.

After installing the coil to its place the laser is ready.

4. TUNING

Tuning of the laser consists of two stages:

- tuning of the rail type spark gap (the rail switch)

- tuning of the laser itself

In order to tune the rail spark gap, take the fresh-assembled laser, set

the laser electrodes to be parallel to each other and set 2..3 mm spacing

between them. Then tune the rail spark gap. Its tuning procedure has already

been described in the spark gaps guide . Its main sense is to obtain more or

less even sparking along the spark gap by means of changing the pitch of the

central electrode. If the spark shines only in a single place, Your rail

spark gap has almost no advantages against a common pinpoint type one.

Usually one can get 2-3 sparks simultainiously in one (first) of the gaps and

3-5 sparks in the another (second) gap without too much of torture. This

gives a serious reduction of the inductance and increasement of speed.

By very thoroughfull tuning after many iterations one can get even better

results. However its a bit excessive for this type of laser.

Having tuned the spark gap one can advance to the laser tuning stage.

For the correct tuning one should keep in mind the next three things:

- Laser has a preferencive direction of light. If it was assembled

accurately (with no bubbles under the dielectric, with evenly lying

wings and with evenly pressed electrodes) the preferencive direction

is towards the spark gap side. The reason for this phenomenon is due to

the dissipation of the electric energy (i dont like the word 'wave' in

this context) when it travels from the spark gap to the far away end

of the laser electrodes. The amplitude of pulse drops and You are forced

to make the spacing narrower there. And it immediately causes the laser

to 'push' the light towards the side of wider spacing. i.e. towards the

spark gap. The longer laser is, the more prominent this phenomenon becomes.

Of course one can align the electrodes to have more narrow spacing near

the spark gap and more wide at its far away end, thereby forcing the laser

to emit in the opposite direction. However it leads to the situation, when

the strong pulse is applied where the spacing is narrow end and the weak

field pulse is applied where the spacing is wide. At the narrow place this

causes sparking and arcing and at the wide place there's almost no discharge.

It means less overall power than in case of the laser having been aligned

properly.

- If the laser electrodes are not parallel to each other, they form some

wedge (see the picture below). The light does always prefer to go towards

the side where the spacing is wider (size h2 at the picture) rather than

towards the narrower side (size h1 at the picture).

It is due to the fact that the time it takes the electric discharge to cover

the wider spacing is always more than the covering time for the more narrow

one. It causes the discharge to form a kind of "travelling wave". And of

course if the light goes into the same direction as the travelling wave does,

it experiences more amplification in the freshly pumped medium. In addition

to this there exists a kind of trumped phenomenon. I.e. the light travelling

in the diverging waveguide tends to be pushed out towards the bigger end.

And the reflective metal electrodes do the job nicely. The wedge directs

the light so strongly that it allows to force the laser to emit into the

direction opposite to the preferenced one. The existence of the preferenced

direction can hereby be noticed only if one compares the top achievable

powers for the cases of aligning the electrodes for one direction and for

the another.

- There exists an optimal average value of the inter electrode spacing

h=(h1+h2)/2, at which the output power is at maximum. As it was mentioned

above, in the first approximation the optimal value of h is equal to the

half of the value of the gap in the main (driving) spark gap. However it

is only approximation. The precise value of the h is to be found in the

process of tuning.

Thus the tuning of the laser is the process of searching for optimal

spacing between the laser electrodes and the optimal angle between them.

Here we have a two parametric optimization problem.

A single parametric optimization problem is simple. A two parametric

optimization problem is disgusting. And the three parametric optimization

problem is the one, u should avoid if possible.

So this disgusting problem have to be solved during the laser tuning.

Namely due to its disgustness, I doubt that anyone wants to solve it

too often, so: dont forget to write down the resulting values of h1 and h2!

In future this writing will come in handy many times.

If You literally followed the guide and the important sizes of the laser

(gaps in the spark gap, sizes of wings and electrodes) are just the same

as here, the h1=2.5 mm and h2=2.7 mm would be a good initial approximation.

In order to set the spacings it is handy to use drill bits. Take two of them

having 2.5 mm diameter. Wrap the shank of one of them with a sticky tape or

thin paper until it diameter reaches 2.7 mm. Use a caliper to measure the

resulting diameter. In other case You can use a 2.7 mm drill bit if it is

available to You.

Insert the shank of the 2.5 mm drill bit between the laser electrodes

somewhere closer to the end far from the spark gap. Insert the 2.7 mm bit

between the electrodes somewhere near the end being closest to the spark gap.

Press the electrodes one towards another until they clamp the drill bits.

Then extract the drillbits carefully.

Having turned on the laser, most probably You immediately will observe a

purple glow between the electrodes (maybe with some stray sparkies). There

will also be a bright spot if a fluorescent paper was put on the way of the

beam near one of the laser ends. If there is no glow between the electrodes

it means that something has gone completely wrong and it is needed to open

the laser and research for the reasons. If the glow is present but there's no

lasing, first of all look for the beam at the other end of the laser. Then

try to change the average spacing between the electrodes (usually towards

reduction). If there's still no lasing, check the straightness of the

working edges of the electrodes. Also check the quality of the electric

connection between the electrodes and the wings. (However bad connection

usually affects the glow - it can be seen in the form of dark or dimmed

places).

After having obtained the lasing, start to tune the thing towards the top

power. Now You will need a cuvette with laser dye. Take a commercial one

or glue it Yourselves. Fill it with a laser dye solution to somewhere 2/3

of its volume. The solution concentration should be suitable for nitrogen

laser pumping. One should take rhodamines or coumarines in 3..7 mmol/l

concentration. Maybe it is not wise to use fluorescein here. It is capricious

in power and concentration. If You have no experience with the dye lasers

it may be more wise to get a certainly working solution. E.g. TextileWhite

bleacher or a juice of yellow-green highlighter (a list of working ones You

may find here and here). If You want to make the cuvette by Yourself, keep in mind

that the glue seam shouldn't block the beam path of the dye lasing (see the

figure below)

NOTICE: non lasant light sources normally do not emit the radiation with a

prominent pattern (directivity). On the contrary in order to obtain a

directed beam they use some concave mirror, lenses, apertures and so on.

The simple fluorescence is not lasing, so its light will produce a more or

less even exposure of the screen (sheet of paper) being placed aside near

the cuvette. If You observe a stripe of light there's a high probability

that it gives the evidence of lasing. (And the more sharp this stripe is

the higher that probability.) If You observe a prominent spot - the

conclusion is obvious.

Set the cuvette with the dye solution on the way of the nitrogen laser beam

as close to the electrodes as possible. If the nitrogen laser was assembled

correctly, the cuvette is good and the dye solution is suitable (see above)

then You should see a light spot on a paper placed aside of the cuvette. If no,

try to adjust the inter-electrode spacing. Dont shy to check the dielectric

layer for the bubbles, check the electric connection between the wings and

the electrodes, check the correctness of rail spark gap settings (the gaps

in there should be not less than 2 mm, and there should be several sparks

in parallel when it fires.)

Then arm Yourself with a screwdriver having a huge dielectric handle. Hit the

electrodes gently to adjust the angle between them. As the output power

grows up, increase the distance between the dye cuvette and the end of the

laser. If You missed the optimal angle (and unless You got some experience

You will miss it oftenly), interrupt the procedure, turn off the laser,

discharge it, and then take the drill bits and renew the setting of the

spacings. Then start to align the electrodes again.

SAFETY WARNING. If You are making a laser following this guide, You seem to be rather experienced person in lasers and high voltage stuff. It is kinda awkward to remind such a person that one may touch the electrodes only when the laser is switched off and all its capacities are discharged.

The laser, if having been correctly assembled and tuned, provides lasing of

good dyes in rectangular cuvettes at a distance of 40..50 cm without any lenses

or focusing. (The real laser grade high purity dyes have low threshold and

can be driven at 100..120 cm.) With aged or burned electrodes this value can

drop to 25..35 cm. If You cannot achieve 40 cm during tuning (and You are

sure that You have a proper dye solution). I recommend check the electrodes

and repolish the working edges of them if needed (especially since they could

be fried seriously after some failures in the tuning process).

If for some reason You can not achieve lasing of dyes in the direct beam

(maybe the proper dye was not available, or some other problem) You still

can tune the laser using the cuvette with dye. Use a lense here (Better -

cylindrical one.) As the cylindrical lens one can use some glass tubing filled

with water or even a piece of round glass rod (in the last case one should

check if the glass of the rod transmits enough light at the nitrogen laser

wavelength. If You are using a lens, then the measure of the output power

would be the maximal displacement of the cuvette from the lense's focus

rather than the maximal distance from it to the laser's electrodes. Tune

the laser using the lens until the maximal shift from the focus (when the

dye's lasing is still present) becomes comparable with the focal length of

the lens. Then You should be able to use the direct beam.

There's no limit to the perfection. And it is understandable that as Your

laser becomes more powerfull, You want even more. However it is better to

stop at some point. When You think that the results of tuning are good enough,

carefully measure the spacing between the electrodes at the front and back

ends of the laser. One can try to use a caliper, but it is better to use

the drill bits again. Wrap their shanks with a thin tape until they fit

closely the gap between the working edges of the electrodes. Then measure

the obtained diameters and write them down.

5. OPERATION

Despite its simplicity the laser appears to be a serious device that will

be of the very use for You further on. As to myself, it helped me to discover

a plurality of laser dyes among common and readily available materials, it

helped to choose the substance for a protective UV filter etc etc...

If You have a powerfull power supply, the laser should be operational at

least up to 100 Hz (the limiting repetition rate for the uncontrolled air

filled spark gap without forcefull blow). However I didn't check it at the

repetition rates higher than 30 Hz. Because it's scary. First of all - the

noise. The next is that the heating becomes very prominent at higher

repetition rates. And the last is the lifetime.

Concerning the noise - I urgently recommend You to take the measures for

its suppression. The most simple thing You can do - is to cover the laser

channel with a dielectric plate. If You feel ready to design a more serious

covering dont forget to cover it with rubber from inside (or with another

sound absorbing material).

Concerning the lifetime - get used to keep a peaceful mind each time as

the dielectric under the wings fails. Try to convince Yourself that the mylar

is an expendable material. Just replace it, set the electrodes again, and

continue the work as if nothing had happened. Remember that the laser works

near the limit of the mylar's dielectric strength. In order to provide a

practically eternal life to it, it would take to reduce the voltage more than

by two times, and this will turn the laser into a useless toy.

Even SwissRocketman (known by his amazing videos on YouTube) reports a mean

lifetime of the dielectric in his lasers at the order of 10000 pulses. And he

is a professional, not amateur. By the way try to divide 10000 pulses by 30 Hz.

It appears that the laser has a resource of only 5 minutes of flawless

operation. And with 1 Hz repetition rate it gives about 3 hours.

Dont forget to discharge the laser's wings after You've finished Your work.

Not only it will preserve You from a spontaneous electric shock, but also will

prolong the time before the next replacement of the dielectric. When the mylar

stays under the voltage it expends its lifetime in vain.

Aluminium electrodes have limited lifetime too. They tend to become fried.

So every 2-nd or 3-rd replacement of the dielectric should be accompanied

with the renewing of electrodes' working edges. Arm Yourself with a drill

equipped with a felt disc and polish the working edges carefully. After

several repolishing procedures it may be needed to flatten the working edges

by some grinding tool. Alfonso Rodriguez reports that the maximal lifetime

one can obtain with electrodes made of "inox". As far as I could know the

inox is a kind of stainless steel. Moreover it seems to be a very specific

kind. It is because the steels, especially stainless ones, are the compounds

with a high specific resistance. And in accordance with this fact all my

attempts to make a nitrogen laser with steel electrodes lead to fail. Its

curious, but the discharge looks much better with steel electrodes. It is

more uniform and has less sparks (or even free of them). But the laser output

with the steel electrodes appears to be miserable. Judging of that the INOX

appears to be able to register both of the useful properties: it is strong to corrosion

and it has good conductivity. Other high conductive materials: bronze and

copper will work not worse than aluminium does. However they also have similar

corrosive strength, that means they will require cleaning as frequently as

aluminium.

After the long storage the electrodes are also recommended to get some

polishing. It will free You of the barren search of the places "where the

power has gone to".

About the drawbacks

The laser has rather high spread of the output energy from pulse to pulse.

The order of this spread is up to 50% (thanks goodness it works without

omissions). First of all it is due to the instability of the firing voltage

of the (uncontrolled) spark gap, and in the next turn it is due to the

discharge instabilities in the laser channel filled by air (oxygen

contaminated nitrogen). Using the triggered spark gap and filling the laser

with pure nitrogen one can eliminate these instabilities, but the design

complexity will be the price. On the other hand one may notice that even

with such a high spread from pulse to pulse the average power (averaged over

10..100 pulses) is very stable.

The replacement of the mylar (with the related necessity to remove the

electrodes) arises pain in the pass if the laser have been aligned to an

optical scheme. However one should just think beforehand about this. Choose

one of the electrodes to be a reference one (the one that sets the direction).

Trhow an additional alignment ray along it. And after the reassemblage the

reference electrode can readily be set along the alignment ray, and the other

electrode can be easily aligned to the reference one. It should be mentioned

that if You already have the sticks of the necessary diameters (e.g. drill

bits that You've used on a stage of the alignment of the laser), You will

only need to set the necessary spacing at the front end of the laser and

at its back end. No additional alignment or adjustment will be needed.

By the way the laser is a powerfull electromagnetic pulse generator. I've

never seen a cell phone killed by this small atmospheric nitrogen laser, but

a few transport/credit cards with RFID chip it did fry. It usually happens

like this: You forget the card in the breast pocket, then You come close to

align the electrodes, and the next day it appears that the card is dead. So

the expensive electronic devices should not be placed closer than several

meters from the working laser. However it happens rather rarely. Some devices

had a long life close to the nitrogen laser and still alive.

6. Comments

* The Shape of the Electrodes

The fact that sharp electrodes give more power may be described by the

next three factors:

- field concentration

- increasement of the preionization

- decreasement of the operational volume with correspondent increasement

of the gain.

Let's begin from the end of the list.

How can the value of the gain affect the value of the output power?

Two cases are possible here:

- saturated gain, when the amplificated

beam just gathers the energy stored in the volume of the gas

- unsaturated gain, when the beam is weak enough to gather a sufficient

part of the stored energy, so the amplification is limited to the gas

gain ability.

In case of the saturated gain it's obvious that the output energy is

proportional to the volume, it is being gathered from, multiplied by

the energy density. And this product does not depend to the sharpness

of the electrodes. Narrower edges - the volume decreases but the density

increases. Wider edged - the density decreases but the volume increases.

When the energy deposition per unit of length of the electrodes is given,

its output energy is proportional to the length of the laser diminished

by some small starting part.

In case of the unsaturated gain the output energy grows exponentially

with the length of the laser. Each centimeter of the excited gas

amplifies the light by several times.

However practically we don't observe thousand times growth of the output

with every surplus ten centimeters of length. On the contrary the

linear growth looks more trustworthy. I.e. we deal with a saturated gain

and the concentration of the energy deposition can affect only the

length of that 'starting' part - the length of that part of the laser,

where the light becomes amplified to the intensity that it begins

to gather the sufficient part of the stored energy. This length is

rather short (3..7 cm) when compared to the total length of the laser.

Thus the third factor (increasement of gain due to increasement of the

energy deposition density) goes away.

Concerning the second factor - it is the very fact that applying a

preionization or either increasing its power in most cases affects

lasers positively. Moreover the sharp edged shape of the electrodes

was often used in the laser technique with the aim to preionize the

discharge gap. The sharp electrodes were told to have different

properties: from the ability to emit electrons due to autoemission

to the ability to emit ultraviolet radiation due to corona discharge

taking place in the process of voltage grow before the main discharge.

It looks like the nitrogen laser with sharp edged electrodes has two

sources of preionization: the sliding discharge above the dielectric

between the main electrodes and the predischarge corona from their

edges.

The relation between their intensiveness/effectiveness is easy to

understand if we make (in mind) two experiments:

- To create a laser with dull electrodes (e.g. made of tubes)... In

the reality there's no need to perform such an experiment - it is

clearly known that such lasers exist and perform well. They show

good purple glow (volumetric discharge) and lasing. It means that they

have enough preionization for glowing discharge and presense of lasing.

- To assemble a laser with sharp electrodes and to test it in the

absense of the sliding discharge. Actually there are 1001 way to

suppress the sliding discharge or to make its preionization neglible.

One may increase the distance between the dielectric and the working

edges (i.e. increase the thickness of the electrodes), one may put a

narrow paper strip onto the dielectric between the electrodes; one may

create the electrodes of such a shape that the spacing between then

will become too large (size H at the pic1) etc, etc.

However it is unnecessary too, - at least in Alfonso Torres Rodrigues

blog, devoted to nitrogen lasers there described a lot of such faults,

including one of his very first tests, where the attempt to lubricate

the dielectric with oil caused suppression of the preionization and

absence of lasing. In such cases it appears to be impossible to get

even the glow, not to mention the lasing. I.e. the power or the

effectiveness of the sharp electrodes alone is not enough even for

obtaining the volumetric discharge type.

Here goes the conclusion: the preionization due to the corona at the

sharp edges is neglible when compared with the preionization due to

the sliding discharge radiation.... Second factor gone away.

As to the third factor - the deficiency of the field tension in the

discharge for the effective excitation of the nitrogen has already

became a legend. Actually the electric field strength needed for the

volumetric discharge ignition in the air is about 30 kV/cm (39 V/cm*torr),

and they say it needs much more. E.g. Jon Singer after the review of

the literature reports 86-100 V/cm*torr [see A Simple Nitrogen

Laser Using “Doorknob” Capacitors in a Voltage-Doubling Circuit, and with

Semiconductor Preionization, Primarily Intended for Do-it-Yourself Laser

Hobbyists ] However there exists a suspicion that even this value was

obtained merely as the ratio of the storage charging voltage to the

laser channel spacing. However one may recall that the field strength in

the real discharge has nothing to do with that. One may also remember

that the field tension having place in the common self sustaining

discharge is more suitable for effective excitation of vibrational

levels in the far infrared CO2 laser, rather than for excitation of

electron levels in the ultraviolet nitrogen laser. The energy height of

the vibrational levels is ~30 times lower than the height of the

electronic ones. One may come to a conclusion that thus the necessary

energy of the electrons will be 30 times higher. The same will also

be true for the E/p ratio. It means that the fields needes for the

optimal excitation of the electron transition levels in the nitrogen

laser would be as high as 1000 V/cm*torr. It is understandable that

such a field is unreachable whatever gases You use or whatever efforts

You put. It means that one can never jump across the optimum, and any

increasement of the electric field strength will increase the

effectiveness of the nitrogen laser.

It's to be mentioned here, that the electrical field by itself does not

excite any atoms. Only the electrons are responsible for that. (You

read "electric current") So it's of no importance whatever the voltage

had been applied across the laser channel before the current has started

to flow. It is important only how strong was the field inside the plasma

during the active stage of discharge glow. And this actual electric

field strength is extremely hard to affect. Any attempts to increase

the applied voltage are parried by the gas by practically instant

increasement of conductivity. Any excess of the feeding voltage are

dissipated on the internal resistance of the power supply, not on the

resistance of the plasma. And this plasma has much more reserves to

increase its conductivity, than we have ones for the reduction of the

internal resistance of the power supply (in our case - for the reduction

of the discharge time of the laser wings). So it is the game with one

gate. The only place where the speculations are possible is the real speed

of this "practically instant" reaction of the plasma. However judging

from the absence of the nitrogen lasers with really high efficiency

it is able to drop the excess of the voltage fast enough for us to

be unable to do anything with that.

Another way for the increasement of the actual field tension is

to change the composition of the gas mixture. It is classic to use

sulphur hexafluoride (SF6) for this purposes. The literature contains

number of reports that the presence of SF6 in the gas mixture

dramatically increases the efficiency of nitrogen lasers. Actually

SF6 would also come handy for spark gaps filling - it would allow to

have all the superiorities of pressurized spark gaps already at the ambient

pressure. The problem is only that it is hard to find a tank of SF6

lying readily on Your road. And it is hard to replace it with something

equivalent. There exist other gases with comparable electric strength

(sulfur dioxide SO2 ~150 kV/cm, some freones ~200 kV/cm), but the freons

tend to pollute everything with a soot appearing in the process of

their decomposition in the plasma. Evidently it does not make laser

tubes or spark gaps to work better. Sulfur dioxide SO2 is rather hard

to produce and it stinks. However its main decomposition product is

just the common sulfur, that is good dielectric and makes no harm.

Possibly SO2 is the additive of the choice for DIYers.

For obvious reasons the pressure changes are not the subject of the

discussion. First of all, we consider the atmospheric pressure laser.

Second - since only the electron energy is important rather than the

electric field strength, it comes that not the E itself, but only

E/p ratio is meaningful. And at normal pressure range it does

not vary.

However the things aren't as obvious with non-uniform field. First of

all one should keep in mind that with concentrating the field in one

part of the discharge (near the sharp edges) the field becomes weaker

in the other part. To illustrate this I'll begin with the fact that all

my high voltage experience gives the evidence that when the pulse is

fast enough the breakdown voltage becomes independent of the electrodes

shape. E.g. when You take a low inductance Marx bank and load it with

the low ohm or low inductance shunt, and then when You make tests for

sparks the length of those sparks is equal for ball electrodes and for

needle ones. (Its seems rather obvious, since with nanosecond pulses

there's no time for slow corona development or whatever. However I

havent yet found a reference for this phenomenon in literature. It's

probably too straightforward for authors to put on a red cloak of

Captain The Obvious and to cry out loud about it. So here for this

explanation I feel the need to refer to my own experience. For ones,

who love the punctuality, I'll say that I'm not sure whether this

phenomenon would stay right at too high field tensions, when a

sufficient role is played by explosive autoemission from the cathode.)

Further on if we take that the breakdown voltage really does not depend

to the shape of the electrodes, it comes out that in the laser with

sharp electrodes the most volume is filled with LOWER field than the

average field in the laser with dull edges.

It even can be proven.

Let it be that in the first case the field is uniform and equal to

ME (shortcut for the Medium Electricity):

------O MEMEMEME O------

If the inter electrode spacing is h and the voltage across the

electrodes is U then U=h*ME

Let it be that in the second case the field is non uniform and

equal to HE (High Electricity) in zone having radii r around the

electrodes and equal to LE (Low Electricity) in the last area having

the width h-2r :

------> HEHE) LELELE (HEHE <------

If the voltage across the electrodes is the same and equal to U, then

U=HE*2r+LE*(h-2r)

If we make an equation from the expressions for the first case and for

the second case we'll get:

h*ME=HE*2r+LE*(h-2r) => LE*(h-2r)=h*ME-HE*2r => LE=(h*ME-HE*2r)/(h-2r)

=> LE=(h*ME-2r*ME+2r*ME-HE*2r)/(h-2r)=>LE=(ME*(h-2r)+2r*ME-HE*2r)/(h-2r)

=> LE=ME+(2r*ME-HE*2r)/(h-2r) => LE=ME*[1+(2r-(HE/ME)*2r)/(h-2r)] =>

=> LE=ME*[1+2r*{1-(HE/ME)}/(h-2r)]

The expression in the curly braces is below zero, since HE>ME from

the statement of problem. It means that in the square brackets the unity

is summed with a negative number, and finally it means that LE<ME.

I.e. despite the fact that the field is strong near the sharp electrodes,

the field in the last (and largest) part of the laser channel is always lower than the one in laser with the uniform field.

Ant the first glance it seems that we can only loose the overall laser

output if we make the field strong in a small area and make it weak in

much greater area. However it's not necessary true.

If we divide the working volume of the laser V into the volume occupied

by the strong field Vhe and the volume occupied by weak field Vle

(and V=Vhe+Vle) then we can express the output energy of the laser as:

W1=Vhe*eff(HE)*w(HE)+Vle*eff(LE)*w(LE)

where eff(HE) - laser efficiency with the strong field and eff(LE) - efficiency of the laser with the weak field, W(HE) - energy deposition

in the area of the strong field, W(LE) - energy deposition in the area

of the weak field.

The same is for the laser with the uniform field:

W0=V*eff(ME)*w(ME)

where eff(HE) - the laser efficiency for the medium field and W(ME) is

the energy deposition in that medium field.

Now we can find a condition when the overall efficiency of the laser

with non-uniform field is higher than the one for the laser with uniform

field. For this we will assume that overall energy input is equal in

both kinds of lasers:

V*w(ME)=Vhe*w(HE)+Vle*w(LE)

Lets look at the "addition" of the output energy of the non-uniform field

laser in comparison to the uniform field one:

W1-W0=Vhe*eff(HE)*w(HE)+Vle*eff(LE)*w(LE)-V*eff(ME)*w(ME)=

=Vhe*eff(HE)*w(HE)+Vle*eff(LE)*w(LE)-eff(ME)*Vhe*w(HE)-eff(ME)*Vle*w(LE)=

=Vhe*w(HE)*[eff(HE)-eff(ME)] + Vle*w(LE)*[eff(LE)-eff(ME)]

In order for the effieiency of the non-uniform field laser be higher than

the one of the uniform field laser this "addition" is needed to be

positive: W1-W0>0, and thus:

Vhe*w(HE)*[eff(HE)-eff(ME)] + Vle*w(LE)*[eff(LE)-eff(ME)]>0 =>

=> Vhe*w(HE)*[eff(HE)-eff(ME)] > - Vle*w(LE)*[eff(LE)-eff(ME)] =>

=> Vhe*w(HE)*[eff(HE)-eff(ME)] > Vle*w(LE)*[eff(ME)-eff(LE)] =>

eff(HE)-eff(ME) Vle*w(LE)

=> --------------- > ---------

eff(ME)-eff(LE) Vhe*w(HE)

The translation of this condition from the math's to human language

sounds like the requirement for the laser effectiveness function to

grow so fast that the fraction in the left part of the inequality be

higher than the right side (the latter does simply express the ratio

of the energy deposited in the low field area to the energy deposited

in the high field area).

It is not reasonable to expect that I will solve all the plasma-kinetic

equations system, will get the explicit form of the eff(E) function and

will prove the validity of the inequality gracefully. I just mean that

in reality there may exist conditions, when the non uniform field laser

has higher efficiency than the uniform field one. And those conditions

take place when the efficiency grow strongly and non-linearly with the

electric field growth (and it usually comes true).

One more notice. I understand that all these maths could be done using

triple integrals from vector functions. However in order to illustrate

the principles the school math is more than enough.

* Why the inter-electrode spacing is equal to the half of the one in the

main spark gap?

Lets discuss a simple problem: a discharge of a capacitor through a

zener diode (see the figure below)

At the initial moment let the capacitor Co be charged to the voltage Uo.

Let the stabilization voltage of the Zener diode be U1 and let Uo>U1

(otherwise the current won't flow).

After the shortening of the switch some current i flows through the

Zener diode. Thus the power deposited in the Zener diode is U1*i.

The energy having been deposited in the Zener diode up to the full

discharge of the capacitor is equal to the product of the current and

voltage, integrated over the time. However U1 is constant and may be

taken out of the integral.

It means that the total energy having been deposited in the Zener diode

is equal to the product of U1 with the current integrated over the time.

The latter is merely equal to the charge that have left the capacitor:

Co(Uo-U1). (As You can see there's no need to know the current i and

its time dependency.)

So far the total energy deposited in the Zener diode appeared to be

equal toQ1=U1*Co(Uo-U1).

On the other hand the energy stored in the capacitor is Q0=Co*Uo^2/2.

The efficiency of the energy transfer from the capacitor to the zener

diode is:

U1*Co(Uo-U1) 2*U1*(Uo-U1)

eff= ------------ = ------------

Co*Uo^2/2 Uo^2

Using the school rules of the searching for extremum of a function

(take the derivative and zero it) one may find that this efficiency

is maximal (and equal to 50%) when the Uo=2*U1, i.e. when the charging voltage exceeds the voltage of stabilization twice.

What for we've discussed the problem of the zener diode? The reason is

that with taking into account the "E/p ratio constantness for a gas

discharge" the laser channel plays the role of zener diode in the

problem solved just above. I.e. the efficiency of the energy transfer

from the storage capacitor to the gas discharge plasma will be maximal

when the storage capacitor is charged to the twice of the voltage of the discharge sustaining.

However our laser isn't a simple charge transfer type. It has a Blumlein

circuit - the circuit, which is thought to double the voltage. Lets go

further to a bit more complicated problem (see the picture below).

Now the zener diode not only included to a Blumlein circuit, but

also connects to it not at the very beginning, but some time later,

at the moment 'to'. At the beginning the right and left capacitors are

charged to the voltage Uo. At this time the switch in the right

capacitor's circuit becomes turned on, and the voltage on this capacitor

UB begins to drop. Dependently to the relation of the RLC elements in

this tank circuit the voltage may drop exponentially (if the decay is

overcritical) or either by the cos(t/sqrt(LC)) law if the decay is

subcritical.

At some moment of time (still prior to 'to') the voltage difference

between left and right shoulders of the circuit reaches the laser

channel breakdown voltage (or the stabilization voltage, that's

equivalent). The gas discharge begins to evolve. Because it still

evolves the electric current is still neglible and the switch in the

zener diode circuit may be treated as open. Only after a time (namely

the gas gap covering time) the discharge finishes its shape and

begins to conduct - we may think that in our equivalent circuit the

zener diode switch have turned to 'on' state - i.e. the 'to' moment

of time have came.) Up to this moment the right capacitor has

discharged some more, so the voltage difference between left and

right capacitors would be not exactly equal to U1, but will be a bit

higher: UA-UB=U1+deltaU

After that all processes are so fast that we can neglect further

discharge of the right capacitor through the RLC circuit. Then all the

process may be treated as the discharge of the left capacitor into the

right one through the zener diode. If we designate the charge flown

through the zener diode as q, we can express the voltages on the left

and right capacitors as UA-q/C and UB+q/C. Apparently when the

difference of those becomes less than stabilizing voltage U1 the

current stops to flow and this condition may be used to calculate the

flown electric charge:

UA-q/C-(UB+q/C)=U1 => q=(UA-UB-U1)(C/2)

(Actually in case of the real gas discharge the current usually does

not stop after the voltage has dropped below its sustaining limit, it

just contracts into "bright arc". But from the our pint of view it is

invaluable since the further energy deposition is at least useless and

may be not taken into account.)

Similar to the previous problem the usefull energy deposition in the

zener diode is:

Q = q*U1 = U1*(UA-UB-U1)(C/2)

By variation of the spacing h in the laser channel we can vary the

voltage of the discharge glow (the stabilization voltage) U1. Let's see

what U1 is optimal (when UAand UB are given). If we take the derivative

of Q (over U1) and nullify it, we'll get the condidtion of the maximum:

U1=(UA-UB)/2

If we assume that up to 'to' moment the left capacitor has kept all

its charge (UA=Uo) and the right capacitor is fully discharged (UB=0)

then the condition of the optimum will look like: U1=Uo/2 - i.e.

breakdown voltage of the laser channel should be equal to a half of the charging voltage. And since the laser

channel and the main spark gap are filled with the same air at the same

pressure, it means that the interelectrode spacing in the laser channel

should be the half of the interelectrode spacing in the main spark gap.

The last thing left to understand is why on the Earth the voltage

on the right capacitor should be equal to zero? The deal is that the

energy input depends not only to U1, but also to the UA-UB-U1 difference.

The latter depends to how much charge will loose the right capacitor

during the laser channel covering time. The rate of voltage change on

the right capacitor is proportional to the current flowing in the RLC

circuit: (dUB/dt)=iB/C, and this current is at top exactly when the

voltage on the capacitor fly over zero (presuming the tank circuit

is subcritical).

Kinda that, guys.

* The charge transfer circuit

One of the least tolerable drawbacks of the discussed above scheme

of the laser (winged scheme aka voltage doubling circuit aka Blumlein

circuit) is the necessity to replace the dielectric periodically. Can

anybody somehow prolong its lifetime without lessening the output,

i.e. without reducing the voltage and without reducing the energy

input? It appears to be possible. It just needs the mylar to stay

under the voltage as short time as it can. In the Blumlein laser the

dielectric stays stressed during all the charging time. Ideally this

charging time should be as short as possible, that means fast charging

from some external capacitive storage.

Exactly this thing is done in so called "charge transfer circuit", that

is shown on the picture below.

(Next to the laser channel (to the right) the grounded plate designates

a preionizer)

The sharpening capacitor Cp (aka peaking capacitor, or, to be short, "the peaker") is usually made in the shape of a single plate having

the length equal to the length of the laser electrodes and the width of

10..15 cm. Actually it strongly resembles a wing of Blumlein type laser.

Charge transfer laser has only one wing. The second electrode is securely

connected to the common wire (to the 'ground' plate). That design of the

peaker provides the ability to discharge throughover that 1..2 nanoseconds

needed for the ambient pressure nitrogen laser.

On the other hand the storage capacitor Cs has not to be as fast. In

practice it is suitable to be made of commercial high voltage capacitors -

all kinds of doorknob TDK's, Murata's, KVI-3's, or either made of

(comparatively) low inductive film capacitors like Maxwells, K75-74 and

so on. The commercial capacitors are usually reliable enough to provide

the lifetime up to million pulses (if only the laser electrodes will

endure this without need of the repolishing.)

One may use a DIY low ESL capacitor (how to make it see here). However it

has low sense. Yes, such a capacitor can be made having even lower

inductance than a commercial one has, but the lowest possible storage

inductance is not the first requirement here. One comes to the charge

transfer circuit exactly to lower the requirements to the storage by

the price of the efficiency. And this allows to increase the lifetime.

And it's sad to mention but it's very hard for DIYer to compete the

commercial HV capacitors in the field of the lifetime.

Its obvious, that if the storage capacitor has not the lowest possible

inductance, it has low sense to cut the inductance of the spark gap. So

one can use here the most common spark gaps of the 'sphere-to-sphere' or

the 'sphere-to-plane' types. The rail type multi-gapped spark gaps are

too complex and may be avoided.

How it comes that without too much lowering of the inductance one can

create a working nitrogen laser that often has even higher power? The

figure below depicts two circuits.

A) - a charge transfer

circuit

B) - the Blumlein scheme

The stray inductance of the circuit of the Blumlein wing reverse charging

is designated as L2. The stray inductance of the charge transfer circuit

is designated as L1. In order to understand how to reach the same or even

higher power when L1>L2, let's calculate the usefull energy to gas input

for both circuits. The 'usefull' energy input - means the one taking place

during the time period shorter than that one-two nanoseconds, they always

talk about.

A priori (i.e. without any proof) we'll assume that wings CL and CR

of the Blumlein laser, as well as the wing Cp of the charge transfer laser

are capable to discharge in the required time. Actually this assumption

is trustworthy, as in both cases the wing is merely the planar

transmission line, and the transmission lines are usually thought to be

able to discharge in time equal to their (electrical) length divided

by the speed of light.

In this case the usefull energy input for the Blumlein laser can be

estimated as (see the previous part of the comments):

Qb=U1*(UL-UR-U1)(C/2)

and the one for the charge transfer laser:

Qct=U1*Cp*(Up-U1)

here C=CR=CL, U1 - the glow voltage for the discharge in the laser

channel, Up - the voltage on the peaker Cp achieved up to the moment

of the discharge ignition, UL-UR the difference of voltages on the

wings of the Blumlein laser also achieved up to the moment of the

ignition. It is clear that either Up or UL-UR are higher than the

laser channel breakdown voltage exactly by the value of the voltage

jump during the covering time tc.

The voltage jump can be estimated as the speed of the laser's wing

charge (recharge) multiplied by the covering time. In its own turn the

speed of charging/recharging may be estimated as the initial voltage

divided by the discharge time. If we take a quarter of the oscillations

period of the correspondent LC tank circuit as the discharge time, we

can get:

for the Blumlein laser: UL-UR-U1=tc*Uob/[(pi/2)*sqrt(L2*C)]

for the charge transfer one: Up-U1=tc*Uoct/[(pi/2)*sqrt(L1*Cct)]

where Uob - the initial voltage of the Blumlein circuit, Uoct - the

initial voltage of the charge transfer circuit, C - the Blumlein wing

capacity (does not matter the right one or the left one since they are

equal), Cct=Cs*Cp/(Cs+Cp) - the series capacity of the peaker with the

storage (from the point of view of the current in the Cs-L1-Cp circuit

they are connected in series).

One could also note that the recharging speed is nothing else than the

current in the circuit divided by the capacity. From here it particularly

follows that the energy input to the gas is at the maximum (when all other

conditions are fixed) if the ignition of the laser channel takes place

at the moment of maximum of the current in the tank circuit. And that

maximal current might be estimated a bit more precisely using the energy

preservation law (C*U^2/2=L*I^2/2), but this approach will give us the

relation between the charging voltage and the breakdown voltage. And we

don't need it right now since we're searching when the charge transfer

laser has higher energy deposition regardless to its efficiency.

With knowing the voltage jump during the covering time we can now write

the usefull energy depositions:

for the Blumlein laser:

Qb=U1*(UL-UR-U1)(C/2)=U1*(C/2)tc*Uob/[(pi/2)*sqrt(L2*C)]

for the charge transfer laser:

Qct=U1*Cp*(Up-U1)=U1*Cp*tc*Uoct/[(pi/2)*sqrt(L1*Cct)]

Now let's look when it can take place that Qct > Qb, i.e:

U1*Cp*tc*Uoct/[(pi/2)*sqrt(L1*Cct)] > U1*(C/2)tc*Uob/[(pi/2)*sqrt(L2*C)]

If both lasers have the same spacing in their laser channels, the glow

voltage and the covering time will be the same. So we can reduce the

expression by U1 and tc. In addition let's remove the (pi/2) too:

Cp*Uoct/sqrt(L1*Cct) > (C/2)*Uob/sqrt(L2*C) =>

Cp^2*Uoct^2/(L1*Cct) > (C^2/4)*Uob^2/(L2*C) =>

Cp^2*Cs*Uoct^2/(L1*Cs*Cct) > 2*C*Uob^2/(8*L2) =>

Cp^2*Eoct/(L1*Cs*Cct) > Eob/(8*L2)

where Eoct=Cs*Uoct^2/2 - the initial energy stored in the charge transfer

laser and Eb=2*C*Uob^2/2 - is the initial energy stored in the Blumlein

laser wings.

Eoct/Eob > (L1*Cs*Cct)/(8*L2*Cp^2) =>

Eoct/Eob > (L1*Cs*Cs*Cp)/(8*L2*Cp^2*(Cp+Cs)) =>

Eoct/Eob > (L1*Cs*Cs)/(8*L2*Cp*(Cp+Cs)) => ...

Eoct/Eob > (1/8)*(L1/L2)*(Cs/Cp)/(1+Cp/Cs)

Now the left part consists of the charge transfer laser's stored energy

divided by the stored energy of the Blumlein laser. The left part keeps

the inductance of the charge transfer laser charging circuit divided

to the inductance of the Blumlein laser reverse circuit, and this ratio

is multiplied by some factor, that depends to the relation between the

peaker and storage capacities.

One can now see that the slowness of the laser with the higher

inductance may be compensated by the higher initial energy stock. This way

one can achieve high output energy of the charge transfer lasers by

loosing the efficiency.

One can go even further and assume that Cp=C (it means that, as it

oftenly happens, the sizes and shape of the Blumlein laser wing are

similar to the ones of the charge transfer laser wing). In this case if

in our final expression we return from the energies to the "C*U^2" terms,

if we note, that in most cases Cs>>Cp and therefore (1+Cp/Cs)->1, then

with taking into account all this stuff we'll get:

Cs*Uoct^2/[2*C*Uob^2] > (1/8)*(L1/L2)*(Cs/Cp)/(1+Cp/Cs) =>

(Cs/Cp)*Uoct^2/Uob^2 > (1/4)*(L1/L2)*(Cs/Cp)/(1+Cp/Cs) =>

Uoct^2/Uob^2 > (1/4)*(L1/L2)/(1+Cp/Cs) =>

Uoct/Uob >~ (1/2)*sqrt(L1/L2)

Now one can see that the main resource for the mentioned above

increasement of the energy, needed to compensate higher inductance, lies

not in the increasing of the storage capacity Cs, but in the increasement of the

power supply voltage Uct. It finely correlates the typical design of

the charge transfer laser: large and very high voltage rated storage

capacitor (preferably of the commercial type), that uses a common

(pinpoint type) spark gap to charge a peaking capacitor having the shape

of a metal foil wing placed above a leaf of thin dielectric. One of the

laser electrodes is securely connected to this wing all over its length.

The other laser electrode is similarly connected to the common wire

("ground" plate). It is obvious that the voltage on the peaking capacitor

does never exceeds the breakdown voltage of the laser channel by any

significant value. This allows to design the peaker to be rather low

voltage rated, i.e. having thin dielectric, so its specific capacity

can be high enough.

Here is the photo of a charge transfer circuit laser.

Four 2 nf 40 Kv rated Murata's serve as the storage capacitor. The

spark gap is of the "ball-against-plane" type. The peaker wing is sized

as 30x10 cm. The dielectric is a mylar sheet 0.12 mm thick. When the

spacing in the spark gap is as hig as 12 mm the output energy of this

laser does slightly exceed the output of the Blumlein laser described

above. The size and shape of the electrodes are the same in both types

of lasers. The optimal spacing in the laser channel is higher than the

one in the Blumlein laser by 0.2..0.3 mm.

Due to the higher initial voltage and higher stored energy the

charge transfer laser has the repetition rate nearly 10 times lower than

the one for the Blumlein type laser when fed from the equivalent power

supply. In almost 2 years of operation its dielectric has never failed.

However it does not help to get rid of the periodic electrodes cleaning.

This problem arises here even more sharply than in the winged laser.

There essentially exists a problem of an excessive energy deposition.

In the Blumlein type laser the wings come to the voltage equilibrium

in a short time and the energy deposition to gas stops. But in the charge

transfer laser, even when the peaker has dropped its excessive charge

throughover the laser channel, it stays connected to the powerfull and

slow discharging storage capacitor Cs. The gas discharge continues to

glow (or burn?) until the total Cs+Cp capacity drops its voltage to

the low enough values. I.e. the total energy deposition (the sum of

the fast one and slow one) will be by the next value higher:

X = Cs*U1*(Uoct-U1)/{U1*Cp*tc*Uoct/[(pi/2)*sqrt(L1*Cct)]} =>

X = Cs*(Uoct-U1)/{Cp*tc*Uoct/[(pi/2)*sqrt(L1*Cct)]}

If we neglect the laser channel breakdown voltage in comparison with

the initial voltage (i.e. if we take that Uoct-U1 ~ Uoct, it means that

we consider the 3 mm of the laser channel spacing to be neglible when

compared to the 12 mm of the main spark gap spacing), then:

X = Cs/{Cp*tc/[(pi/2)*sqrt(L1*Cct)]} =>

X = (Cs/Cp)*{(pi/2)*sqrt(L1*Cct)/tc}

The value on the right side of the expression is the ratio of the

storage capacity to the peaker capacity multiplied by the ratio of the

storage discharge time to the covering time. Usually both of these factors

are high enough to securely provide the excess of the energy deposition

above the threshold of the discharge contraction. In its own turn this

leads to the accelerated erosion of the laser electrodes.

Here comes one curious conclusion: in order for not to heat the gas in

excess, the storage capacity should be LOWER than the peaker capacity.

Evidently the voltage on the storage should be raised correspondently (and

it is not always easy to do). When the storage voltage is large enough the

storage itself may be better designed as a Marx bank generator, and this

design we can see in the most advanced nitrogen lasers.

One more notice to the end of this part:

here it was always assumed that the covering time is always less than the typical

time of the laser wings charging or the charging time of the peaking capacitor.

Otherwise the above formulas arent correct. However this condition fulfillment

is trustworthy for the ambient pressure nitrogen lasers. From the difference of

the spacings between the laser electrodes at both ends of the laser when the

slope of the electrodes is optimal (0.2..0.3 mm per 30 cm of length) we can

estimate the covering speed as high as 0.2..0.3 mm/ns, and therefore the covering

time will be ~10 ns. On the other hand if we estimate the discharge circuit

inductance to be ~20 nH, then the wing voltage reversal time will be

pi*sqrt(LC)= 3.14*sqrt(6nF*20nH)=34ns. For the charge transfer laser this time

will be even higher for the obvious reasons. However if we take that the covering

speed depends only to the electron velocity (read this as E/p ratio), i.e. it

practically does not depend to the pressure, then in low pressure nitrogen lasers

with their huge spacings (up to 10..30 mm) this condition may appear to be invalid.

The value of 0.3 mm/ns taken from the difference of spacings in 30 cm long laser may seem to be doubtful for some extent. Especially if one takes a look into the graphs given in Bergmann’s article devoted to his microlasers. The current to voltage delay there appears to be clearly 2 ns for 2 mm of spacing, so the covering speed seems to be equal 1mm/ns – the value given in most textbooks, and also the one I used earlier. This one looks more trustworthy but requires the explanation why the optimal difference of the electrodes spacing is less than 1 mm per each 30 cm of the laser channel length. The case may be due to the discharge instabilities at higher spacings.

Its up to You what value of the covering speed to use (0.3 mm/ns or 1 mm/ns), it only affects the resulting digits but does not change the tendencies.

* Gas mixture

Despite the fact that the laser was initially intended to be capable

for operation with air only (and without all that gas tank husbandry and

other excesses) it was interesting how much output can it give if working

with technical grade nitrogen.

A special lid was developed to cover the laser channel. It has a special

hose and allows to use the laser while it is being blown through by the

gas mixture from an external vessel (from a gas cylinder or an automotive

tyre filled with the premixed gases).

It was found out that when the laser is being continuously blown by

the nitrogen, the dye cells are able to lase at a distance three times

greater than during normal operation. With taking into account the

"inversed square of r" law it means that the laser's power rises almost

by ten times. The nitrogen laser's spot and the spots of dye lasers driven

by it have strongly improved their visual brightness too.

When the working gas is the common air with its oxygen having been

burned out by combusting organic fuel (so called "combustor" gas) the

laser works almost as effectively as with air. (I.e. "combustor" does

not improve anything".)

Tests on the helium with air mixture have shown that the power of

the laser begins to rise when there is less than 20% of air in the

mixture. The mixture containing air:helium = 1:10 (by volume) the power

is comparable to the one with pure nitrogen (or to be more precise the

dye cells lase at similar distances. The power/energy can only be treated

as "the same" if the pulse duration does not vary here.)

For the reasons mentioned above it is very interesting to test the

laser with N2:SF6 and N2:SO2 mixtures. However since the laser is not

vacuum tight the exhaust of the sulfur dioxide into the air would require

very vell vetntilated premises. And I have no idea where to get a tank

of SF6.

* Scaling

It is usually assumed that since the excited nitrogen lifetime is

very small at atmospheric pressure, the length of the laser should not

exceed a certain value. The limiting length is commonly taken as long as

30 cm - the distance that light travels in a single nanosecond.Actually the same phenomenon (the traveling wave of the electric

discharge ignition), that allows You to tune the laser for the maximum

light in the desired direction only by slanting the electrodes, does also

allow to synchronize the excitation with the traveling light over the

very significant lengths. At least up to meter (tested) or may be several

meters (untested). I.e. the laser can e easily scaled by length. If the

length is reasonable (longer than 10..15 cm) the power grows linearly with

the length of the laser. However the excessive factor of two or three in

the laser's output gives a very little addition to its possibilities.

On the other hand, such a large thing as a meter long laser on Your

table will definitely not make You happy.

If trusting the scientific papers, the laser can be easily scaled

towards diminishing of length. One should keep in mind that the "threshold"

length is somewhere between 5 and 10 cm and one should use resonators and

mirrors if the laser becomes so small. (I know, i know, the superradiance

(aka ASE) is the phenomenon without the threshold. However at some point

the output anyways begins to degrade dramatically.)

In theory the laser should be easily scalable to the width with the