What is to be done in order to build power a unit for some gas laser?

- To find (or to develop) a sheme.

- To get an integrated circuit (NE555, TL494 etc...)

- To obtain MOSFET'S or IGBT's.

- To make a pc-board, to etch it, to drill a bunch of holes, to solder...

- To tune, and to burn out a set of expensive MOSFETs...

The more You think about it the less will remains for power unit making,

and only fantasies stay in Your head: "it would be good to..."

The device being described in this guide appears to be almost ethalon of

the duct-tape-technologies: You get this, take that, connect and obtain

something very different. Maybe You could refurbish it a bit with a file.

(In our case - with a soldering tool.)

1. RESOURCES.

For the work we shall need following:

- electronic transformer for feeding low-voltage halogen lamps

- an ignition coil

- halogen lamp 500 W 220 V (or 127V if your mains are of that type)

- halogen lamp 30 W 12V

- a plug (compatible with Your mains of course)

- A piece of plastic to set up all those goods

- Common electronic/electric tools

It is enough to power some devices, that eat alternating current (e.g.

continuous wave gas lasers). If You need rectified current, You also need

- i) a set of fast high voltage diodes

- j) a high voltage capacitor (or a pair of them if You intend to use

voltage-doubler)

The electronic transformer should be choosen with taking into account

Your needs (so select desired declared power) and funds. Tashibra is cheap,

but You may discover unsoldered parts inside it. The pink Feron is

reliable, fetish, but expensive. Beware that if You choose too low

proclamed power of the electronic transformer You may face the necessity

to wind too much turns into its windings (like 50 or above) and You

may feel too lazy to overcome this.

For the example let's take a pink Feron rated at 250W.

> >

One more thing. For this guide not to turn out to be a poor cyber poem

like

Electronic lamp transformer, a transformer the transformer,

The transformer, the transformer, electronic lamp transformer...

Let's call the electronic transformer as ET-unit os simply ET.

The Ignition coil must have closed (E-type) core. The "two-horned" ones

are better than "single-horned" ones. Double horned's are stable at higher

voltages. Vhen voltages are moderate (like 10..15 kv) single horned ones

are usable, provided that it has a core with closed magnetic circuit.

Halogen lamp 220(110) Volts, 500 Watts may be of any type, it is used as

a preserve resistor (ballast). If something goes wrong the lamp will light up

and save your head from being hit with pieces of burning capacitor.

It has an advantage that in cool state it barely eats energy, and when lit

it can endure pretty high power.

A 30 watt halogennie is needed to switch the power unit on. It is due to

the fact that ET-unit circuit is designed with keeping in mind that it

should turn off when loadless. And it does. However typical hv load

(gas or vacuum tube or discharger) begins to conduct when voltage is

applied. To apply voltage the power unit must work. For power unit to

work the load must conduct. For the load to conduct the voltage must

be applied....

To exit from this closed circuit we use an auxiliary loading - the

small lamp. There certainly exist other ways to force the ET to working

state, but they are more complex. What can be simplier than a lamp and

two turns of wire - I can't even imagine.

Don't forget that the lamp should be 12 volts rated. If it's rated to

110 or 220 volts its winding will contain too many turns.

To make connections and to wind transformer use a wire having not less

than 0.3 sq.mm. cross section.

Diodes may be of any type provided that they have 'fast' or 'ultra-fast'

in their description. You will probably choose diodes with highest possible

reverse breakdown voltage (Urev). If still Urev is below Your needs, You

will assemble them into stacks.

In the most ignored cass one may set up a rectifier even without any

diodes. One can use assymmetric "point-to-plane" discharges. The example is

there however the device is large and unreliable.

One can use commercial or hand made capacitors. Here even exists a guide how

to make a high voltage capacitor at home. In the rectifier You can ignore the

inductance value of the capacitor, so feel free to choose any, that has necessary

working voltage.

2. THE ASSEMBLAGE.

There are two choices. For startig ones and for ones, who had burned out an

ET-unit (Of course You can dismantle one from the very beginning for not to

wait for one to fail... If things come good none of them will fail at all.)

In the second case You already have a toroidal transformer from the inside

of an ET-unit, and You have the opportunity to make all things outside the

ET box. It is certainly safer and preserves the good look of the ET-module

(if there is anything to preserve)

Let's start with the first case.

- Open the ET-unit. It may be different what You will see there. The guts

of the Feron are shown below:

But independently of the ET type You will see large ring magnetic core, where

some coils are wound. This exactly is a toroidal transformer. We are going

to solder it out and to refurbish. When soldering it out be sure to remember

(better to write down) which leads of the transfoemer to what points on the

board were connected.

The transformer of ET-unit usually contains two coils. The primary (the one

wound by rather thin wire and containing 70-150 turns) and the secondary

(wound with a very thick wire or either with a several wires in parallel,

it usually contains 4 to 6 turns). We won't use the secondary, and it

should be removed.

- Solder the toroidal transformer out.

There will be difficulties when unsoldering thick wires of the secondary.

Use 100 watt solder or a gas-torch. Try not to damage the pc board.

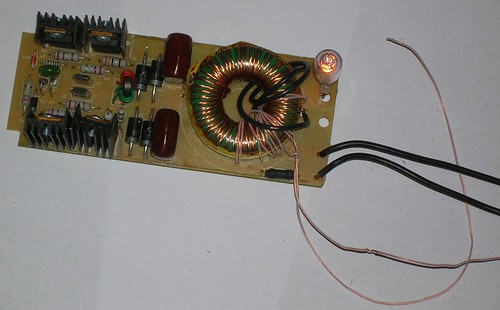

The photo below shows the pc board of the ET unit with the transformer

removed, and the transformer itself.

- Remove the secondary coil (don't forget to write down the number of

turns it had)

- In place of the old secondary wind a new one. The number of turns in it should be 2..3 times greater than in old one (In our case there were 4 turns

and we will make 10 turns) If possible leave the pretty long leads in order

to be able to make more turns if needed.

- Add one more (tertiary) coil. The number of turns ther should be a half

of the one in the old secondary. (In our case it was 4 turns, so we shall

wind 2 turns)

As the result the transformer looks like that:

- Install the transformer back onto ET board. (Solder the leads of primary

exactly to the same holes from where they were soldered out.) Solder the

12 v 30 W lamp to the leads of tertiary. And connect the ignition coil to

the leads of secondary.

Hereby the circuit shown below appears to be assembled.

It gives 12..20 kV of alternating rather high frequency (20..60 kHz) current

on the leads of the ignition coil. If You need only alternating current, then

all You need is to adjust the output voltage.

Connect a kilovoltmeter capable to ac-voltage measurements to the output of

the ignition coil. It may be of electrostatic type, or one having internal

rectifier. However You surely have no kilovoltmeter at hand.

Then use a spark gap to measure the voltage. The spark gap should have

spherical electrodes, and when the gap between them is about 1 cm the voltage

per unit of breakdown length is ~20 kV/cm.

Set the gab between balls to match Your desired voltage and adjusting the

number of turns in the secondary of the toroidal transformer set the output

to just above the one when first sparks appear between balls. Watch carefully

the ballast (safety) lamp. If it is dark or dim glowing - all's ok. If it's

lit brightly, it means that the ignition coil (together with ET unit) is

owerpowered and the circuit is not workable longer than for several seconds.

If all parts are in good condition, it means that the highest possible

output voltage is achieved.

The spark gap type of voltage measurements gives adequate results only when

there is no intensive preionisation. It may not be true If Your wires are

coroning. In that case even at rather low voltage there may be spectacular

fireworks.

|

|

In order for stop the corona it is robust (but not necessary) to use hv wires

from a car ignition system, or old tv cable.

Let's assume that in process of tuning Your ET-init got dead. And You decide

to fry the next one.

But now You have free toroidal transformer, and now there's no need to crawl

into the ET schematic.

- Remove coils from the toroidal transformer. We will use only its core.

- Wind tree coils onto the core.

Coil I must contain the same number of turns, that was in the secondary

(output) winding of the toroidal transformer before refurbishing.

(In our case - 4 turns). It's good (however not necessary) to add a pair

of turns more. Let's assume that we put N turns into coil I.

Then coil II must contain two..three times more turns (2*N..3*N), and

coil III must contain half of that number (N/2).

The photo below shows the refurbished toroidal transformer for Feron ET-unit.

Its coils contain 6, 14 and 3 turns correspondently.

- Connect the coil I of the toroid to the output of the ET unit,

Connect the coil II to the input of the ignition coil. And connect the

12 v halogennie to the leads of coil III.

Don't forget to connect the ballast lamp into the feeding circuit of

the ET-unit!

You will obtain the next circuit:

- The next actions are the same as in the first case. With keeping in

mind the necessary output voltage, adjust the number of turns in coil II.

(I'm sorry for Your long waiting for those photos, but it took pretty much time for me to fry the next electronic transformer and to obtain a free toroid)

3. IF A RECTIFIER IS NEEDED.

A rectifier of any classic scheme may be connected to the output of

the ignition coil. One should remember that ET-unit provides a symmetric

signal. It particularly means that the rectifier diodes have to endure

the doubled output voltage (the reverse halfe-wave voltage added to the

charge of the output capacitor). OTOH voltage doublers and multipliers

fairly double and multiply the voltage (by the number of cascades).

It is better than in case of blocking-generators or flyback schemes.

Here are the examples of rectifiers:

At the schematics the amplitude ac voltage is shown (the one that You

measure by the sparklength) so the output voltage doesn't need to be

multiplied by "square root from two" as it would be in case of

effective voltage.

If You use weak diodes, rated to currents below 100 mA) and load the

curcuit with a spark-gap (the circuit must endure shortening), then add

some 1 Megaohm resistor in series with diodes. Length of that resistor

should be over 3 cm in order to avoid sparking.

Powerfull diodes (HER's, R3000's, R5000's, etc) are rather durable, so

the ignition coil fails first.

The diodes have to work with frequences over tens of kilohertz. If there

is a word 'fast' or 'ultrafast' in the diode's description - it is good.

Otherwise You should check the datasheet on the diodes.

When collecting (rather) low-voltage diodes into stacks, use a number

by 30%..40% higher than needed (than N=2*Uout/Urev, where Uout is rectified

voltage, and Urev - is permitted reverse voltage of the diode). Such

an excess will allow You to not bother with resistor balancing of the diodes.

Naturally all commercial rectifier stacks utilize this approach. There are

no resistors inside.

Single horned ignition coils reliably endure outputs up to 15 kv.

Double horned ones - up to 35 kv, that with voltage doubling rectifier

delivers up to 70 kv. (Think carefully whether You need such a voltage

or not. With voltages over 45 kv length of sparks, especially sliding

ones, rises greatly, and it may cause You to fail with control over this

voltage.)

4. MEASUREMENTS.

The most simple way to measure the output voltage is to estimate it by

its sparklength. In handbooks on high voltage technique and over the

Internet there can e found the tables with dependencies of breakdown

voltage to the diameter of ball electrodes and to distance between them.

Precision of the method is about 20%, that is usually enough for DIY'er.

Yes, I have a gigaohm resistor and microampermeter. In addition the

gigaohm one consists of ten 100 megaohm pretty long resistors, and all

are sealed into a tough epoxy brick.

However I have already seen corona directly on microammeter arm, and

since that I don't believe in its readings. KILOVOLTMETER MUST BE LARGE.

Otherwise it does not work properly. Surface leakages do also make the

presicion of measurements low. The ballast resistor having many

fingerprints cunducts mostly by ithe dirty surface, and this its resistance

is dependent to voltage and generally unknown.

5. MODIFICATIONS.

- Power multiplication. If You need óìóò highóê power and use a rectified

output, You can sum the power of multiple units as shown below.

However one should note that in order to achieve reliability the power

load per unit over than 60% of the advertised power of that unit should

be avoided.

Also note, that it is senseless to try to pump one ignition coil with

plurality of the ET units - the silly one is already hot, when powered

by single ET. If You drive it to 400..600 Watts, You will burn it to ashes.

- Alternating current power multiplication is not so trivial. ET-units

will oscillate at different rates and will rather absorp each other power

than sum it. In order to achieve power multiplication with AC one should "phase" the ET-units.

However some interesting results can be obtaines from the scheme of series

connection of two coils.

Yes, I am no more impressed py the sparks of school electrostatic machine.

It's quite easy to surpass it greatly.

Both ET units appeared to be coupled by common current through the

common load. Thay can even autophase in a certain range of loadings.

Anyways the peak voltage is equal to the sum of independent output

voltages of both schemes. In case of phased ones it is achieved on

peak of oscillations, and in case of unphased - at the peak of beatings.

For the circuit be more strong electrically, You need to connect those

leads of (secondaries) coils that have waker insuation. In case of

single horned coils, connect their cores. In case of double horned ones

inspect carefully their design to find out what end to connect, and what

end to use for output... And yet You can make an error.

6. SAFETY.

Damn, it's dangerous! Be carefull and be clever.

7. ATTENTION!!!

Recently the market is full of "DC-versions" of electronic transformers! They are completely unable to drive an ignition coil when used in the schematics with an external intermediate transformer! An example of such a device is shown on the photos below.

The right part of the board contains the same circuit that did appear in older versions of electronic transformers. And the left part of the board seems to contain a synchronous rectifier. The device is still usable for our purposes when having been prepared by the algorythm with refurbishing its internal toroidal transformer. After making a new secondary winding for it do not solder its leads into the board (as it was suitable to do with the elder versions). Just make the leads to come out of the casing and use as usual.

<< HOME PAGE |