|

Cross charge (x-charge) laser design is rather widely known and used. A

good example of its application is technology laser LANTAN. Its schematics is

given at the figure below (cited from [1]).

The scheme of gas-discharge chamber of "LANTAN-2M" laser. 1 - the body of the

chamber, fiberglass plastic; 2 - ionization electrode; 3 - ionization

electrode terminal,; 4 - insulator (silica, glass); 5 - cathode of the main

discharge, 6 - anode of the main discharge. (The picture is cited from [1]).

Another good example is a laboratory laser designed by authors of [2]. I

think it makes sense to put its scheme here too (see the picture below).

Scheme of the pulsing ionization.

B) Discharge chamber. 1 - main electrodes (bronze); 2 - coolers (contain

water); 3 - dielectric walls of the chamber (alund ceramic, 1 mm thick).

The idea of the scheme is that the barrier discharge is responsible for the

ionization of the gas, so the main discharge can have non self sustainable form.

(Reminder: Barrier discharge is that kind of gas discharge, where the

electrodes are insulated from the plasma by a dielectric layer. Obviously this

type of the discharge can exist only when being powered by alternating or

pulsed current.)

In the more wide sense the scheme has two modes of operation:

A) The mode with self sustained discharge, preionized by a barrier discharge;

B) The mode, when the main discharge is completely incapable to self sustain

and it is fully controllable by the external ionization formed by the

barrier discharge.

In the mode A the scheme looks attractively to be applied in some TEA laser.

But in practice the multiplication ratio (the value equal to the energy

deposition of the main discharge divided by the energy deposition in the

preionizing discharge) appears to be small and degrades seriously with minor

additions of electronegative gases to the mixture, Moreover the main discharge

strongly tends to form a sliding discharge along one of the preionizing

electrodes. One can note that there exist methods of struggle those drawbacks,

but if we apply them the scheme becomes complicated, requiring precise timing

of the discharges, and still it remains very sensitive to the gas mixture

contaminations. I can say for example, that I was unable to get any lasing in

the x-charge lasers designs on air with CO2 mixtures (and even on nitrogen with

CO2) at the pressures over 250 torr.

Another interesting field of application may be found among the high

(average) power continuous wave (CW) or quasi continuous wave (QCW) lasers

working at low pressure. These lasers have more appropriate conditions for the

x-charge design. Apriori they use low pressure and helium. The helium is

unavoidable if one hopes for the decent output power. It provides the gas

mixture with the high thermal conductivity, needed for the cooling. The

pressure should be low just due to internal laser circumstances: the lower

the pressure - the higher is the upper laser level lifetime. In a certain

pressure range the emission cross section rises with the reduction of pressure

too. One and another allow us to reach the lasing threshold at the reasonable

levels of pumping, when the laser gas mixture is still at reasonable

temperature, and the laser chamber is still not molten. (This limitation has

no effect in the short pulse (TEA) systems, where the megawatts of pumping

power are on only for a few microseconds, and can not produce a sufficient

overheat. On the other hand in CW and QCW systems each kilowatt of pumping

power put the construction into heavier and heavier conditions, more and

more hard to survive.)

Since the pressure is low and the gas mixture is full of helium, there are

no principal difficulties for the use of the x-charge design. The suitable mode

is B, moreover than A mode is just inapplicable here, due to the fact that the

discharge glows continuously of for hundreds of microseconds, and these

periods of time are more than enough for the contraction of the most uniform

(at the initial stage) discharge.

Why one should seek such an exotic design for the continuous reduced pressure

laser if we have ye oldie tubular longitudinal scheme?

First of all the feeding voltage. The meter long longitudinal laser requires

almost kilowatt of power supply at 15..20 kV for a commercial tube and at over

35..40 kV for the amateur one (due to the gas contamination). And the laser

with the transverse discharge, having the width of 30 mm, promises to be

operational at 1..2 kV. It means the use of affordable microwave oven

transformer instead of the sophisticated high voltage unit. An additional

bonus will be that one can slightly increase the working pressure and thus

reduce the quality of the vacuum pumps being used, and also prolong the

lifetime of the gas mixture. Need to say that the mentioned transversal

discharge has the stability out of its distinguishing features even at

low pressures, It means that one needs some means of stabilization. Such

as sectioned electrodes with resistive ballast, or the usage of non self

sustain discharge type, exactly as it's offered here.

The last but not the least fact is that the geometry of the laser channel

in the form of narrow gap between two heat conducting planar walls is well

suited for the gas cooling. Let's for example take a common tube-shaped

laser: the ratio of the temperature difference deltaT between the center

and the wall divided by the total power Q of the uniformly distributed heat

source Q (in other words the thermal resistance of the cylindrical gas

column) does not depend to the tube diameter and is equal to:

Rt = 1/(4*pi*L*lambda)

where lambda [W/(m K)] is the heat conductivity of the gas, pi=3.14 is the

well known "pi" number, L is the length of the gas-discharge tube. (This

formula is quite easy to be derived from the basic heat conductivity law,

so there's no sense to make reference to any sources).

The independence of the thermal resistance to the diameter of the cylinder

may be comprehended from the next considerations: the area of the cooling

surface grows with the increasement of the diameter, but the distance for

the heat to pass does grow with the same rate. As the result the total

resistance does not change.

If we now fix the top allowed gas temperature Tmax, we'll get that the

top allowed energy deposition should not exceed the next value:

Qmax = (Tmax - Tout)*(4*pi*lambda)*L/(1-eff)

where Tout - is the temperature of the (outer cooled) wall, eff - the

efficiency of the laser.

The obtainable laser output will then have the next form:

Wmax = eff*Qmax = eff/(1-eff)*(Tmax - Tout)*(4*pi*lambda)*L

This relation explains the well known limitation of the (diffusion cooled)

CO2 lasers: "the output power depends only to the length of the tube, and the

factor of this dependency describes the quality of the laser, but generally

does not exceed some limiting value."

One may make the numeric estimations. First of all lets neglect the

dependency of the efficiency to the gas temperature and assume that eff = 0.1 = 10%. Then we'll postulate that the gas heat conductivity is determined

by the buffer gas only. It may be helium (lambda = 0.147 W/(m K)) or nitrogen

(lambda = 0.0315 W/(m K)) or either argon (lambda = 0.0164 W/(m K)). Lets

take that Tout = 20oC and Tmax = 200oC (the people's opinions on the Tmax differ

strongly, but here we take rather "classic" value [3]):

| buffer gas |

He |

N2 |

Ar |

| Wmax/L W/m |

37 |

8 |

4.1 |

The layout is totally different in case the active zone of the laser has the

shape of the planar plate (with thickness a, wideness b, and length L), being

cooled from both sides. From the hat conductivity law one can get:

Rt = a/(8*b*L*lambda), or Rt = a/(8*S*lambda)

where S is the area of the projection of the plate "on the top view".

Hence that energy input into the plasma will be:

Qmax = (Tmax - Tout)*(8*S*lambda)/(1-eff)/a

and the laser yield:

Wmax = eff*Qmax = (Tmax - Tout)*(8*S*lambda)*eff/(1-eff)/a

The obtained formula can be interpreted as the proportionality of the laser

output to the area of the surface being cooled. But one may go further and

divide the obtainable laser power for the planar geometry by the obtainable

laser power for the tube design:

(Tmax - Tout)*(8*S*lambda)*eff/(1-eff)/a 2*S/a 2*b*L

---------------------------------------- = ----- = ------- = (2/pi)*(b/a)

eff/(1-eff)*(Tmax - Tout)*(4*pi*lambda)*L pi*L pi*L*a

I.e. the laser, having its active medium in a shape of thin planar layer,

allows to get power from the unit of length greater by (2/pi)*(b/a) times than

the one, obtainable from the common pipe-like laser.

The (2/pi) factor essentially describes the difference between planar and

cylindrical shapes in the relation to the heat conductivity, and the (a/b)

factor (also named as "aspect ratio") describes the elongations of the

laser channel cross section.

For example if the thickness of the plasma column is 3 mm and the wideness

is 3 cm, the aspect ratio will be equal to ten, and this tube will allow 6.3

times more power from the unit of length than the common cylindrical one. E.g.

a meter long tube will allow to get 230 W of power in the contrast to 37 W

from the common one. (Of course if other sources of losses won't interfere)

One may comprehend the nature of this gain in the next way. Let's assume

that we want a huge power from the unit of the laser length, but for some

reason we have to stick to the cylindrical geometry. The readily coming solution

is to take N laser tubes and to put it into one harness in parallel. The batch

of tubes not necessary must be three dimensional. Lets put the tubes on the

table top tightly one near another. The next step is to eliminate the walls

between the adjacent tubes. We'll loose some some cooling (which otherwise

would take place on that walls) but we will gain the integrity of the laser

beam. Maybe it will have an uncommon shape (rectangular section) but still

it will be the single beam, coherent to itself. On the contrary in case of

N tubes we would have N independent beams with all related problems in

focusing them into one point.

Trust me, I had no intention to bother anyone with considerations and

derivations, but it was necessary to point out the essence, for one to

understand the reasons forcing to test the lasers of uncommon shapes. Now

this is done and we could proceed to the results of the tests, but one

more notice before this. I should say at the very beginning that the task

of "outperforming the commercial lasers" is not considered seriously here.

Indeed I got used to obtain efficiencies being one order of magnitude lower

than ones of the commercial grade devices. Since that I would be glad if

my tubes (abusing the benefits of the planar design) could even approach to

the parameters of the commercial cylindrical lasers.

1. Laser cells

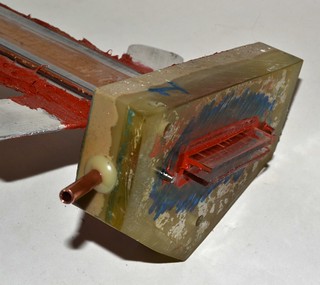

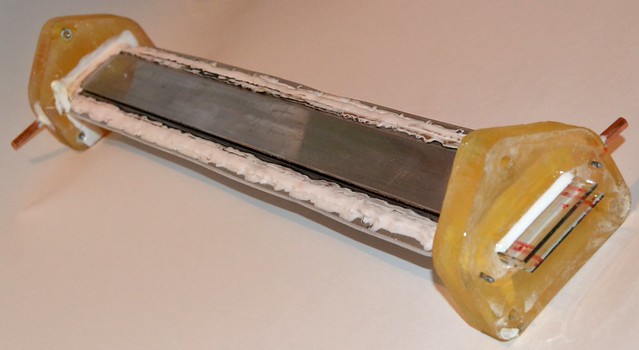

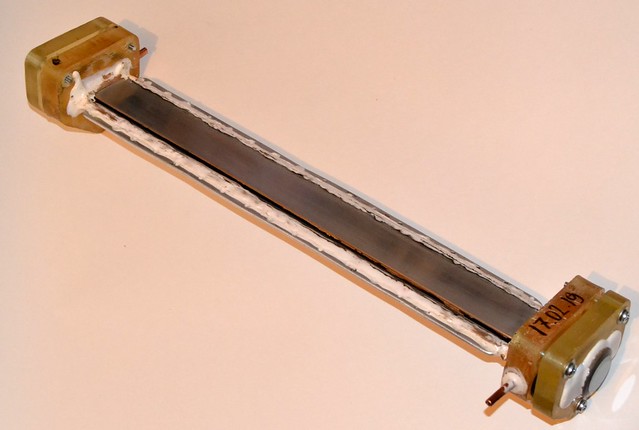

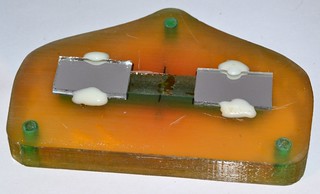

The idea and scheme of the laser cell are more than clear when looking at

the pictures given above. Here we'll stop only on the materials and the

specialties of the assemblage.

The dielectric walls of the cells were made of inorganic (window grade) glass,

2 mm thick. Such a glass is affordable from some frames for photos, or either

it can sometimes be ordered in glass shops. In the latter case it makes things

much easier, because one can also order the appropriate cutting.

The smaller photo frames can contain some 1 mm thick glass, but their size

is less than 200 mm, and if we used such a glass, we'd have to make segmented

walls, hard to be sealed vacuum tight.

The glass walls are 400 mm long (made of photo frame glass 400 x 300). The

width of the glass is determined from the sizes of the electrodes and the value

of the spacing between them.

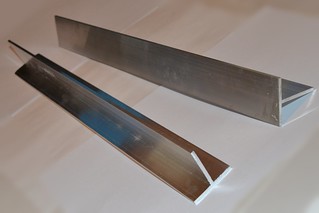

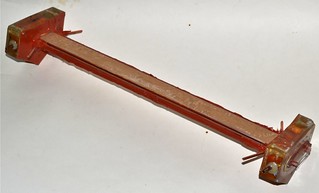

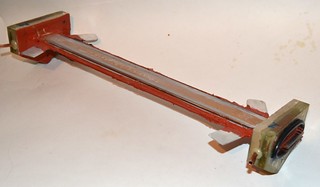

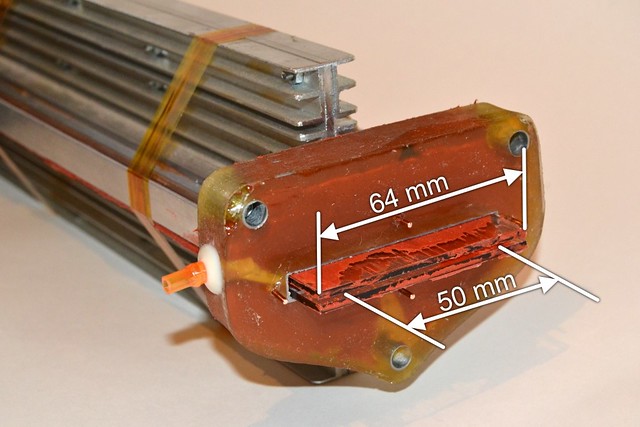

Two different types of electrodes have been made. The first pair of

electrodes is made of T-shaped aluminium extrusion directly. Another pair of

electrodes has more sophisticated design (initially intended to reduce the

total size of the cell). Both types of the electrodes have the thickness of

3 mm. Of course all edges and angles were rounded, and the working surface

was polished. The inter electrode spacing is 30 mm (the aspect ratio of 1:10).

With the sizes of the active area at 3 x 30 x 400 mm with commercial quality

of the gases and assemblage one could hope to get about 80 Watts of output, but

I expect only 8..10 W.

The vacuum cell, having the wall 30 x 50 cm, feels the atmospheric pressure

of 120 kg. It looks like too much for the 2 mm thick glass. Therefore the glass

walls of the cell are supported by some aluminium parts, having been glued

upon the walls. These parts play the role of coolers and at the same time serve

as the electrodes of the external ionization.

The coolers-ionizers are made of rectangular aluminium tubes, 25 x 10 mm

cross sectioned, 380 mm long. The ends of the tubes are sealed off. It is

supposed that at some point they can be filled with cooling water, provided

that the cell could live long enough to achieve the mentioned point of

necessity. The sharp edges and angles are rounded as usual. The coolers-ionizers are glued to the glass walls using a silicone sealant, in the hope

that it will provide some freedom for the parts to move, and thereby, will

reduce the tension, arising due to the different heat expansion of the glass

and aluminium.

The endpieces. Somebody among the great physicists has said: "If the God has

created the volume, the Devil has created the surface." Being applied to our

problems it means that "Devil has created the ends". It is almost easy to seal

off the joint of the electrodes with the glass walls, but You will be very

unhappy with the endpieces.

The cells are meant to be sealed with silicone caulk, and thus one should

choose the material for the endpieces more carefully. The silicone sticks to

the glass well. It is also good for aluminium/ However the endpieces are hard

to be made as a single piece of inorganic glass. And metals are bad choice

too, due to the possibility to shorten the discharge. On the other hand organic

glass, polystyrene, PVC or polyethylene are prone to detach easily when glued

with silicone. Fortunately it was found out that epoxy molds are very

compatible with silicone, so the endpieces were made of epoxy resin.

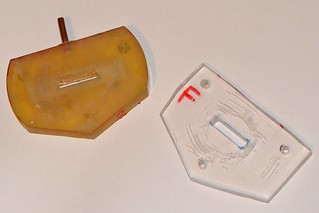

The endpieces and mirror mounts have an unusual shape. It is due to the

specific shape of the laser cell and channel. As it was said above the

endpieces are made of epoxy resin and the mirror mounts are made of organic

glass 10 mm thick.

Finally all this husbandry was glued up into a complete construction.

Interlude 1. Technological. VACUUM TIGHT SEALING.

↑

The "adult" technique knows only three ways of permanent vacuum sealing:

those are welding, soldering and brazing. All types of flanges and rubber

gaskets are apriori considered as leaking and aging. The question is only

at which rate.

Welding brazing and soldering require the device to be assembled in the

glass or metal vessel. The first requires a hardcore glassworking. The second

not only requires machining, but also rises problems with electric strength.

Both variants require some solution to entry the electric current into the

sealed volume. It may be metal-ceramic terminals, glass-metal solds and so on.

All those things are expensive, rare and hard to make at home.

A DIY'er has to rely upon temporary solution an reconcile to some leaking.

In this area the choice is quite wider. One may use glues, plastics, sealants

etc. The most known and widely used ways of sealing are the next three ones:

- Sealing with a hot glue ("glue-gun", low molecular polyethylene)

- Filling with an epoxy resin

- Filling with a silicone caulk.

One can also remind that there also exist sealing of rubber parts with a

rubber glue and sealing metal parts with tin, but those methods are rarely

met in practice.

• Hot glue works best with "fat" plastics: polyethylene, polypropylene, PVC,

etc. The fluoroplastic is a sad exclusion. The hot glue works good also with

metals (aluminium, copper, steel, including the galvanized one). However in

order to get good results with metals one must literally blanch them with

the hot glue, baking it in by some torch or a heat gun. Gluing the inorganic

or organic glasses gives good results too. In case of inorganic glass one

should bake in the hot glue too. Be careful in this case for not to crack

the glass. Gluing of epoxy molds or textolite is also good.

Being a fat hydrocarbon the low molecular polyethylene dissolves grease,

and thus is tolerant to some grease contamination. In the reasonable amounts

of course. Some oil dipped parts are very unlikely to be able to be glued

together.

The hot glue is good for vacuum or low aggressive gases. It can work

underwater. Much worse it endures alcohols and acetone (flakes off in several

weeks or even days). Petrol, kerosene and gear oil do dissolve the hot glue.

(Not instantly, but for a long time operation with these liquids the hot glue

is inappropriate.)

It develops brittleness under the sun rays or even after a long storage.

Due to the appearing fractures the lasers, having been sealed off by the hot

glue, loose the vacuum tightness in two-three years.

In the home conditions the hot glue is exclusively good for sealing. Small

vessels, several cubic centimeters in volume, can be sealed to have leaks less

than 100 torr per year. However it usually requires several attempts.

When heated it is able to self cure the leaks. If the seam does not allow

the hot glue to get into the vessel, one can evacuate the vessel and heat

the seam. In this case the hot glue can self cure small leaks.

• Epoxy resin. Sticks excellently to itself or to materials based on it

(textolites, epoxy plastics). Not able to glue "fat" plastics (polyethylene,

mylar, PVC, etc). Poorly holds the inorganic glass, even if its surface

was grinded. Better, but still poorly, glues the organic glass. The results

with metals depend strongly to the type of the metal being glued and to the

type of the epoxy resin (look at the writings on its box if it is intended

to glue the chosen metal) and to the condition of the surface. Before gluing

the metal surface should be grinded or, better, grooved. Gluing the mirror like

polished metals is the way to fail.

The most special property of the epoxy resin is that it is able (on the contrary to the hot glue or silicone) to stick to zinc selenide parts vacuum tightly. So if You are using selenide mirrors or window_s You may have to use the intermediate parts made of epoxy or textolite. The ZnSe things will then be glued to those intermediate parts by means of epoxy resin and the intermediate parts in their own turn will be glued to the rest of the construction by any other sealant of Your choice.

Epoxy resin is intolerant to grease. In fact most of failures are oftenly

explained as the affect of the contamination. Indeed the grease is the best

excuse for the resin manufacturers. From the practice of glass silvering we

know, that in order to completely degrease the surface one should boil it

for several hours in a concentrated nitric acid. Rare parts are able to

endure that so the excuse works almost always.

Epoxy resin is capable to hold vacuum and gases. Most of the epoxy resins

(excluding the ones, specially intended for wet conditions) are prone to flake

off when used in water or high humidity. Even more fast the flaking takes

place under the action of alcohols. Epoxy resins tend to soften when exposed

to acetone for a long time (several days). This fact can be used to disassemble

the connections, having been glued with epoxy. Epoxy resins are usually durable

to the action of gasoline and mineral oils. However no warranties here.

The connections, having been glued by epoxy resins have exclusively long

lifetime. Most of them continue to work even after 10 years of use. However

the seam is rather brittle. And if it is exposed to thermomechanical loads or

bendings, its lifetime shortens seriously.

My personal experience says that the results of epoxy resins usage for the

tasks of vacuum tight sealings give average results. I've heard about some

commercial He-Ne (or even argon) lasers, where the mirrors were sealed with

epoxy. Evidently they use some very exotic resin or very special gluing

technology. On my memory the best epoxy glued things had leakages of several

torrs a day. It is understandable that there's no sense to speak about years.

The seam is hard, brittle and is not capable for self-curing.

• Silicone caulk. Ideally suitable for gluing inorganic glass. Also suits

good for aluminium. Completely incapable to stick to the "fat" plastics

(polyethylene, mylar, PVC, etc). With other materials it gives unpredictable

(and usually bad) results. For example silicone caulk flakes happily from

organic glasses. Recently I've been able to discover that the adhesion of

silicone to organic glass (and many other materials) can be highly improved

if the organic glass surface was painted by a rhodamine marker before gluing

up. It is still unclear whether the rhodamine itself is responsible for the

phenomenon, or either the surface active additives do that. It also was

found out that silicone sticks well to epoxy molds. However it is still

unclear how long such a connection will live. Silicone caulk (as like as

epoxy resin) completely hates grease. So the surfaces to be connected must

be cleaned thoroughfully.

Silicone is durable to water, vacuum and gases. Longer than other (known to

me) sealants endures alcohols and acetone (however it finally fails too).

Automotive silicones are durable to gasoline and oils.

Silicone seam has usually excellent lifetime. It can keep integrity for

tens of years, A fly in the ointment is that it keeps its integrity all by

itself. Apart from the parts that've been sealed. Silicone is prone to flake

off anything but inorganic glass, With other materials the moment, when it

decides to do it, is unpredictable. Anyways none of my lasers (the ones having

been sealed with silicone) have stayed vacuum tight longer than a year.

In the short time perspective silicone gives an illusion of an ideal thing

for sealing. The vessels, having been sealed with silicone, leak exclusively

slow (it is easy to get less than 1 torr a day). With some experience one

can easily succeed in vacuum tight sealing from the first attempt.

Silicone has a property to self-cure the leaks. It works in the next way:

there is a little hole somewhere, and there is a silicone snot above it.

Certainly when the pressure is lowered the snot is sucked to the hole and

shuts it. Not always this is for good. Because if You shake the laser all

leaks can open once again. And it is double pain to hunt for something

unstable.

Generally silicone is good for the projects of the "make-work-dispose" style.

Only one fact complicates everything: the silicone cures for indecently long

time. Thick seams with restricted air access can cure for several weeks. Even

longer they can contaminate atmosphere in the laser by their fumes.

And finally some general recommendations:

- The number of places for sealing should be as low as possible.

- The seams should be as short as possible.

- The seams should have a simple and closed shape.

Examples:

- A mirror on one of the ends of laser. Or a looking window on its side. The

total length of the seam is small and it has a shape of closed ring. This

sealing is usually easy and produces good results.

- A glued up box having a shape of a rectangular parallelepiped. The total

length of the seams is huge. The corners of the box are the places, where

three seams meat each other - too complicated shape. And also the shape

of the seams is open (one usually can not glue all the box in one action).

As the result this is ne of the most complicated designs to be sealed off.

There's low probability of the success. The leaks are usually situated in

the corners.

- Planar (low inductance) terminals of nitrogen lasers, The seam is long,

but has a simple shape. In some designs it can also be closed. Result:

the terminals are usually easy to seal and provide much less problems than

the endpieces.

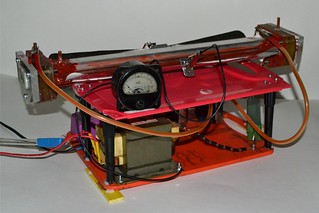

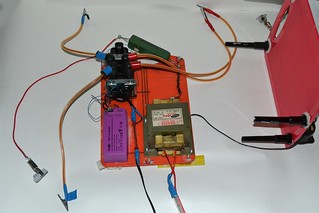

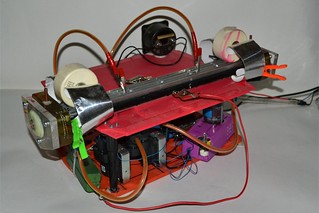

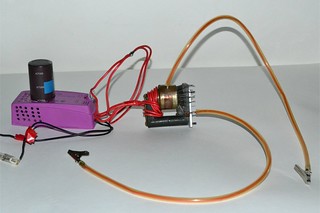

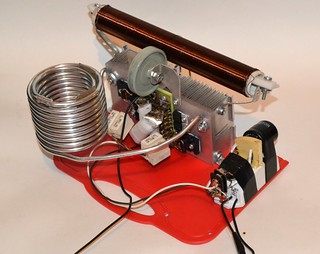

2. Power Supply Unit

The power supply unit is made following the KISS principle ("keep it simple").

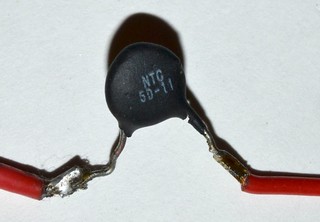

It consists of:

- microwave oven transformer

- electronic transformer for halogen lamps (ye olde Feron 250 W rated)

- two ignition coils with closed core (E - shaped).

- a head from some small milliammeter

- a bunch of diodes for assemblage of a diode stack (note that here's no need

to rectify the voltage from the ignition coils, it is used for ionizing and

should stay alternating)

There was also used a ballast resistor in the "low voltage" feeding circuit.

There are also some kilowatt rated halogen lamps in series with mains cords -

the standard precaution for works with high power devices fed by mains. One can

use fuse here, but it would bother to replace them each time.

WARNING! It should be mentioned that the output ratings of the microwave oven transformer are similar to ones of the electric current used in the electric arm chairs. The only difference is that electric arm chairs use direct current, while here we have an alternating one. However this difference will mean nothing if one touches the output terminals.

REMEMBER! MICROWAVE OVEN TRANSFORMERS ARE LETHAL!

Yes, lethal. And still handy, robust, cheap and affordable when we speak

about a source rated to several kilovolts and several hundreds of milliamperes.

The scheme of connections is the next:

double horned

ignition +-------+

+-------------------+ coil | |

o--------| )| |---o--- |( | laser channel

~ 220 V | Feron )|( 16 | )|( =====

| 250 W )|( turns | )|( +--) (--+

o--------| )| |---o--- |( | ===== |

+-------------------+ | | | |

+--)----+ |

microwave Rb | |

oven 8 x HER308 6k8 | Cp 4 nf |

transformer ---|>|--...--|>|--/\/\/--------+---||----+

4kV peak ||( |

o------- ||( |

)||( |

)||( |

o------- ||( 0..100 mA |

||( / |

------(mA)-------------------------------+

/

The microwave oven transformer has the output of 4 kv peak. (This sample has

the said voltage. Generally I've seen ones giving from 2.8 kv to 4.3 kV.)

A shunt was designed specially for the milliammeter head to make its limit

of measurement to be 100 mA (constant current). The resistance of the shunt

appeared to be 2 Ohms. Here's no smoothing, at least for now, since in 50Hz

pulsed mode we have lower average power and hence can avoid water.

At first there was no Cp capacitors. Those capacitors, connected in parallel

with the laser cell - so called "peak capacitors", or shortly "peakers". Later

it was found, however, that connection of the peakers to the laser cell allows

to rise the top current, at which there's still no arcing (surge current).

Initially the ignition coil was also single. However the tests have shown

a serious deficiency of the ionization. Increasing the ionization voltage was

not acceptable due to breakdowns in the laser cell, so it was decided to reduce

the series resistance of the transformer (ignition coil). The simplest way to

do this is to connect two identical ignition coils in parallel. There were

doubts if the coils would agree to operate in this mode, but the tests were

successful (see below in the results section).

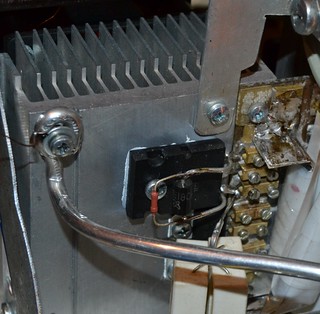

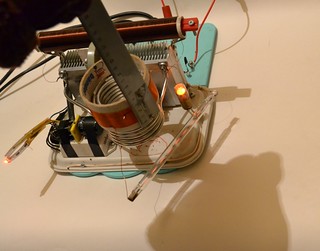

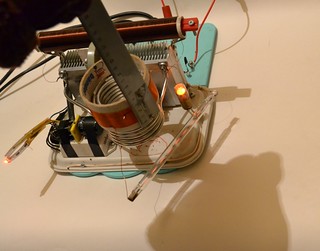

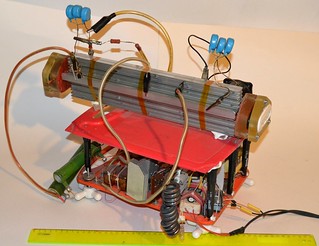

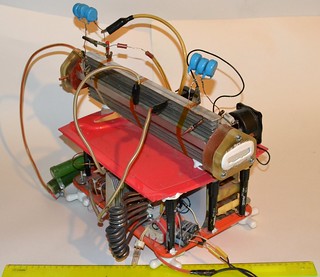

The general view of the power supply unit with and without the top plate

with the laser cell installed are shown below.

Later it was understood that at the design pressures the laser was unable to

reach threshold. And for the lower pressures the voltage of 4 kv microwave oven

transformer is excessive. There could be one rated to 2.8 kv, but who knew it

beforehand? After this the microwave oven transformer was connected not

directly to the mains but through a variac. This provides an ability to finely

tune the voltage and to approach smoothly to the surge current (the limit of

arc formation.)

3. The Results

30.01.2017

The first of the laser cells (the one having foil terminals) was installed

onto the initial variant of the power supply unit (the one with the single

ignition coil, without voltage regulation by variac, and without peaking

capacitors).

The gas discharge in the cell was tested. During the tests the cell was

filled by welding grade argon at different pressures.

- At argon pressures above 2.8"Hg (inches of mercury) and without any

external ionization, the output voltage of the microwave transformer is

just not enough to cause the breakdown in the cell. The current is zero.

- When the external ionizer is on, there appears a current in the "low

voltage" part of the circuit. By gradual decreasing of the pressure and

smooth approaching to the breakdown threshold (2.8"Hg) one can (rather

reliably) achieve currents of two divisions of the milliammeter scale

(10 mA).

- With the increasement of the pressure the current drops rapidly and

it becomes immeasurably small already at 3.5"Hg.

- When reducing the pressure, somewhere between 2.5 and 2.7 inches of s

mercury the current suddenly jumps (up to 25-40 mA) and the discharge

contracts. One can note, however, that here the applied voltage exceeds

the one of the cell breakdown.

- In parallel to the milliammeter (shunt resistance 2 Ohm) an

oscilloscope was attached. The oscillograms show that the current through

the laser cell is formed by series of bell-shaped pulses with their tops

being flattened slightly. The duration of the pulses is 3.5-4.5 ms at the

half height, the repetition frequency is 50 Hz (period of 20 ms). The

amplitude of the current pulses is up to 60 mA, when the milliammeter

shows two divisions.

- Addition of two peaking capacitors (2 pcs of Murata 2 nf x 40 kv doorknob

capacitors, connected with wide stripes to make the inductance low) does not

change anything by itself, but allows to obtain 1.5-2 times greater current.

- In the uniform glow mode (current as measured by milliammeter at 10 mA)

the cell stays almost cool. It means if I was able to get lasing, I could do

it without cooling water.

- The is no success in current increasement. Either we have that we have,

or the discharge drops to arcing. And this is in the inert gas, where the

lifetime of free electrons should be long, and the multiplication ratio should

be top most.

31.01.2017

The cell was equipped with mirrors. The rear one is the rearview automotive

one. Aluminium on glass, concave with 2 m radius. The front mirror is

commercial one, ZnSe coated by dielectric. Plano, 10 mm in diameter. Reflection

is 94% (I have no larger mirrors with such a high reflection).

The cell was filled with mixture CO2:N2:He = 2:3:15 (or either 0.4:0.6:3,

the share of molecular gases was one third).

The first thing that was noted - the drop of current. If one could achieve

average current of 10 mA with argon or argon mixed with 10% of nitrogen, then

here one could get only 5 mA without surging to arcing. (Here I use the term "average" current to designate the current as shown by milliammeter. If

the shape factor was kept unchanged it means only 30 mA of peak current). Need

to say that the helium was taken from a party balloon with unknown storage time

in the shop. The nitrogen was welding grade, but it stood a long storage in

an intermediate vessel (PVC ball). CO2, as usual, was taken from a Crossman's

cartridge, and the quality of these cartridges does not grow year to year.

There were some runs on CO2:N2 = 2:3 mixture. With this mixture there was

no range of operation at all. At higher pressures the current is immeasurable

(less than 1 mA avg) and when trying to lower the pressure it immediately goes

to arcing.

Nevertheless the laser was aligned and got a run. No lasing was observed.

Neither in the mode of low current (I=5 mA avg) nor in the mode with arcing

(I=40 mA avg).

In attempts of increasement of the preionization power the number of turns was

increased in the winding that feeds the ignition coil (inside the Feron

electronic transformer). As the result the voltage caused a breakdown of

silicone near the cell endings. The charred silicone was removed and the

remaining silicone was covered with epoxy.

02.02.2017

Ionization voltage was returned to the previous level. And to increase the

ionization power the second ignition coil was installed in parallel with the

first one. Also the wires (the ones connecting ignition coils with the

ionization electrodes) were replaced. Previously the automotive type high

voltage wires were used. Their drawback is that they are designed specially

to suppress radio interference and thereby can suppress the most useful

part of our ionization current too. At their place just common copper wires

were installed, that should reduce RF losses. Ballast resistor was also

reduced (from 6.8 kOhm to 3.4 kOhm).

Test run with argon:N2 = 1:5 mixture:

- The glow inside the cell became much brighter. And not only the glow

from the ionization source became brighter, but the brightness increasement

given by turning on the main current became much more prominent.

- Average current (the top achievable without dropping to arcing) stayed

unchanged. It was 10 mA and it remains 10 mA. It is especially incomprehensible

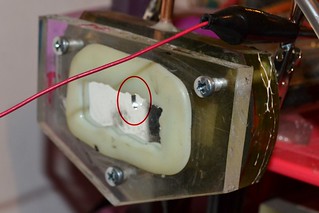

when taking into account the increased glow.

- The corner of the laser cell (silicone sealant between the electrodes

and endpieces) was charred again. After this an attempt was made to clean the

ill place ant to fill it with epoxy. However it is clear that the error is in

the design/ One should leave much greater reserve between the cooling - ionizing

parts and the endpieces. Generally the cell should be redesigned.

- With a variac one can succeed in using the cell at higher vacuum (than

the previous 3 inches of mercury) with corresponding reduction of feeding

voltage. With decreasing of the pressure the allowable current decreases too

but slower than the pressure. At one inch of mercury one could get to

somewhere between 5 mA avg and 10 mA avg without arcing.

06.02.17

The cell with the foil terminals is now dead. the breakdown of the silicone

near the endpieces appeared to be fatal. In attempts to increase current and

drive the cell to lasing its glass wall was overheated and cracked.

The cell with T-shaped terminals (the one with its electrodes being made

directly of T-shaped aluminium extrusion) has agreed to lase. With the mixture

of CO2:N2:He = 2:3:15 havin been mixed 31.01.2017. Resonator is also the same.

Rear mirror is automotive rear view mirror (washed out from the protective

paint), aluminium on glass, concave R=2 m, the front one is ZnSe plano,

dielectric coated, ro = 94%, 10 mm in diameter.

The measured output power was 6 mV by the readings on the homemade Peltier

calorimeter. Calibration of the calorimeter was checked once again but it

constantly gives 6.4 mW/mV. It means the laser gave 38 mW of output.

(Note that the integration spacing was 30 and the 10 mm mirror intercepts

only one third of the laser channel width).

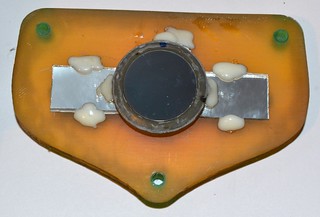

To increase the area of the resonator a hybrid front mirror was made. In a

glass concave mirror (automotive one, R=2 m, aluminium coated) a 10 mm hole

was drilled and then the hole was covered by the mentioned above ZnSe 10 mm

94% mirror. Care was taken to keep alignment between the concave glass part

of the hybrid mirror and its ZnSe part.

With the same gas mixture and with the new mirror the maximum output was

12.5 mV (80 mW), but the result is not directly comparable, because here

the laser was allowed to go deeper into the mode with arcing.

The results of observations (it hardly can be called as "measurements"):

- The pressure optimum is sharp and lies between 1.1 and 1.2 inches of mercury.

At 1 inch and at 1.5 inches the output drops to one half of the optimal one.

At 0.5 inch and below and at 2 inches and above no lasing was attained.

- That lasing threshold is about 10 ma (by the indications of the

milliammeter) and it depends weakly to the pressure (in the range of

pressures, where the lasing was attainable). The threshold of arcing lies

at the same 10 mA when the pressure is optimal. I.e. when completely

without sparks there's no lasing too.

- Going further into the area with arcing gives the optimal output at the

average current of 20 mA. Further addition of current leads only to drop of power.

The arm of the milliammeter here jumps strongly (due to the random arcing)

so the correct readings are impossible. The variac appears to be set to

100..110 V here.

The highest laser output is when the arc is "running" (randomly appears in

different places of the laser channel). When the arc sticks to a certain

place on the electrodes, the laser output drops significantly.

- The cell heats strongly. The tests were made without cooling water, and

in these conditions the coolers become hot to touch (about 40oC) in less

than a minute of operation.

DONT TOUCH ANY PART OF THE LASER UNTIL ALL THE

VOLTAGES ARE TURNED OFF!!!

To the end of the series of the tests something went wrong and the mode of "running arc" became unattainable. The output power of 12 mW became

unattainable too. The arc has stuck to a point on the electrodes and refuses

to leave the place. The top power in this mode was 4.5 mV only (28.8 mW).

07.02.2017

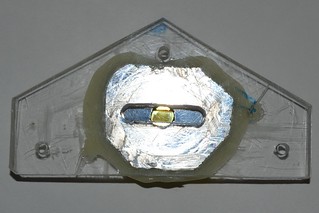

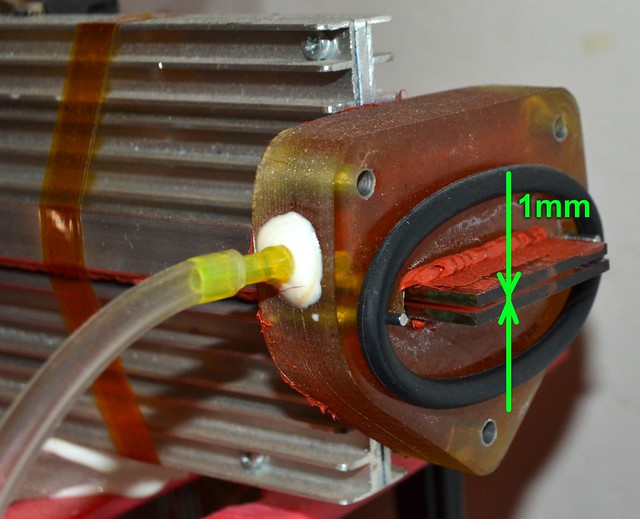

To understand further reading we should discuss the structure of the laser

cells in more details. The schematic section of cells in ASCII graphics is

shown below:

delta

25 mm 2.5 mm

|<>|<------>|<>|

| ________ |

| [________] |

====================

////) (////

====================

| [________] |

| |

| 30 mm |

|<------------>|

For things to be more clear I place here a picture too (however the bad thing

with the picture is that it is stored separately from the text file, and when

You've downloaded the file for the offline reading at the very moment it may

appear to be lost.)

The gap, designated as "delta" on the drawings has appeared here not

accidentally. Its presence or absence affects the discharge shape strongly. In

the pulsed lasers (not actually TEA but similar) the introduction of this gap

allows to suppress sliding discharges along the ionizing electrodes, and thus

to reach the lasing action at pressures up to 250 torr with mixtures of air

with CO2. Without this gap the top pressure, at which the volumetric discharge

still exists in this design in oxygen-containing mixtures, was below 40 torr.

When there was a hope to get a working laser at higher pressures this gap

was excusable. But now, when one can see that the laser can not reach threshold

even at 50 torr this gap may harm, because it leaves an area of non ionized gas

that can cause improper breakdown when under the main voltage.

The gaps were covered with aluminium foil (put it above the glass of course).

The behavior of the system has changed. Previously the top pressure at which

the uniform glow was attainable was 3 inches of mercury, and the attainable

current was almost independent to the pressure and was equal to 10 mA (by

the milliammeter gauge indications). Now the limiting current depends to the

pressure an is equal to (with mixture CO2:N2:He = 2:3:15)

| P |

Imax |

| 0.5"Hg |

5 mA |

| 1.0"Hg |

10 mA |

| 1.4"Hg |

15 mA |

| 1.5"Hg |

10 mA |

| 1.6"Hg |

5 mA |

Above 1.6 inches of mercury there was no success in obtaining the uniform

glow.

Tests for the lasing (resonator is the same as was in the record of 06.02.17):

- The dependence of the output to the pressure has very sharp maximum. When we

approach the top pressure, at which the uniform glow is still obtainable, the

output power grows rapidly. When the arcing appears the power drops by 2-3

times, but the lasing is still present.

- Somewhere a bit below 1.5 inches of mercury (probably 1.45"Hg - I cannot say

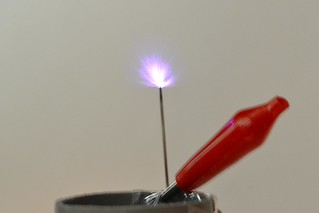

precisely due to the lack of the vacuometer precision) the laser yielded 30 mV

by the indications of the calorimeter (192 mW). When its output is focused

by a lens (F=75 mm) the laser rapidly burns carbon paper and it is able to

ignite a match (even when it is hold by hands - not very firm ones).

09.02.2017

The output mirror (hybrid one) was replaced by another planar ZnSe mirror

having reflectance of 85% and diameter 15 mm. It was installed alone - without any attempt to make another hybrid mirror.

At 1.45 inches of mercury the laser with this mirror is unable to reach the

threshold. The top pressure, where the threshold is attainable is 1.1..1.2"Hg.

The maximal power is 12 mV = 77 mW; the optimal pressure is 0.9..1"Hg.

It is interesting that the dependence of the power to the pressure has lost

its sharpness and its maximum has shifted to the lower pressures. The maximum

is noticeably lower than the limit of the discharge stability.

Then the rear mirror was replaced. A planar glass mirror coated with

aluminium was installed. It is an old (ab)used mirror from a nitrogen laser

that has noticeably darkened due to aging. The resulting laser power has

dropped further on. It became 6..8 mV = 38..51 mW. Optimal pressure became

even lower and the maximum itself became even more soft.

What do the words "optimal pressure became even lower" mean? In fact when

the 94% hybrid mirror was replaced by 85% simple one the laser could not reach

the threshold in the area of stable discharge (15 mA) but still could lase

in the area of the discharge with some arcing (20 mA). With lowering the

pressure one could return the threshold to the area of the stable discharge,

but with the corresponding lowering of the output.

When the front mirror was

replaced too, the threshold raised once again and could not be returned to

the area of stable discharge by any changes of pressure. (Need to notice that

the current border of the stable discharge shifts to lower values with the

reduction of the pressure.) However the one could still move the threshold

into an area, where the discharge contains some arcing (<20 mA). Of course it

caused further drop of the output.

Also need to notice that the border of the discharge stability shifts with

time. It is the lowest at the first turn on of the laser. It is about 10 mA.

After some baking of the electrodes the border moves somewhere to 15 mA,

sometimes it can reach 20 mA. If there appear a bright arc, it burns a spot

on the surface of the electrodes and the border of stability drops to 10 mA

again. Then the cycle repeats. (Here always we speak about the "average"

current as indicated by milliammeter).

Further on an idea to remove peaking capacitors had stroke my head. The

achievable current (without falling to arcing) has decreased strongly (to

about 7 mA) and refuses to rise back. Of course no lasing is here.

I.e. the peakers are essential for the laser operation. It may be due to

they form a relaxation oscillator together with the ballast resistor and

with the laser channel itself. Its frequency should be about 73 kHz, so

the laser channel is actually fed by RF current.

Then an assembly of four K15-4 capacitors (4.7 nF x 12 kV each) was placed

instead of the peaking Murata's. The area of the stable discharge just

disappeared. When using the variac to increase the voltage, initially there

is no discharge at all and then suddenly there appears white spark in the cell.

The spark is fat, strong and has a hearable sound.

Then the K15-4 assembly was removed, and a single Murata (2nF) was placed in.

The area of the stable discharge has reappeared. The lasing was even got there

(4..6 mV) but the things were much worse than with two Murata's.

Then in parallel with the laser electrodes three Murata's were placed

(1/RC = 49 kHz). The power became 21 mV = 134 mW. (One can suppose that if

we return the previous mirrors there will be 400..500 mW, but it usually

does not work in such a way).

The question on the optimal value of the peaking capacitors Cp should be

studied further. It also has a sense to check how the laser will react to the

capacitors of different types. E.g. to the single K15-4. Or to mylar film

rolled K73-13.

13.02.2017

The results with different mirrors.

With the mixture of CO2:N2:He = 2:2:15

- With the front mirror, plano, 85% reflectance; with the rear mirror plano,

aluminium coated glass; and with 3 x 2 nF as the peakers the laser as it was

already written above reaches 21 mV (134 mW)

- With hybrid mirror as the front one (a hole in the center of Al coated glass

concave mirror, enclosed with plano ZnSe 94% mirror); with the back mirror

plano, Al coated glass; and with 3 x 2 nf peaker the laser yields 25 mV

( 160 mW)

- With the hybrid mirror as the front one and with rear mirror concave, Al

coated glass, and with 2 x 2 nf as the peaker the laser yields 30 mV (192 mW).

All concave mirror were spherical with the curvature radius of 2 meters.

Further on (in the resonator having the front hybrid mirror and the rear one

concave) the next gas mixtures were tested:

- CO2:N2 = 1:2

- the highest pressure, at which the lasing was observed 0.6"Hg

- the optimal pressure 0.5"Hg

- the highest current (by milliammeter) achievable without

dropping to arcing: 3 divisions (15 mA)

- threshold current (by milliammeter) a bit less than 3 divisions

(~14 mA)

- top registered output power 6.4 mV (40 mW).

- CO2:N2:Ar = 1:2:6

- the highest pressure, at which the lasing was observed 1.5"Hg

- the optimal pressure 1.3"Hg

- the highest current (by milliammeter) achievable without

dropping to arcing: 4 divisions (20 mA)

- threshold current (by milliammeter) 2.5 divisions (~12.5 mA)

- top registered output power 25 mV (160 mW)

A tiny droplet of xylene was added into the tyre, that contains the

mixture. Gases then were stirred vigorously. As the result the surge

current and the lasing yield became lower (3 divisions and 16 mV

correspondently).

- CO2:N2:Ar = 1:3:6

- the highest pressure, at which the lasing was observed 1.4"Hg

- the optimal pressure 1.4"Hg

- the highest current (by milliammeter) achievable without

dropping to arcing: 3.5 divisions (17.5 mA)

- threshold current (by milliammeter) 2.5 divisions (~12.5 mA)

- top registered output power 37 mV (236 mW)

- CO2:N2:He = 1:2:6

- the highest pressure, at which the lasing was observed 1.5"Hg

- the optimal pressure 1.3"Hg

- the highest current (by milliammeter) achievable without

dropping to arcing: 4 divisions (20 mA)

- threshold current (by milliammeter) 2 divisions (~10 mA)

- top registered output power 25 mV (160 mW)

Hardly comprehendible why increasement of nitrogen to CO2 ratio

has caused output drop when with helium and caused power rise when with

argon. Is it the native properties of the mixtures or just the impurity

of the experiment. (Helium was stored in automotive tyre from the may

of the previous year. By the way, if stored in party balloon it would be lost and dead ten times already. And, judging by the discharge current and

lasing, the tyre did really contain helium after all this time. However

its purity might be low.)

There also were runs (on CO2:N2:Ar = 1:2:6 mixture, after xylene addition)

in gas - static mode. The lasing does probably exist at the first moment

after turning on, but no continuous lasing was observed.

Need to say that all previous runs with lasing were in the slow gas flow

mode (somewhere at 0.1 - 0.3 liter*bar per minute). To achieve this, the

exhaust pipe (the one that goes to the vacuum pump) is clamped slightly.

The gas/vacuum valve on the incoming pipe (the one connecting the laser cell

with the tyre) is to be set to a position that provides the proper pressure

(e.g. at 1.5 inches of mercury column). After this one may turn the ionizer on,

and then turn on the power of the main discharge.

Having read in articles and web-reports how fast do the low pressure

continuous lasers burn out the gas mixture, I have never (until now) tried to

get the lasing in a gas static mode. Ant it is very expectable, that the

first try is fail. (Naturally one could use gas regenerators, special gas

mixture and special materials for the tube, but I had neither desire to do

that, nor the possibilities.)

The web-report genre is rather free and one of its drawbacks is that one

usually needs to read tons of unnecessary info in order to understand what

was meant in one or another place. However need to note that the guides are

best to be read as the entirely whole too. Sometimes somebody, having read

three paragraphs, thinks that he've understood anything and rushes to

production. But no - it does not work. And the one(body) becomes frustrated

and rings all over the mail and internet... And this is when he(she) could

just read the guide a bit further, or a bit more attentively, or a bit more

thoughtfully, or a bit more patiently and get all the answers.

Back from lyrics... Another test run was with CO2:N2:He = 1:2:6 mixture

and another output coupler. This one has diameter 25 mm (ZnSe, dielectric

coated) and reflection of 75% or 50% (The marks on it have disappeared

in the process of epoxy-mounting. Occasionally i will measure its reflectance

and write down here). The laser haven't reached threshold with this mirror

at all.

14.02.2017

Turning On the Brains.

Finally the top power, that have been achieved to the moment, is 236 mW.

With taking into account the fact that the resonator does possibly gather

the light poorly (say one half) and taking into account the duty cycle (suppose

that it was one fifth) we'll get that this laser can give 236 mW x 5 x 2 = 2.36 W in continuous mode.

It have already noted above about the caution to be taken when making

such an estimations. For example considering the light gathering by the

resonator - all affordable mirrors and their combinations have already been

checked (plano-plano, plano-concave, concave-plano, concave-concave/hybrid)

and I already use the best one (concave-concave/hybrid). So here's a little

hope to move forward in this area. Or I should try to install mirrors

directly into the waveguide? The reference waveguide parameter B of the mirror

set up is B = pi*w^2/wavelength, where wavelength = 10.6e-6 m,

w = 0.7*(a/2) = 0.7*1.5e-3 m

- for the planar channel, pi = 3.14...

Substituting the values we get B = 0.326 m. And the condition of low losses

due to modes mismatch, which has the form [3]: h < B/10, where h - is the

distance from the waveguide end to the mirror. We can see that this condition

is fulfilled, because in the current design h is less than 2 cm.

On the other hand we can remember a pocket-sized-lamp-pumped-dye-laser,

where this condition was fulfilled with even more warranty and still the closer

mirrors were to the capillary the better it worked. So in reality here we have

the possibilities unknown...

Coming from the pulsed power to the continuous does promise five times up,

but in reality we can meet gas burning out, or developing of the misalignment

due to overheat. And the promised five can turn out to be three or even two.

Even if we hope for better the estimated two watts with a half sound a bit

small to the wishes of 8-10 W. So I have to research the reasons "why things

go bad" and "how to set it right". Fortunately this laser is a peaceful one in

the contrast to the pulsed (TEA) systems with their tens or hundreds of

kilovolts, tens or hundreds of kiloamperes, their nanoseconds and their

killing electromagnetic pulse. In those systems the measurements are almost

impossible and we have to rely on the theory only. But here we can use all

the arsenal of our measurers and gauges to squeeze the info about what goes

wrong.

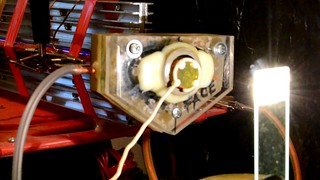

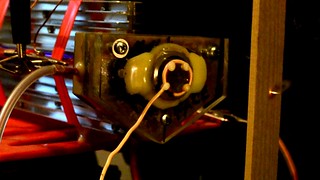

The current and the voltage on the cuvette were measured by an oscilloscope

during the lasing A mixture of CO2:N2:He = 1:2:6 was used. The measurements

were made when the indications of the milliammeter were 3 divisions.

The lasing threshold was 2.5..3 divisions.

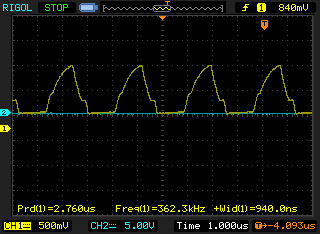

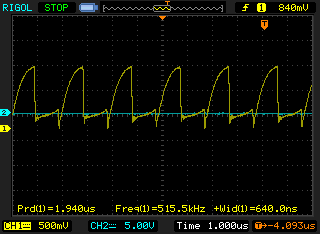

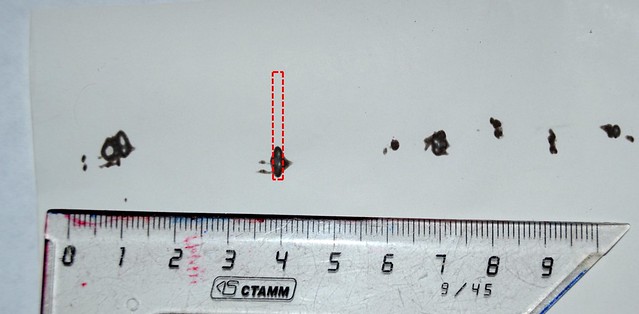

There is the oscilloscope trace of the current through the laser cell (in

the reality the oscilloscope can not measure current directly, naturally this

is the trace of the voltage drop over a shunt having 2 Ohms of the resistance.

It was just the shunt of the milliammeter,) For better visibility I made

the image black-and-white and stressed the trace by a thick black line. You

can take a look at the original image by clicking the picture.

And here is the trace of the voltage (the oscilloscope was connected to the

terminals of the laser cell through an 1:1000 voltage divider):

The voltage is a bit unstable, so the superimposed pulses show that scatter.

The mean line is also stressed by a black thick line. And also one can take a

look at the original by clicking the image.

One can see that the average current at the top of the pulses is 50-55 mA.

The current pulse duration is about 6 ms at its bottom and 2,5 ms at its top.

So the duty cycle is 1/3.3 for the bottom and 1/10 for the top. One can also

get the graduation mark: the measurements were taken at three divisions of the

milliammeter scale, so one division corresponds to ~17 mA of peak current

(providing that the duty cycle remains constant).

The voltage has comparatively short rise (2 ms) flat top (5-7 ms) and long

smooth tail (10..12 ms) due to the remaining charge on the peaking capacitors.

The height of the flat top over the zero level is 1.5 - 1.9 kV.

Interesting to compare the measured voltage with calculations. Vitteman [4] gives the field tension in self-sustained discharge in CO2:N2:He = 1:1:3

mixture being equal to 13 kv/cm at 760 torr. Here we have non self sustained

discharge, but in any case we have to force it as close to self-sustainity

as possible. For 1.5"Hg it will be 13 kV/cm *1.5"/29.9" = 0.65 kV/cm. And the

full voltage drop over 3 cm of the inter electrode spacing will be 1.95 kV.

In comparison with measured 1.7 kV and with taking into account the limited

precision (mostly of the pressure) one can say that the coincidence is

excellent.

Using the obtained data let's try to comprehend what takes places in the

laser (how much of useful energy it has, and how much of it yields the light).

Let the threshold current is 3 divisions (51 mA peak), working current is

4 divisions (68 mA peak). And the useful power is all that is above the

threshold. I.e. the useful power = 1.7 kV*(68-51) mA = 29 W.

On the other hand the period of time, during which the current exceeds

the threshold one (77% level) is 2.5-3 ms. The duty cycle is then one

seventh - one eighth, so the measured 200 mW of lasing correspond to

1400 - 1600 mW in each pulse.

The efficiency = 1.5 W (lasing) / 29 W (useful, electric) = 5.2%.

So the differential efficiency is 5%. It is even more than it was expected

at the start of the project. (Naturally using the best measured values one

can pull its ears up to 8-10%, but I like more reliable values.)

From the estimations above it becomes clear what goes wrong. The power goes

to "the subthreshold". Indeed, if we increase current, say twice, the useful

power will be 1.7 kV*(68*2-51) mA = 144.5 W and the emitted light will be

7.2 W - almost the desired value for the design.

Lets see if the laser will be overheated with this current (136 mA). In the

continuous mode the total power (including the "useless" one) will be:

U*I = 136 mA * 1.7 kV = 231 W. With the heat remover cross section of

0.03 * 0.35 = 0.01 square meters; with the thickness of the laser channel of

a = 3e-3 m and with the heat conductivity lambda = 0.147 W/(m K) the thermal

resistance will be Rt = a/(8*S*lambda) = 0.25 K/W. and the temperature

difference will be deltaT = 231 W * 0.25 K/W = 58 K.

To estimate the temperature difference in the glass wall we should get

that one wall conducts only a half of the total power (i.e. 115 W). Let the

heat conductivity of the glass be 1 W/(m K) and the thickness of the glass

be 2 mm. Here the temperature difference in the glass wall will be:

115 W * 2e-3 m / 0.01 sq.m / 1 W/(m K) = 23 K.

The full temperature difference is 58 + 23 = 81 K and the gas temperature

in the center of the tube : 113 oC. All seems to be right.

For the helium-less mixtures the things are worse. The temperature difference

in the gas will be about 500 K and the gas will certainly be overheated.

The considerations above mean that in order to drive the laser to the desired

power we should (keep) use helium based mixture and rise the feeding current

twice. Sounds easy... Until one remembers that the current is already limited

by the discharge instability... The ghost of the Bealieau scheme has appeared

with its multiple of the resistors by the sides of the laser cell... Is there anything less infernal to make it? The authors of [2] could somehow drive their laser

up to half of an ampere of the supply current and the sizes of their cell were

almost twice smaller.

It is possible that the power supply pulses are bad for the laser and with

going to the constant current the loading characteristics will become softer.

But I am still not ready to suddenly increase the supply power by eight times.

The risk to burn the laser cell is too high. And I still have some questions

to it.

The material of the electrodes may play a bad role. The aluminium oxidizes

easily and it causes strong change in the voltage drop in the discharge near

the electrodes. In its own turn it may provoke arcing.

It is possible that the power of the ionizer is just low. But the most

direct way of its increasement has already met an obstacle in form of limited

electrical strength of the cell. And there is lack of ideas how to increase

the ionization power without making the complicated radio-frequency oscillator.

For now it was decided to build a new laser cell with copper electrodes and

look what it will change.

16.02.2017

While the new laser cell is curing (and it can take as long as two weeks)

some more measurements were taken. I measured the tolerance of the laser to

the mirror misalignment and to the type of peaking capacitors being used.

On the misalignment

To simplify the description lets choose a coordinate system. Let the Z-axis

be directed along the optical axis of the laser (along the laser channel. Let

X axis to lie in the plane of the waveguide and be orthogonal to Z-axis. (The

x-axis is essentially collinear to the direction of the electric current or

either to the direction from one electrode to another). And finally let Y axis

to be directed orthogonal to the waveguide plane.

Here is a picture (hopefully it will clarify the things rather than mess them

up even more):

^ Y

|

========|==================

+--------> X

===========================

Let's remember that in the process of the alignment we direct the alignment

laser beam throughout the resonator of our CO2-laser and observe the spots,

produced by the beams reflected by the front and rear mirrors. Let's call these

spots as "alignment spots."

In the taken coordinate system it was obtained that moving the alignment spot

(related to the front mirror) by 1 cm along the Y-axis (both upwards and

downwards) drives the laser to the threshold with correspondent reduction of

power by 10 times. Even slightly more movement of the front mirror and the

laser can not reach the threshold.

Along the Y axis the threshold corresponds to the alignment

spot motion of

3 cm.

It means that the required tolerance of the alignment is ±10 mrad in the

plane of the waveguide and ±3 mrad in the direction normal to the plane of

the waveguide. (The distance from the alignment laser to the front mirror was

150 cm and we are noting that the beam deflection is twice of the mirror

deflection.)

The resonator was of the stable type. Having both concave mirrors. The rear

one was spherical with R=2m radius; the front one was hybrid one, and the

radius of its spherical part was also 2 m.

The sensitivity to the alignment in the vertical plane appeared to be

unexpectedly high. It makes me think that I need to expand the waveguide a bit.

For example to 4 mm.

On the tolerance to the capacitors type.

In practice capacitors are described not only by their capacity and endurable

voltage. There are at least ESR and ESL parameters:

- ESR - equivalent series (active) resistance;

- ESL - equivalent series inductance.

The ability of the capacitor to heat, when alternating current flows through

it, is determined by its ESR. And the lowest possible discharge time (or the

short circuit current, as You wish) is determined by ESR and ESL both.

Here is some other thing, that should not be related with the current laser,

but to the full extent determines the behaviour of TEA lasers. It is the

dependence of the dielectric permeability of segnetoelectrics to the applied

electrical field. As the result the accumulated electric charge q quits to

depend linearly to the applied voltage U. In other words the law q = C * U

(where C is the capacity of the capacitor) changes its status from the precise

to roughly approximate. It also means that even all three parameters (C, ESR

and ESL) are not enough for the complete description of the behaviour of the

capacitor. E.G. TEA CO2 lasers work best with ceramic doorknob pulsed

capacitors and tend to fail with (seeming to be) low inductance Maxwell ones.

So the theory as well as practice tells us that different capacitors can

lead to different results even in case they have the same capacity. Needless

to say it is interesting to see how the type of the peaking capacitors can

affect the present laser.

The tests were made using the mixture of CO2:N2:He = 1:2:6. The mixture was

aged seriously. The resonator was: rear mirror concave, the front mirror -

the hybrid one.

The initial test (the reference point) was made with using 3 pcs of ceramic

doorknob pulsed capacitors rated to 2 nF x 40 kV each. They were connected

to the laser cell by wide aluminium stripes.

Results:

| Threshold current (as indicated by the gauge) |

2.5 divisions (42 mA peak) |

| Current of drop to arcing |

4 divisions (68 mA peak) |

| Lasing average power |

25 mV (160 mW) |

The peaking capacitors were then replaced by the ones having plastic mold

body insulation and wire terminals. The capacitors were of the ceramic type,

and rated to 40 kV 2 nF. Their capacity was verified by a multimeter. However

even the first glance at them can tell You that they would definitely fail

under the advertised voltage - the gap between the terminals is less than

15 mm. Many of them come with cracks in the ceramic discs with corresponding

degradation of the performance. Their seller named them as "Muratas" but I

refuse to hope that such a serious manufacturer could throw such a bad thing

into the market.

Three of such capacitors were connected in parallel to the laser cell. The

connection was made by copper wire 1 mm in diameter. Subjectively the laser

began to work a bit worse. But the sensation is not verified by figures:

| Threshold current (as indicated by the gauge) |

between 2.5 and 3 divisions (48 mA peak) |

| Current of drop to arcing |

a bit less than 4 divisions

(68 mA peak) |

| Lasing average power |

20 mV (130 mW) |

The results should be taken as "nothing has changed in the limits of errors."

And finally the peakers were replaced by three K73-13 (mylar film, rolled

type) rated to 2 nF x 10 kV. This time even the figures can prove that it

became worse:

| Threshold current (as indicated by the gauge) |

a bit over 3 divisions

(51 mA peak) |

| Current of drop to arcing |

3.5 divisions (60 mA peak) |

| Lasing average power |

16 mV (100 mW) |

After the laser had been returned to its initial state (after connecting

the doorknob Muratas) it gave 24 mV - i.e. the output has returned too.

19.02.2017

An attempt was made to increase the power of the ionizer by means of finer

match of the AC-oscillator (Feron) to its load. In order to do this, different

numbers of turns in the secondary winding (the one feeding the ignition coil)

were tested. In the range from 10 to 20 turns the difference was barely notable.

The limiting current, the threshold and the laser output were essentially the

same. Finally the winding was returned to its original 15 turns.

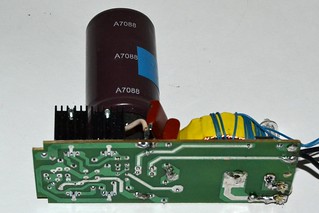

Another thing that was done this weekend was a little upgrade to Feron

electronic transformer, used as the ionizing oscillator here. Namely a 1000 uF x 450 V electrolytic capacitor was attached to the output of the internal diode

bridge inside the Feron unit. So now the ionizer works in continuous mode,

not in the pulsed one. Still testing, and now I can say only that the Feron

unit is still alive but the laser seems to have lost some power.

24.02.2017

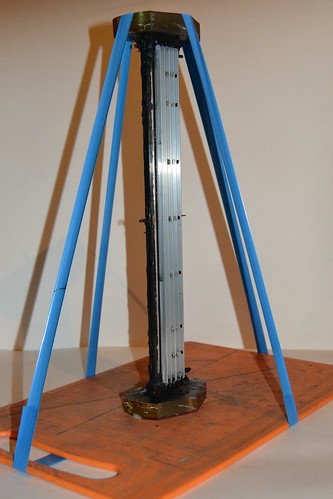

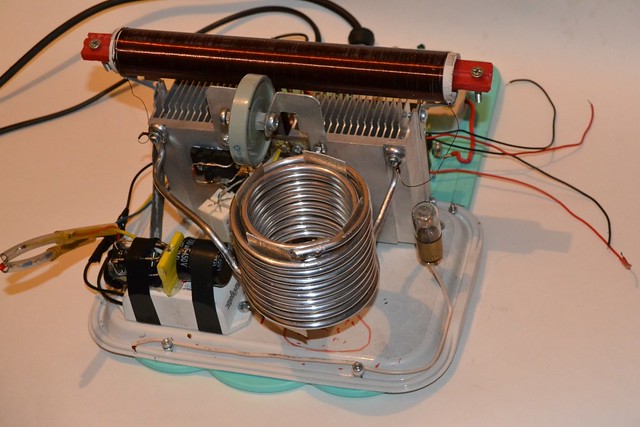

The cell with copper electrodes is now ready. Frankly speaking it should

stand for another week, but lets call it a day.

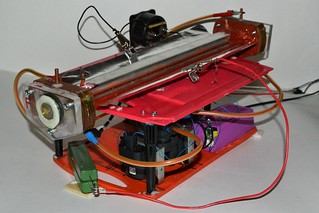

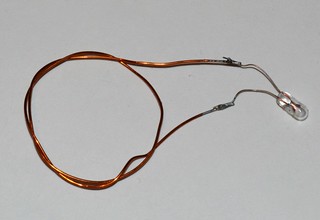

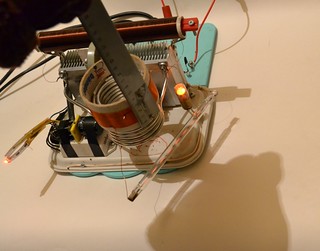

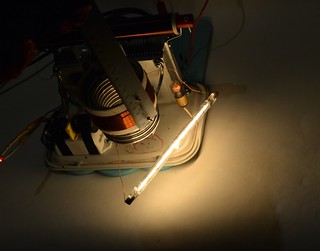

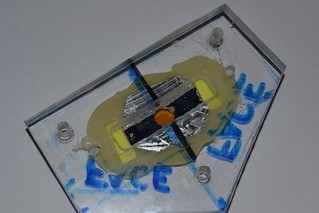

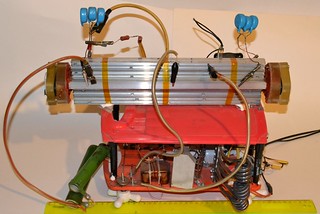

Here's how the laser looks like with the new cell:

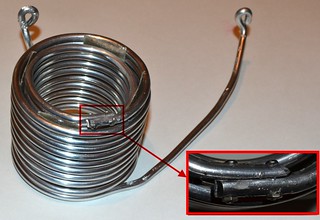

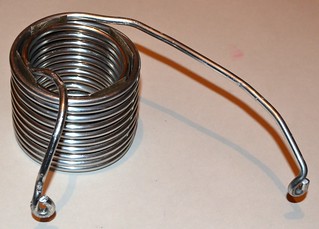

The electrodes are made of copper wire (3mm dia). There were real problems

with its straightening. The most simple way to make it straight is to stretch

it until it breaks. The diameter of the wire after stretching will be slightly

smaller, but this is allowable. Near the very point of the break the diameter

will be considerably smaller, but one can always discard that part.

To pull the 3 mm copper wire until it breaks by hands only is a Herculean

task. And if the piece is long enough (like 10 meters) any jacks and handles

are out of the job too. Finally it was decided to tie the wire to a trailing

hook of one car and pull the wire by another car. It appeared to be unexpectedly

hard to break the wire even by force of car. Fortunately no harm to health and

life was inflicted. I will abstain from describing all the fun here. Lets leave

it for the imagination of Yours.

For the ones, who wants to reproduce the experience, i have only one hint:

You better sand the wire from the oxides before trying to stretch it.

Otherwise You can easily bend so precious straight piece of the wire just by

rubbing it with a sandpaper.

The wire was straightened, and a pair of suitable pieces were cut from it.

After some sharpening and cleaning those pieces became the future electrodes.

They were glued in between two flat glass plates. The sizes of the laser sell

were kept intact: laser channel width 30 mm; waveguide thickness 3 mm; length

of the active part 350 mm; length of the glass walls 400 mm and length mirror-to-mirror 450 mm.

Aside the different material of the electrodes the other difference of the

new cell is that the coolers-ionizers are made not of the hollow rectangular

aluminium tube, but they are made of E-shaped aluminium extrusion. It is

supposed to operate as an air-cooled heat sink. I'm still wanting to avoid

using water as long as possible. Ask why? Remember the written above about the

microwave oven transformer and electric arm-chair.

The new cell was tested on argon containing mixtures: CO2:N2:Ar = 2:3:15 and

CO2:N2:Ar = 1:2:3. It was also tested with some helium containing mixture,

which initially was CO2:N2:He = 2:3:15.

Let me remind, that the cell with the aluminium electrodes almost always

allowed to reach the discharge current of 3 divisions as indicated by

milliammeter, and it was possible to get up to 4 divisions from time to time.

The interesting property is that the top obtainable current depends weakly to

the N2 to CO2 ratio and to the type of the buffer gas being used.

On argon mixtures the cell with copper electrodes appeared to be able to bear

up to 5 divisions of current (as indicated by milliammeter) usually and

up to 6 divisions - occasionally. However the output growth il less

considerable. The threshold has grown up to 4 divisions. It seems like the

main factor of the average current increasement is the increasement of the

pulse duration rather than the increasement of its amplitude. But I've still

not bothered to use the oscilloscope to check it up.

With helium based mixture CO2:N2:He = 2:3:15 the top current, limited by the

arcing, appeared to be the same 3..3.5 divisions as it was with aluminium

electrodes. In this particular case that laser haven't reached threshold. The

helium was (obviously) from a party balloon (newly bought however).

After a proposition that the mixture still lacks helium, it was diluted with

helium twice by volume. I.e. it became something like CO2:N2:He = 2:3:35.

Nevertheless, the current of dropping to arcing was still equal to 3 - 3.5

divisions of milliammeter scale (at pressure of 1.2"Hg). One might note that

with this mixture the laser was able to reach the threshold, but the output

was lamentable.

Carefully (for not to let the air in) into the vessel with the gas mixture a

little droplet of xylene was added. And still the surge current did not change.

But the threshold became unreachable again.

It was supposed that argon may be somehow responsible for higher current on

argon based mixtures. So argon was added to the mixture. The amount of the

addition was ~25% of the total mixture volume. It became then something like

CO2:N2:Ar = 2:3:35:10. And the surge current did again make us happy with its

constantness. There was no lasing too.

Finally, almost by fortune, the mixture was diluted by nitrogen. The amount

of the nitrogen was not measured - a part of the volume that had been expended

in the tests was filled. Kinda like 10 - 20 % of the volume. I.e. it became

CO2:N2:He:Ar = 2:8-13:35:10. (Or if we divide it by two: CO2:N2:He:Ar = 1:4-6:18:5).

After the addition of the nitrogen the mixture has suddenly stopped to behave

bad. The surge current has risen to the values already obtained on the argon

mixtures: 5-6 divisions of milliammeter scale, There appeared lasing. And

not only just appeared... The power has surpassed 240 mW. The mixture with its

almost unknown composition has shown nearly the best result.

Difficult to name the exact value of the optimal CO2 to N2 ratio for this

laser, but it definitely likes plenty of nitrogen.

With the argon based mixture and with this (unknown composition) one a video

was taken, how the laser lights some matches:

With CO2:N2:Ar = 1:2:3 the highest obtained power was 25 mV (160 mW).

With unknown He based mixture the top power was 42 mV (269 mW).

The heat builds up during the laser's operation. The thermal inertia of the

laser cell is just enough for five minutes before the output starts to drop due

the overheat.

28.02.2017

Usage of the copper electrodes has really allowed to increase the limiting

current (achievable before dropping to arcing). But it takes place with "good"

mixtures only and the amount of this increasement didn't even reach 2 times.

With average mixtures the cell with copper electrodes behaves almost like

the one with aluminium ones.

The further point in our checklist is to see whether the discharge

characteristic will become more soft when using the constant current rather

than pulsed one. Let me remind that now the laser is fed by a half-period

rectifier, i.e. by pulses having 50 Hz repetition rate. The ionization

generator has already been prepared for the constant operation (see the record

of 19.02.2017). Lets go further.

Three new diode stacks were soldered up. Each of them contains 8 x HER308

diodes, connected in series. The new stacks plus the old one were assembled

into the full rectifying bridge.

There is still no smoothing capacitor, so

the laser cell is now fed by pulses with 100 Hz repetition rate. (It should

be considered when trying to interpret the values of current indicated by the

milliammeter. Its gear does the time averaging of the acting forces, so

the pulses with the same amplitude but with the doubled repetition rate will

probably lead to doubled indication values. But this is in theory. In practice

it just means that recalibration is needed.)

After the modifications the laser was assembled, aligned and got a run.

With CO2:N2:Ar = 1:2:3 the power has grown to 45 mV (288 mW).

With the helium mixture of the unclear composition (see the record of 24.02)

it reached 70 mV (450 mW).

The power rise with the argon mixture was 1.8 times so far, and with the

helium mixture - 1.7 times. Ideally the output power should be exactly doubled

in both cases. And we got a bit less. But I think that it is too early to

panic, because in range of errors and instabilities it more looks like the

things go right.

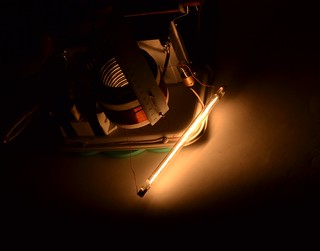

Such a power allows not only to burn up a match. But also to burn through

a sheet of paper. Even a white one. It seems that CO2 laser should ignore

the type of paper - the black one as well as the white one should absorb

10.6 mcm well. But in practice the difference is more similar to the one

we observe when using a neodymium laser - the white paper is much harder to

burn. Here's the video:

There's still no water cooling and the overheat of the laser cell comes less

than in 3 minutes. And if one wants to measure something or to have some fun,

he needs to move his... fingers.. quick to have a time to increase the current

gradually (not letting the arcing to develop) and for the rest stuff.

And finally the output of the rectifying bridge was loaded with a smoothing

capacitor. A microwave oven HV capacitor rated to 0.9 mcf was used. Its value

was intentionally taken lower than needed - it should keep the duty cycle below

100% keeping the heating at the reasonable level.

The result is that with smoothing capacitor laser failed to reach threshold

on argon mixture at any pressures. And on the "good" hellium mixture it barely

reached threshold at optimal pressure. Lemme describe this in more details.

After the smoothing capacitor was connected the limiting current (the one when

the laser drops to arcing) became lower by 1..2 divisions of the