|

Why Un DIY ING? Just because the laser diode is a ready-made commercial grade

device and DIY technologies can only be applied to create a power supply or a

nice looking housing. Or, maybe, for the focusing optics (if it is really

needed there). In fiction the word "undying" means scary creatures with hell

nature. Well, powerfull laser diodes don't frighten anybody, the feeling they

give rise to, is closer to envy. However for the strict developer of homemade

lasers it may be kinda shameful to fall to use of some ready made commercial

laser.

Anyways, the text devoted to usage of laser diodes has finally appeared at

this site. This is not a guide. It looks more like a public domain textbook.

And for this reason it is placed in "technologies" department.

I need to warn: this text is intended for the "saber-builders" - those ones,

who thinks, that a thing may be called as "laser" only when it is able to burn

and cut with its ray of light. Thus the problems of low power laser diodes

(weaker than 1 Wt) are not discussed here. The specific problems, like width

of spectrum or wavelength stability are omitted too.

Contents

- POWER SUPPLIES FOR LASER DIODES

- SIMPLE ANALOG CURRENT REGULATORS

Simple circuits of analog constant current sources are presented. These

circuits are best for driving of laser diodes. The circuits can be

built successfully by a technician of amateur level.

- PULSED CIRCUITS

Schematic of pulsed mode power supplies are (to be) presented. These

are SMPS current regulators, voltage regulators and hybrid circuits.

WARNING: to build and debug these circuits one may need the abilities

of specialist in electronics of higher than average level.

- LASER DIODES AND THEIR PARAMETERS

The meanings of the main parameters of laser diodes are explained. There

is also a list of recommendations for proper choice of laser diode for

buying.

- THE OPTICS

Basic knowledge of geometrical optics is reminded. The meaning of main

terms is described. The typical optical schemes of most importance for

lasers are discussed. Simple formulas for calculations are provided.

There are also examples of calculations.

- METHODS OF POWER INCREASEMENT BY ADDING MORE LASER BEAMS TOGETHER

- GEOMETRICAL ADDITION

There described how to make a beam combining system of a popular "knife-edge" type without using professional equipment. An example

is given of gathering the light from four laser diodes into practically

single beam having the total power of 16 Wt.

- POLARIZATION ADDITION

A method of combining two laser beams with different polarization into

one beam is described.

- SPECTRAL (COLOR) ADDITION

A method of combining many laser beams with different colors into one

beam is described.

It appears that the title of this text tunes to the mood of mystics and

religion. So here are some dogmata being in use among the people having deal

with laser diodes. How to apprehend them and how to treat - one can read this

inside the text.

Power supplies for laser diodes

↑

On the power supply: It is relatively wide known already that one must feed

the laser diodes using so called "constant current source" and not by a voltage

regulator. The simplest are the analogue regulators. Here is a pair of good

circuits.

Circuit N1

↑

The circuit is based upon one chip voltage regulator being connected as a

constant current source:

____________

/ O \

| |

--------------

| KPEH22A |

| LT1083-CT |

| |

|Adj Out In |

-+----+-----+-

| | |

| +--+ |

| | | SW1 6 Amp

R2..R5 +-/\/\/-+ | /

1.0 Ohm | | +---------+----+ +------+

each +-/\/\/-+ | | |

| | | | 2 x 18650 |

+-/\/\/-+ | | Li-Ion |

| | | | cells -----

5W +----->>--+-----------+-------+-/\/\/-+ | | ===

808 nm | | | C1 | C2 | R6 -----

_+_ / R1 | >400uF | >400 uF / 10 kOhm ===

Laser \ / \ 10 kOhm --- LOW ESR --- \ |

Diode -+- / --- --- / |

| | | | | |

+----->>--+-----------+------------------+---------+--------------+

Resistors R1 and R6 are only to discharge electrolytic caps C1 and C2 safely.

The voltage here is always not higher than 10 volt, so the word "safely" does

not mean any danger to Your health or life. On the contrary the charge of C1

and C2 is VERY dangerous for the life of the laser diode. In case of any random

contact it can easily kill the precious device.

C2 capacitor serves for prevention of SW1 switch ringing.

C1 capacitor is of the very importance here. Calculations in LTSpice and

modeling on real circuits does show that there exist a positive and non-zero

value of the capacity of this capacitor, below which the circuit refuses to

operate - it produces an over-regulating overshot current and kills the diode.

This threshold capacity is individual and depends to the voltage regulator

chip parameters as well as to the current setting. For most chips like LT1083

it is about 100-200 mcf. For LM317's this value is lower. So if we chose it

to be C1>400mcf we should have enough of safety margin.

Resistors R2..R5 are current measuring/current setting ones. Generally the

principle of operation is just to force the on-chip voltage regulator to set

the constant voltage across the fixed resistor. Since the voltage is constant

and the resistance is constant, the Ohm's law will unavoidably set the current

to be constant too. The resistor is composed from many ones. There are three

good reasons to do so:

- They dissipate high power;

- The errors of their resistance will partially compensate each other;

- By varying of the number of soldered resistors one can vary the value of the

current, being produced by the circuit. (And thus to set the power of the

laser.)

Avoid to use a potentiometer here! It is a proven way to kill the laser diode.

Avoid switches too. One can vary the number of the resistors by soldering only.

In the worst case You can use computer jumpers. But only if You are sure that

they are reliable enough.

Bonuses of the circuit:

This circuit is VERY simple and uses VERY affordable parts. Along with this

it has a high precision and many of internal protections of any kind: from

shortcircuit, from overheat, from overvoltage of the power supply and so on...

Maluses of the circuit:

Despite the comprehensive set of protections the circuit is NOT protected

from the reverse polarity. So be extremely attentive when installing the

batteries.

Another issue is that this circuit hates a bad connection between it and the

laser diode. Indeed, when the connection is bad the constant current generator

tries to rise the current and charges the C1 cap. And when the connection

recovers, all the charge from C1 flows through the diode and kills it.

This drawback is more or less the property of any constant current type

regulator. Use reliable wires and soldering. One should never try any kind of "poking" of the leads of the laser.

The circuit is brakish enough. The typical rise and off time is well above one

millisecond, and it is determined by charging the C1 and C2 caps. However

remember that those caps are chosen exactly due to the properties of the chip

itself. So we can say that the circuit is slow due to the fact that those

voltage regulators are too slow themselves.

Another issue is that the circuit behaves badly under the dynamic changes of

load. It is very expectable - there is no limits for the current to flow

between the large capacity C1 and the laser diode. With powerful gallium

arsenide diodes (red and infrared ones) there is nothing bad here, but with

gallium nitride ones (blue and green) it may cause failures. The last ones

behave like they have an area of negative differential resistance, like tunnel

diodes.

One should also keep in mind that some of the on-chip voltage regulators

are fake ones. When buying those LT1083, LM196, LM338 etc one can easily

face something very wrong under the good looking outfit. So ALWAYS CHECK

THE CORRECT OPERATION OF THE NEWLY ASSEMBLED CIRCUIT BEFORE CONNECTING

LASER DIODE TO IT!

Tho check it out it is better to load it by different resistors and to look

how the current depends to the load. Hint: if the circuit works correctly the

current should remain almost constant with any reasonable variations of load

(say between zero/shortcircuit and one Ohm).

If one has an oscilloscope it is very desirable to check the rise and fall

curves occurring during turning the circuit on and off.

Generally the impression is very positive from this circuit.

For better safety one should add a diode between the battery and the circuit -

it would protect from the reverse polarity, and add a small resistor in series

with the laser diode (like 0.5-1 Ohm) - it will make it more stable under the

dynamic changes of load. However these improvements cause high overhead in the

required size of the battery. Consider 1 additional volt across the protective

diode and one or two volts across the stabilizing resistor.

The efficiency of the circuit grows with rising the voltage drop on the diode.

So using this circuit to feed a blue diode (4.3 V) or to feed two IR diodes

in series (4.8 V) one can expect the efficiency as high as 50%.

This circuit has:

- Powered two portable 5W lasers for reasonably long time without a fail;

- Burned out one red diode from DVD drive - a try to control current by

a variable resistor;

- Burned out one blue diode. It is when it was found out that with this circuit

and the blue ones, one should not exceed a half of the current rating of the

diode being used.

Return to contents Return to contents

Circuit N2

↑

Two transistors as constant current generator.

There are several variations based on the same idea:

NPN + MOSFET:

/

+--+ +---|>|-------+---------------------+

| SW1 10A10 | |

| | |

| \ R1 |

| / 100 Ohm irf3205 |

| \ |-+Drain

| / Gate||

| |__________________J|-+

| | | |-+Source

| |Collector | |

| 2 cells \ | |

| Li-Ion 2n2222 \|Base | |

| 18650 /|----------)-------+

| / | |

----- |Emitter R2 \ \ R3

=== | 10k / / 0.14 Ohm

| | \ \

| | / /

----- | | |

=== +-------------+-------+

| |

| +-----+------+ 5W

| | C1 | | 808 nm

| R4 \ 10u| | Laser

| 10k / --- _+_

| \ --- \ /

| / | -+-

| | | |

+----------------------------+-----+------+

NPN + NPN:

/

+---+ +---|>|-------+---------------------+

| SW1 10A10 | |

| \ TIP41C |

| / R1 2N3055 |

| \ 100 Ohm kt819 |

| / |

| | |/ Collector

| +-------------+-----|

| | | Base|\

| |Collector | |Emitter

| 2 cells \ | |

| Li-Ion 2n2222 \|Base | |

| 18650 |----------)-------+

| /| | |

----- /Emitter R2 \ \ R3

=== | 10k / /

| | \ \

| | / /

----- | | |

=== +-------------+-------+

| |

| +-----+------+

| | C1 | |

| R4 \ 10u| | Laser

| 10k / --- _+_

| \ --- \ /

| / | -+-

| | | |

+----------------------------+-----+------+

One could imagine a MOSFET+MOSFET here, but due to (comparatively) high voltage

needed to turn a MOSFET on the voltage drop over the current-measuring resistor

R3 would be 2.5-3 volts even for the so called "logical driven" MOSFETs. And

it is quite an overhead.

In the NPN+NPN variant the circuit was tested with a 5W 808 nm diode, The kt819

transistor appeared to be tough enough, so three channels in parallel were used.

A "heavy-caliber" laser pointer worked flawlessly until the attempt to use

a commercial constant current driver there. That diode was burned out, but the

described driver has nothing to do with that.

Another variant was specially intended for use with batteries:

/

+--+ +--+--|>|-----+---------------------+-----+

| SW1 | 10A10 | | |

| | + C3 | | 5W

| --- C1 / SW2 3.3n --- _+_ 808 nm

| --- >100uF + --- \ / laser

| | | | -+-

----- | \ | |

=== | / +-----+

|18650 | \ R1 |

|2 cells | / 100 Ohm irl540 |

|Li-Ion | | |-+Drain

----- | +------+ Gate||

=== | | |__________________J|-+

| | | | | |-+Source

| | | |Collector | |

| | | \ | |

| | | 2n2222 \|Base | |

| | | /|----------)-------+

| | | / | |

| | --- |Emitter R2 \ \ R3

| | --- C2 | 10k / / 0.14 Ohm

| | | 0.2 | \ \

| | | uF | / /

| | | | | |

+--------+---+------+-------------+-------+

In previous variants the diode was connected in series with the current

regulator. It is correct, since the constant current generator makes the

current to be constant in anything connected in series with it.

As one can see in the last scheme the diode is included into the drain

circuit of the mOSFET. This allows to avoid the subtraction of the voltage

drop on the diode from the total power supply voltage. So the full supply

voltage is available to control the gate of the MOSFET.

The drawback of this connection is that the laser diode is under a voltage

in relation to the common wire (to the ground wire). Sudden shortcircuit

to the ground - and the diode is dead. Nevertheless in battery powered

circuits the term "ground" is rather conditional one, and we can utilize

such a connection if not planning to feed the device from the mains.

If one uses a logic level MOSFET (like irl540 or irlr2905), if the laser

diode is red or infrared and if the reverse polarity protection diode is

excluded (shorted), the scheme becomes able to operate from a single Li-Ion

battery (3.7V). It is cheaper, occupies less size and also there is much

less of heat on the transistor. The price is however is the danger to kill

the diode by inserting the battery in reverse.

In all variants of the circuit there is a sense to compose the R3 resistor

from several discrete ones. The necessary value of the constant current can

be selected by soldering the necessary amount of the resistors. It is clear

that until the proper current value has been set, one should never connect

a real diode as the load. Use a 0.5-1 Ohm resistor there or a pair of

powerful rectifier diodes in series there.

C1 capacitor is the protection from the SW1 switch ringing. The ringing

of SW2 affects performance much less, because SW2 conducts only a small

current, limited by R1. Also the soft turning on (provided by slow

charging of C2 through R1) is the very mean to lessen the harmful influence

of the switch ringing.

THE MALUCE OF THE CIRCUIT is there is a lack of reference voltage. In

practice it means that any newly assembled circuit needs individual tuning

by variation of R3 value. There is no compensation of the temperature drift

also. Besides for the independent reasons You don't want to turn on this

driver when it is too cold (winter) or too hot. In the first case there is a

danger to kill the diode due to the humidity condensation. In the second case

there is a danger to kill the power MOSFET and/or the laser diode due to the

overheat, since the circuit has no means of the overheat protection.

THE BONUSES OF THE CIRCUIT are:

- The possibility to operate using a single Li-Ion battery (when using some

logic level MOSFET and without the reverse polarity protection diode);

- Excellent damping of transient current under the dynamic load variations

due to the absence of a large capacitor in parallel to the laser diode.

Usually this scheme leads to comparatively large size of driver. Mostly

it is due to the large heat-sink of the power MOSFET. If (as it often happens)

the efficiency is factor of no importance for You, and You are bothered only

by the MOSFET overheat, the circuit may be made much smaller just by moving

the heat dissipation place from the MOSFET to some resistor. Simply add a

resistor in series with Your laser diode. The exact value of the resistor

should be verified by trials and errors at some large sized model of the

circuit with a heavy heat-sink. This value depends on the voltage of Your

battery and the desired current. (For feeding powerfull diodes from a pair

of Li-Ion battery the necessary resistance is usually about 1 Ohm). The

added resistor reduces the voltage drop across the powerful MOSFET and hence

makes its life easier. On the other side, most resistors can operate safely

at temperatures of the order of ~200 degrees of Celcium, and thus do not

require any additional heat sink.

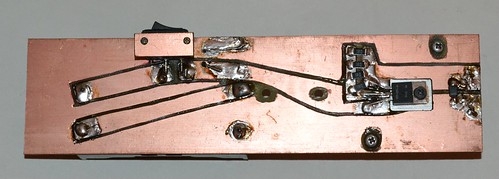

On the photos below an example of miniature two-transistor current regulator

is shown. It has additional resistor for the MOSFET relief. The driver is

intended for use inside a standard laser pointer housing.

Both circuits are simple enough and if there are no soldering errors they

begin to operate properly right after having been assembled. The only tuning

is to chose the correct value of the current measuring / current setting

resistor (R2-R5 in the circuit with on-chip voltage regulator and R3 in the

circuit based on two transistors). In order to do it, solder a dummy load

to the output terminals of the circuit (in place of the laser diode) and

adjust the value of the current setting resistor until the desired current

is obtained. In the simplest case one can use a resistor (0.5-1.0 Ohm rated)

as the dummy load.

The current through the load may be measured in several different ways:

- If a simple resistor is used as the load one can simply measure the voltage

drop on it using some multimeter, The value of the current can be readily

obtained by applying the Ohm's law.

- One may connect a multimeter in series with the load. The multimeter should

be switched to ammeter mode in this case. For these measurements I advise

to make an additional set of probes for the multimeters. The proper probes

should be short enough (not longer than 10 cm) and made of thick wire.

- One can attach an additional current-measuring resistor in series with

the load and measure the voltage drop on it. This method is especially useful

when measurements are made by an oscilloscope.

- And finally one can measure the voltage drop over the current setting

resistor. However two conditions are to be met here:

First: the value of the current setting resistor must be known precisely.

It is easy if the one is formed by a number of commercial resistors. And

it is almost impossible if You are using a piece of wire there and adjusting

the length of the wire until the necessary load current is obtained.

Second: the stay currents there are to be negligible in comparison with the

main load current.

The stray currents are: the ADJ lead current in the circuit

with on-chip voltage regulator or the base current of the control transistor

in the circuit based on two transistors. This is easy if the diode to be

used is powerful and the full load current has the value of several Amps,

and this is not so easy when trying to drive diodes of low or medium power.

Sometimes the two-transistors driver shows a tendency to oscillate at high

frequency (like ~30 MHz). Sometimes it takes place only in moments of switching

on/off. In other cases it can show permanent oscillations. In case of permanent

oscillations it is easy to diagnose them with a multimeter. If the circuit gives

too low current (in comparison with the expected value) and if there are no

soldering errors, it means the HF excitation. The temporary HF bursts during

switching on and of can only be seen using an oscilloscope.

If the HF excitation takes place one can try to jam it by including some

50 Ohm resistor between the base of the control transistor (2n2222) and the

point of signal taking from the current measuring resistor R3. One may also

use ferrite beads, since the main purpose of their design is to dampen the HF

oscillations. One can also try to replace the control transistor (2n2222) with

another one, having lower frequency border. The russian kt3102 works good

here. I am sorry, but due to the lack of testing, I can not recommend some

good transistor from the international nomenclature.

And finally the most correct and effective way to jam the RF oscillations is

to reorder the printed circuit board geometry.

When You have tuned the scheme, You need to check whether it really does

regulate the current or not. In order to do this measure the current several

times, each time attaching different resistor as a load. The current should

stay reasonably constant. (For the two-transistor circuit the changes of

current in range of 5-10% are acceptable.)

One need to keep in mind that both schemes require that the voltage drop

over the load should be less than the supply voltage minus the voltage drop

over the current-setting resistor and minus some additional voltage drop

of the regulator element (~1V for the on-chip regulator and bipolar transistors

and equal to the voltage drop over the open channel resistance for MOSFETs)

In other words You can not choose too high value of the load resistor.

On the contrary You can freely choose the value of the load resistor to be

as low as zero. Since the circuit regulates the current it wont affect much

its safety or performance. Nevertheless If You measure the current by the

voltage drop over the load resistor get ready to face huge measurement errors

id using too small resistance there.

If You have an oscilloscope (and if You are going to make some laser diode

drivers You definitely ought to get one) then BEFORE ATTACHING THE REAL LASER

DIODE TO THE OUTPUT OF THE SCHEME check the absence of current overshots when

switching the circuit on and off. For the two-transistor scheme it is good to

check for the absence of current overshots during dynamic load changes. To do

this make the dummy load using the next schematics:

o--------------------+-----+

| |

| +

| / SW

| +

| |

/ /

\R1 \ R2

/ /

| |

o----+---/\/\/---+---+-----+

| R3 |

^ ^

A B

Where R1 and R2 have the value of the order of the laser diode resistance at

its working mode. (For example for a five watt rated infrared diode:

R1 = R2 = 2.4V / 5A = 0.48 Ohm ). The R3 resistor should have its value as large

as R1/10...R1/5.

The oscilloscope's probe is to be connected in parallel to the R3 (points A and

B on the scheme). When turning the SW switch on and off there should be no

noticeable overshots and ringing.

Generally the powerful laser diodes are the devices heavily overstressed

in several parameters (Like the electrical and optical power density, electric

field tension and so on) so they die by every sneeze. And they cost damned high

and to loose one is a tragedy and funeral. So to use the laser diodes is less

science than a mysticism and religion. The science is based on observational

facts and argumentation. The religion is based on dogmata.

DOGMA THE FIRST - DOGMA OF LASER DIODE INFALLIBILITY.

It can be expressed as that: IF THE LASER DIODE HAS DIED ITS POWE SUPPLY IS

GUILTY.

There are other dogmata too, but lets stop here for a time.

It is considered that even the smallest surpass over the allowed limits,

even for the shortest time is strictly forbidden. For example a datasheet of

5 watt rated infrared diode says that the maximum current is 5 amps. One

should get is "YOU are not allowed to overshot it even by 1 mA even for 1 ns"

Moreover it is considered that the reverse polarity is strictly forbidden.

Even for 1 mV over 1 ns. It means You can kill the laser diode by Your

multimeter in an attempt to find its correct polarity. (In practice I don't

remember any case of killing a laser diode by a multimeter, but it is HERESY

to doubt in dogma)

Even worse that it is considered that one must never exceed the maximum

allowed output power. (Even by one milliwatt during one nanosecond). Why I say "worse"? Because in general the watt-ampere characteristic of the diode (in

other words its efficiency) depends at least to its temperature. And You

can easily exceed the top allowed power even when keeping the supply current

in the allowed limits. Just by using it outdoors in cold weather. It is

considered that a proper driver should contain an optical feedback to keep

the output power in its limits. For the further details I'd better send You

to Sam'S Laser FAQ, because we wont apply all those features here. Otherwise

our simple LD driver will blossom with hundreds of protections and thousands

of sensors, and it will grow a data center nearby to process the data from all

the censors and to elaborate a strategically weighted solution on its base.

Dogma of the diode infallibility leads to two things in our case:

| First: |

If Your don't want to shed the tears on the prematurely passed away

laser diodes (our precious), there is no such words as "forgot" or "was lazy" to You:

"Forgot to check the current"

"Forgot to check

for overshots"

"Too lazy to check, I've build a thousands of such

drivers, what can go wrong?" |

| Second: |

When You know that the smallest excess of parameters is strictly

forbidden, and when You know that any real device (including Your

driver) has some spread of parameters, the obvious conclusion is

that You must "derate" (or "downrate") the device. It means You

must provide a sufficient difference between the value of the

current You driver supplies and the value of the top allowed current.

That safety margin must be large enough to keep the current, power

and any other parameters in their safe limits in any case. (In case

of any variations of the supply voltage, of the ambient temperature,

etc.) |

Performing deratization, sorry, derating of the diode You are being between

two sides: on one hand You don't want to put too much power to avoid killing the

diode and on the other hand You don't want to pot too low power - or else

would not it be simpler to buy a 10 mW green pointer in the nearest stall?

It is understandable that if one does not exceed a half of the top allowed

current (e.g. 2.5 amps for that 5W rated infrared diode, having been used as

example many times above) it almost warrants the safety of the diode, but the

output power won't be acceptable.

Blessed the one, having a bunch of laser diodes, and having the opportunity

to kill a few of them to estimate the borders of the allowed. Others are usually

in lack of such possibilities.

Sometimes the manufacturer suggests the optimal (to his opinion) amount of

derating. For example Nichia NUBM08 diodes are strongly recommended to be fed

by a current not exceeding 3 amps. At the same time the table of absolute

maximum rating in its datasheet contains the value of 3.5 amps. Most other

manufacturers lack such a respect to the clients.

The real value of the current You decide to set depends:

- To Your assurance in the driver's reliability.

The lower is the precision of the current regulation, the larger safety

margin You will choose.

- To Your assurance in the laser diode reliability.

The diodes of top rated manufacturers (such as nLight, Osram) have a good

probability to operate flawlessly at the current of 95-99% of the top

allowed one. "Noname" diodes should be fed by the current that corresponds

to 60%-80% of the top allowed output power. (If You have no power meter -

set the current to 60%-80% of the top allowed current for this diode.)

- To Your prosperity.

Indeed if You can bear easily the death of a few laser diodes, You can

drive the diode to the maximal allowed current (or even higher) without

the excess of care. And for You it may be worth to burn out every other

laser diode only to boast the "most powerful laser pen in the world"

- And finally it depends to Your bravery/insolence.

If You feel being the gambler, I recommend to set the current to 110%-120% of its maximum allowed limit. In case of success You will become

the owner of the "most powerful in the world, etc, et..." In case of

fail - just consider it wasn't Your day.

In any case I would not recommend to exceed 150% of the maximum allowed

limit even to the most hardcore gamblers.

There exist another one interesting circuit for current regulation. It

has the name "current mirror":

Its principle of operation is that a transistor (either field one or bipolar

one), when being at linear part of its working characteristic, can itself work

as a source of current (means current regulator). One needs only to adjust a

bias on its base(gate). The required accuracy of this adjustment is high so

it cannot be made manually. The left part of the circuit is essentially the

authomated generator of this bias for the right part. Due to the base of the

left transistor is directly connected with its collector, the bias on the base

authomatically settles at the level, that provides the current, that flows in

the left part. This current can be set by R1 resistor. Note that this current

is not exactly equal to V1/R1, because the voltage drop over transistor Q2

can not be zero. In practice one could measure the collector current of Q2

(or measure voltage drop over R1) and adjust the R1 value so that the current

has the desired value.

After this the bias on the base of Q1 transistor becomes the same as it is

for Q2 transistor, and if the transistors are identical, their collector

current will be identical too: I(Rload)=I(R1) for any loads that obey Rload<R1.

They say that the right side of the circuit "reflects" the current of the left

side. This is the reason for the name "current mirror".

If things were limited only by that the circuit would be of zero importance

for laser diodes feeding. Indeed, who wants to waste, say three amps of current

in the left shoulder of the circuit, for only to get the same three amps in the

right shoulder? However the things aren't so bad in reality. Just try to

install a low power transistor into the setting shoulder of the circuit and

a high power one into the regulating shoulder. This approach works not only

with bipolar transistors, but with MOSFETs as well:

In this case it will appear that the current in the shoulder with the load is

higher than one in the shoulder with the current setting resistor. I.e. waste

of energy of the energy source became lower and the efficiency of the circuit

has grown up. One can say that it is a "curved current mirror".

Now about the shortcomings:

One can understand easily that if the voltage of feeding source becomes

higher the current in the current-setting shoulder will rise up. The current

in the forcefull shoulder will rise also. It does not mean the surge of current

regulation. It just means that the circuit is stabilized in relation to the

load, not in relation to the feeding source. On the contrary the previous

circuit of the responds

not only to load change but to feeding voltage change too.

However the fact that the circuit responds only to changes of load is not

very serious drawback. In stationary circuits one can easily provide regulation

of feeding voltage, while in portable things the voltage of batterries is

usually known well, and if the driver does not exceed the maximal allowed

current of laser diode with fresh batterries, there will be no excess at any

stage of discharge.

-

The second shortcoming is that the current, given by a transistor at some

known bias on its base/gate, does sufficiently depend on the temperature of

the transistor. For the current regulator not to "bend for the weather", both

transistors should be installed onto the same heatsink as close to each other

as possible. But still the temperature characteristics of transistors of even

the same type have some variations. And here we are to use completely

different ones. As the result the stabilization setting floats away with the

circuit heating up. It may go lower or higher dependently to the

characteristics of transistors taken and their position on the heat sink

relatively to each other.

-

The third serious drawback is that not any pairs of transistors are

compatible. One can easily understand, that if, say, current-setting shoulder

contains a germanium transistor (even with npn structure) and the forcefull

shoulder contains a silicon one, the circuit won't work just because the

voltage drop over the base junction of the germanium transistor will be never

enough to open a silicon one. Even more serious the problem is with MOSFET's.

The gate voltage needed to open MOSFET can vary to the large extent dependently

to the type of the MOSFET. As an example 'common MOSFET's' versus 'logical

level MOSFET's' can be used. They wouldn't work when isnstalled in pair to

the current mirror circuit. And still even in the limits of one class of

transistors there are no warranties too. A pair of common MOSFET's having

typical gate opening level or a pair of bipolar power transistors may appear

to be incompatible too. In fact it means that for each task (for each given

value of current stabilization and for each given feeding voltage) one should

carefully select a compatible pair of transistor types. Once he pair has been

selected (e.g. 2n2222 from Fairchild and 2N3055 from STM) one can reproduce

the circuit at any time with maybe minor corrections of current setting

resistor for each sample. But if one of the transistor types becomes

unavailable for some reason, You will suddenly find Yourself at the very

beginning of the road, with the necessity to redesign the circuit one again.

"And why on the Earth I need this circuit?" - You may ask.

The first answer is typical: The more variants of solution You have the

higher probability that You can elaborate the task successfully. The second

answer is a bit less trivial: this is the most low voltage circuitry among

the simple ones I know for these purposes. It lacks current sense resistor

in series with the load, and thus it lacks the voltage drop over it. If

the required control voltages are low enough (e.g. if it uses a pair of

bipolar transistors) one can feed a powerfull infrared diode from only

one Li-ion cell. Even when it is seriously discharged.

For tests and demonstrations this circuit was assembled. I'm not rich in bipolar

transistors, so the pairs were to be choosen from what was around. From what I had

I was able to select the compatible transistors only among pnp ones. In the

current setting shoulder of the circuit there stands russian kt644b transistor

and a pair of kt818g in the power shoulder. Why a pair? Because sole kt818g was

unable to permit the needed 3..5 Amps of current when the supply voltage was

3.7..4 Volts.

Besides this is another method to choose proper transistor. If You are unable to reach

current high enough, You can install several transistors in place of single one.

When R1 resistor in the current setting shoulder was 4 Ohms, the circuit stabilizes

3 amps, and when R1=3 Ohms it sets the current to about 5 Amps.

The next photo shows how a 5 Wt rated infrared diode works being fed by this circuit.

For now the power is not spectacular (after those NUBM08, NUBM44 and NUBM31T) but this

is not the sense. The sense is that the diode works successfully from a single Li-Ion

cell and the current is stable enough.

The next picture shows how to cook a current mirror on MOSFET's

It was said above that it is difficult to choose a proper pair of MOSFET's, especially among the logical level ones. It is because they have very different threshold voltage. To overcome this in the circuit above a 0.1 Ohm resistor was placed in series with M1 source. It helps to stabilize the operational point and to minimize the influence of threshold voltage difference.

The next photo shows how a 5 Wt rated infrared diode works being fed by this circuit. Note that only one Li-Ion cell is used.

Return to contents Return to contents

PWM TYPE POWER SUPPLIES

↑

"Only seven notes in melody..." - they say when want to express that there's

nothin new in the world and any things could be invented are known already.

The same saying gets into mind when trying to get into the technique of

pulsed power supplies for laser diodes.

The number of possible variants of topology of circuit, allowing to pump

the energy from source with one parameters into some load with another

parameters, is not very high. I've counted 7 of them:

- 'Boost topology' (step up converter)

- 'Buck topology' (step down converter)

- 'Buckboost topology' (step up and down converter)

- 'Cuk' topology

- 'SEPIC' topology

- Flyback converter with transformer

- Forward converter with transformer

- Alternatives

Naturally there are even less of the really different variants, due to

the fact that Cuck, buckboost and SEPIC circuits are equivalent to series

pair of buck and boost circuits. One may find explanation of this here

or in Wiki articles found by keywords: Cuk, buckboost and SEPIC. A flyback

converter is logically a boost one, but with throwing the current from one

winding of its transformer to another via common magnetic flux.

Concerning alternatives, that includes many types of circuits with reactive

ballast, stabilizers with resonant tank circuit or any kinds of charge pumps

(including forward and reverse Marx banks), one may conclude that all these

circuits do not provide high enough efficiency while being too large and

weighty. At the end of this part we shall consider a few examples from this

area, but now let's return to the "mainstream".

To start with, let's consider a 'boost' topology. The next picture contains

its basic circuitry and current trace in its load.

To make the explanation easier one should remember that modern forcefull

field controlled transistors MOSFET's have negligible resistance of their

channel when they are fully open, and have almost infinitive resistance

when they are closed. So one can treat them just like a key.

The working cycle begins when positive bias comes to the gate of the

transistor. When open the transistor shorts the right (on the picture) lead

of the inductance to the ground (to the common wire). The inductance begins

to conduct a current, and to accumulate energy correspondently to the

E=L*I^2/2 law.

Then they cut the bias from the gate of the transistor. Transistor shuts

and disconnects the battery-inductance circuit. The current, having been

accumulated in the inductance, just has no other way to move, than to go

to the load through the diode.

Then the cycle repeats itself. They open transistor again and the right

lead of the inductance starts to be connected with the ground. But along

with this the left (on the scheme) lead of the diode appears to be connected

with the ground too. It means that while the transistor-key is shortened,

the current can not go through the load. One can see this on the trace.

Thus the 'boost' topology provides intermittent current through the load

and nothing except anti-ripple capacitor can cure this. Surely one can

modify the mutual positions of the load, key and inductance, but in this

case it will be something else rather than 'boost'.

Why the intermittent current is that bad? Generally laser diodes can be

fed with pulsed current, provided that their maximal allowed current was

not exceeded even in the peaks of pulses. However while the current is zero

(or too low) diode does not emit. So the average output power will be equal

to the power rating of the diode multiplied by duty cycle. I doubt that anyone

would buy a five watt rated diode for only to achieve some silly 1.5 watts

from it.

Why the anti-ripple capacitor is that bad? It would not be bad at all, if

laser diode had maybe a non linear but still monotonous dependence of voltage drop to the current. It's

a pity but it is not true in reality. At any moment, due to heating, or due

to back light, laser diode can suddenly increase its conductivity and the

anti-ripple capacitor will readily discharge into it to make an excess of

top allowed current limit. One can overcome this by installing some regulator

between the anti-ripple capacitor and the laser diode. For example one can use

an analog current regulator like one described <here>. However in this case

the main functions of current setting and current regulation belong now to

that additional regulator and not to the 'boost' circuit under consideration.

The next picture carries a basic circuit of 'buck' topology along with

trace of its load current.

Here the principle of operation allows to achieve continuous current in the

load without any anti-ripple capacitors. As the result this topology is of

wide use for any kind of current regulators for laser diode drivers. Several

variants of circuits of this type will be discussed in details further on.

The next picture depicts a basic circuit of 'buckboost' topology and

trace of its load current (at low duty cycle of control pulses, applied to

points A and B).

The circuit has two modes of operation. Conditionally speaking one of them

can be called 'boost-like', when most of the time transistor is in 'ON' state

and only for short periods they turn it "OFF", allowing the inductance to

pour its current to the load. In this mode of operation the current in the load

behaves mostly like current in common 'boost' circuit: it has shape of short

pulses with long pauses. It is obvious that this mode is of no use for laser

diode feeding for exactly the same reasons as it was in common 'boost' circuit.

Another mode of operation (let-s call it 'buck-like') appears when the

transistor is shut most of the time and allows the current in inductance-load

contour to circulate freely. And only for short intervals they turn the

transistor on to allow the inductance to accumulate energy from power source.

In this case the load current may be high enough during almost the whole

operation cycle. However in the contrast to 'normal' buck circuit, here

that 'almost continuous' current will still have short dropouts to zero.

During 'charge-up' periods the voltage of power source appears to be applied

through the open field transistor to the cathode of decoupling diode D1.

Moreover this voltage appears to be applied opposite to the current in the

load-inductance-diode contour. As the result this voltage causes the diode

D1 to shut and causes the intermittence of the load current.

It is understandable that this shape of current does allow to make a power

supply for laser diode at least in principle. The laser diode will be able

to output most part of its power without anti-ripple capacitor. However

one will meet some obstacles when trying to do it in practice.

The first to mention is noise. Noise of switching of the decoupling diode,

repeatedly applied opposite voltage through its non zero capacity, and so on. These noises not only make measurements more complicated, but also most of

manufacturers have the sole opinion that noises aren't make life of laser

diode any healthier.

The second drawback, making practical use of this mode not any easier, is

that the needed excess of feeding voltage is too high. To make the percentage

of the laser diode power available to be high, one needs to make the duration

of charging periods as small as possible. And in order for the inductance to

get enough energy in time, one needs to apply high feeding voltage. Usually

not less than triple of the voltage drop over the laser diode.

The third shortcoming is that at given frequency the 'buckboost' circuit

will require much higher inductance than normal 'buck' does. And it will

hit to the efficiency, to the mass, and to the sizes.

The only advantage of the circuit if the protection of laser diode, Indeed,

in case of failure of control of the transistor, or in case of its burning out,

the load becomes disconnected from the power source by the decoupling diode D1.

Hereby the current goes to the load only when the power supply works correctly.

And in case its burn the harm will be minimal.

Safety of laser diode is good thing, but the price to pay for this is not

very affordable. Worth to note that the safety is not 100% too. Imagine what

will happen if battery V1 was connected in reverse polarity? The MOSFET

would conduct without any respect to signal at its gate - its internal

diode conducts in this case. The decoupling diode D1 is also out of help here.

So if the power source is able to create enough voltage drop over L1 coil

(or even to burn it out), then the destruction of the load is sure. It is

evident, that one can connect another diode in series with the circuit to

ensure the correct polarity, but it is an additional measure, not relevant

to the circuit under consideration. Moreover, in a real circuit the contours

"battery-MOSFET-coil" and "coil-decoupling diode-the load" may be

interconnected via circuits of control and feedback, and it gives additional

weaknesses in the safety system. So, the 'buckboost' circuit is finally of

low use to be a main current setting and current regulating element of

laser diode power supply.

Generally the mode, where the current dropdowns are short enough and most

of the working cycle the current is close to nominal one, can be realized

in most of the circuits that provide intermittent current (SEPIC, flyback

and forward ones) but the drawbacks would be the same.

Cuck and SEPIC provide even more level of safety, because the load is

separated from their power source not by diode, but by a capacitor.

SEPIC circuit is shown on the picture below.

One can find the detail description of its operation for example here. Similarly to 'boost', SEPIC can not provide continuous or almost continuous

(with short dropdowns) current through the load. Correspondently, like 'boost'

it cannot serve as main current setting and current regulating element of

laser diode power supply.

CuK topology circuit ad its trace of load current in mode, nearly optimal to

feed a laser diode are given on the next figure:

One can see that the circuit allows to get a mode, where average current

through laser diode is close to its peak current. So the circuit is, at least

in principle, applicable as main current setting and current regulating element

of laser diode power supply.

However there are a few underwater rocks, waiting for those, who wants to

use it. The first: the separation capacitor C1 accumulates and stores electric

charge in process of operation of the circuit. If this capacity is large, the

accumulated charge may be high enough to destroy laser diode. C1 capacitor

behaves not exactly alike an anti-ripple one, mentioned above, but still

is hazardous to the health of laser diode. One may consider that the constant

component of the voltage across C1 may be treated as an incoming parameter

for the 'buck' stage of the circuit (it was already mentioned above, that 'CuK'

circuit may be imagined as 'boost' and 'buck' circuits, connected one after

another and with consequent optimization for number of parts used).

One of the bad effects of the charge, accumulated by C1, is that it brings

a delay into the current regulation circuit and may completely destroy the

mode of stabilization. If it happens the power sully becomes nothing better

than common voltage regulator and it is the direct way to burn Your laser

diode. On the other hand, if C1 is small enough, the circuit becomes more like

charge pumps (see below) with all their drawbacks.

With taking the slow charge, accumulated in C1, the dependence of current

through the load to the duty cycle of Cuk circuit becomes not only non-linear,

but even non-monotonous function, and it makes the task of current control

to be even harder to perform. (One can note here, that the dependence of

output voltage Vout to the duty cycle d_c for common CuK voltage regulator

is given by: Vout=Vin*d_c/(1-d_c), where Vin - is voltage of power source.

This function is monotonous and makes the task of voltage regulation to be

trivial).

Thus CuK circuit is the second (after 'buck') candidate to the role of the

main current setting and current regulating element of laser diode pulsed power

supply, if one is able (and wants) to overcome the difficulties in its

control. However as CuK circuit may be represented as sequentially applied

boost and buck circuits, one can treat this variant as a variety of the first

one.

Transformer based circuits provide even higher level of safety in case of

power supply failure. Generally they do not require any galvanic

interconnections between load contour and supply contour at all.

Circuit and load current trace for a flyback converter are, as usual, on

the picture below.

It have already been said that flyback converter is logically 'boost' one,

but with throwing the current from one winding of its transformer to another

via the common magnetic flux. Flyback circuit generally obeys the same rules

as the 'boost' one and similarly just cannot provide continuous load current.

So, like 'boost' it is unsuitable for use as main current setting and current

regulating element of laser diode pulsed power supply.

As to forward converter, due to the presence of transformer it generally

can not provide continuous current through its load too. There is, however

a special case - when the transformer is fed by 50% duty cycle rectangular

pulses and the load is connected via diode bridge.

One can ensure that any deviation of the feeding pulse shape from symmetrical

one (relatively to mean or weighted mean level) causes dropouts or even pauses

in the load current. It is illustrated on the next picture.

If one must keep the symmetrical shape of pulse to provide a continuous

current through the load, on can no more vary the duty cycle to provide

regulation. To feed the primary winding with trains of symmetric pulses of

variable duration is silly alternative too. The pauses between those trains

will cause pauses in the load current - there is no anti-ripple capacitor,

so the load current shape will repeat the ramp of the trains of pulses.

Now all the main variants of pulsed power convertors have been discussed.

It was found that only 'buck' converter is suitable as main current setting

and current regulating element. The buck, or circuits equivalent to it.

Thus if not taking into account roundabout alternatives, the modular scheme

of pulsed power supply for laser diodes can be reduced to sequential application

of three units:

- Primary power supply

- Voltage converter - regulator

- Current regulator based on 'buck' converter or equivalent.

In more complicated cases there may be present some control circuitry,

providing, say, adjustment of power of laser diode according to user

commands, or 'blinking' in one or another mode.

Primary power supply here means battery (accumulator) or mains rectifier.

Stabilized voltage converter may be designed according to millions of known

schemes. The main thing, it must perform, is to provide match between

electromotive force and internal resistance of the primary power supply

and the necessities of the unit, that performs current regulation. SInce

the load for the voltage converter is not capricious laser diode, but

rather tolerant buck converter, here You may use any anti-ripple capacitors

and filters You want. The voltage converter may be absent at all if the

parameters of primary supply are more or less matched with what is needed

for the pulsed current regulator. This scheme is of most use for portable

lasers, where size does matter. Accumulator battery serves as the primary

supply in this case.

Before we proceed to consideration of 'buck' type current regulators, I

want to mention yet another variant of laser diode power supply building.

It is a hybrid variant, consisting of pulsed voltage converter- stabilizer,

loaded by an analogue current regulator. If the DC-DC invertor provides

no more voltage than needed for normal operation of analogue current

regulator with no excess, one can expect that efficiency of the analogue part

will be high, and the heat output will be low.

The next circuit may serve as the example:

It consists of a SEPIC voltage inverter, utilizing 555-th timer as a PWM

controller, and transistor U2, used as the main switch. Coils L1 L2, capacitor

C2 and diode D1 form the barebone of SEPIC circuit. Further on is triple section

filter L3-L7, C3,C9, C10 goes, and its output is connected to analogue current

regulator, built according to a simple two-transistor circuit Q2, U3. The

latter circuit is described in details in the part SIMPLE ANALOG CURRENT REGULATORS.

Resistor R15 and filter R10, R13, R14, C11 are used to make path for feedback

signal, that drives Q1 and U4 transistors, which, in turn, cause changes in

duty cycle of the 555-th timer's oscillations. R7 R4 divider is used to tune

the circuit to the state, where the voltage, given by the pulsed part of the

scheme onto its analogue part, stops to rise when it becomes a pair of volts

higher than the threshold voltage, when current starts to flow through the

load (designated as Rload on the circuit).

The circuit was intended to feed a half of NUBM08 laser diode stack (4 diodes

450 nm 4.5Wt each) from 12V automotive Pb accumulator. SEPIC was chosen instead

of buck to provide the ability to use 24V accumulator too.

The results of assemblage and tuning have shown that the circuit is fully

operational. However even when the supply voltage of the analogue regulator was

barely enough for its operation, it still requires a heatsink for U3 transistor.

Moreover the selection of SEPIC as the DC-DC conversion was not fortunate. The

noise of D1 switch and other pulsed interferencies appeared to be so high, that

it required three stage LC filter (initially it was nit foreseen in the

circuit). As the result the device became cumbersome and have not found any

practical application. The results given by 'buck' current regulators were

far better.

Since the analysis given above shows special role of buck converters (for

not to say their unique role) for pulsed power supplies for laser diodes, let's

discuss this type of converter more closely. It consists of some control

circuit (so called PWM-controller), switch transistor and a coil an diode,

placed as shown on the next picture:

If one follows this layout straightly, there arises a problem of high side

switch. On the other hand it is not necessary that load circuit and control

circuit have common ground. If one avoids this the circuit may look like this:

No more high side switch problem.

Further on, for this circuit to become a complete current regulator, one

has to introduce some feedback, that will shorten the 'on' phase of switch

when the current is too high and prolong the 'on' state when the current is

too low. And the first that will be required for this feedback is some element,

giving a signal proportional to the load current. In the simplest case it might

be some resistor connected in series with the load:

Having introduced the feedback by this way we shall get some current

regulator based on 'buck' converter. Let's call it 'white buck'. Why exactly

'white' will be explained further on.

The given way to read the load current is certainly correct, but gives

a rise to several difficulties. First of all is that the signal from current

sense resistor is relative to the positive common wire, while most of control

circuits require the one relative to the negative wire. The problem of signal

level shifting is to some extent similar to the problem of high side switch

and generally has no simple solution especially for high supply voltages.

The second inconvenience of the described method of current sense resistor

connection is that the load appears to be not connected to any of the common

wires. Neither to positive nor to negative one. Why it makes so trouble? Let's

remember that the load is actually laser diode, despite the fact, that it was

designated as Rload on the picture. And most of laser diodes have positive or

negative terminal electrically connected with their casing. Moreover, in most

popular designs of lasers they put laser diodes directly onto some wall of

metal casing. Both facts cause the situation, where the casing of the laser

device authomatically becomes a common wire (or at least backs it up).

If one then wants to introduce a current-sense resistor to between the

diode and the common wire, one needs to insulate the diode from the casing.

It is not trivial task and get ready to loose the efficiency of the heatsink.

While looking onto the circuit one may note that when the transistor is open,

its drain current is almost equal to the current through the load. And when

the transistor is shut, the load current can never exceed the one, that

was when the transistor was still on. So, with some minor loss in precision

one can severely gain in robustness if the current-sense resistor was moved

outside the L1-D1-Rload contour:

Users of internet forums often call this topology 'blackbuck'. Strictly

speaking this term is not commonly established one, but still it is

rather wide spread and very handy. Here I will use it further on.

In the 'blackbuck' topology the current-sense resistor is outside of

the contour with load, so the measurements are a bit incorrect, and one

can say that they are conducted in the 'black' way. On the contrary,

when the current-sense resistor is inside the contour with load, one

can say that the measurements are done in the 'white' way and call this

topology as 'whitebuck'. This explaines the name, having been used earlier.

As a control circuit for whitebuck or blackbuck one can use one of

numerous chips, known as 'PWM-controllers'. One can also use any other

circuit, provided that it contains comparator, Schmitt gate, and a delay. Proverbial 555-th timer chip contains all these components and is commonly

used as a simple PWM controller. One should however remember, that laser

diodes are usually powerful load and to feed them a circuit with external

powerful MOSFET is needed. 555-th timer has poor load capacity of its

output terminals and thus require external buffer stages or special

driver chips to control the MOSFET at the frequences needed.

GATE DRIVER INTEGRATED CIRCUIT - IS A TINY AND COMPARATIVELY

INEXPENSIVE CHIP COMMONLY USED TO REPLACE A CUMBERSOME HEATSINK OF YOUR

MOSFET

There are plenty of gate driver chips, that can provide the necessary

speed at the currents required. One can mention TC442x, MIC442x, UCC3732x,

1EDN75x, ixdd414 series. Dont bother with something like IR21xx - maybe

they work good with high voltages, but they are too slow for our 'laser'

purposes.

The desired conversion frequency is like 200..500 kHz. In this range it

is high enough to provide small sizes of the circuit, and still low enough

for many common ferrites to operate with, and for the time of MOSFET switching

to be negligible with the working cycle period.

An example of 'blackbuck' current regulator is given on the picture below.

The circuit is made in a 'good manners' style of pulsed power force

electronics: each stage has decoupling over its power line (D1 diode and C2

capacitor for master oscillator on 555th timer, D2 diode and C3 capacitor

for 4420-th gate driver stage), the gate of U3 transistor is 'grounded' through

R7 resistor to avoid spontaneous opening due to statics, when outputs of

4420th are shut. The power line of 4420-th is shunted not only with

electrolytic capacitor C3, but also by a ceramic one C4 (100nf). C4 should be

mounted directly to the legs of 4420th. Feedback signal is filtered by

R8C5 from the high frequency interferencies. In addition to this the schematic

explicitly shows the current sense resistor being formed by four resistors

(R3, R4, R5, R6) connected in parallel and each having the resistance of 1 Ohm.

One can set the desired current of laser diode by connecting and

disconnecting the necessary number of resistors. Further on in this text

the current-sense resistor won't be drawn in such a details. If in this place

of circuit You see 0.25 Ohm resistor, You should get it as: "for resistors,

one Ohm each, connected in parallel, and measures are taken to make it possible

to connect and disconnect any of them at any desired time."

I seriously recommend You to use LMC555 chip as a 555th timer. This chip is

logically full analogue of the common NE555, but it is made with CMOS

technology and it is able to operate at frequences as high as 3 MHz. Common

NE555-th are either not operational at all at the necessary frequences, or

just unstable. MOSFET may be of any kind, intended for 20 or more amps of

current and 20 or more volts of supply voltage. IRLU2905(IRLR2905) is

interesting due to it has little resistance when open and occupies a small

casing DPAK(IPAK). Additionally this MOSFET has logical gate level, and,

though it is not completely necessary, it is very useful from many points of

view. As for D3 diode - You can use any Schotkey, rated to 5 Amps or more.

Its reverse breakdown voltage is of low importance here, but still it is not

very good idea to choose it below 30 Volts.

Having assembled the 555-th stage check it for oscillations. In the absence

of feedback it should give rectangular pulses with repetition rate of

100-200 kHz. Duty cycle should be 80-90%. If the frequency differs too much,

adjust value of C1 capacitor. If the chip does not oscillate, or duty cycle

is too low, adjust the R1/R2 divider. R1 and R2 values on the picture are

related to LMC555 as the timer and 8.4 Volts power supply (two Li-Ion

accumulators in series). If using another type of 555 timer or very

other supply voltage, most probably You have to adjust the divider.

Remember, that the duty cycle is in non-linear dependence on the R1 to

R2 ratio. Also, when R2<2*R1 the circuit does usually not work.

When settled with 555, assemble the 4420th gate driver's stage. Check its

proper operation, by loading its output with some 5-10 nf capacitor instead

of the real MOSFET gate. The driver should transmit the pulses properly.

Rise and fall of them should not be too long, and there should be no 'ringing'.

Then assemble the forcefull stage on MOSFET, and add the feedback loop (R8,

C5, Q1). Attach an 1 Ohm resistor to the output instead of laser diode, and

let only one from the set of current-sensing resistors to stay connected.

Turn the power on. Measure the current of the load and duty cycle of 555-th

timer. The output current should be somewhere around 0.5 Amp, and duty cycle

should be much less than it was for the free oscillations. Shrinking of the

duty cycle is the result of feedback loop operation. If it does not function

properly the circuit will not provide constant current.

After the full assemblage and preliminary tests, check the quality of

current stabilization. Attach 0.5, 1 and 2 Ohms to the place of load. (Only

one at a time! Clever ones, - sorry for this note.) The output current Will

change with change of load (it's normal ' cause it's not a whitebuck). But

this change should be not over 20%. Also check for the absence of surges

during turning the battery 'on' and 'off'. (For this to perform one should

have a memorizing oscilloscope. Note that some digital scopes have poor or

even inoperational 'single' mode. These scopes are out of help here.)

Check if the ripple amplitude is good for Your purposes. The ripple amplitude

is tied directly to the ratio of L1 inductance to the resistance of the load.

If the ripples seem too large for You - choose higher frequency (by making

C1 smaller) or increase L1 inductivity. Keep however in mind, that with too

many of turns You risk to hit the ferrite core saturation. The circuit

will loose operationability if this happens.

During measurements You will suffer from pulsed interferences. The cheap

'household' oscilloscopes usually have poor shielding and they can show

false surges. If on the nice background of fine zigzag of current in the load

You see sharp needles, several amps in amplitude and 10-100 ns in duration,

remember that they physically can not exist. L1 inductivity is just unable

to let them pass through the load.

After having been convinced in the correct current regulation and absense

of the surges during turnin on and off (and also during mechanical shocks)

You can replace the load resistor by a real laser diode. The circuit is

designed to feed laser diodes by currents in range of 0.5-5 Amps. Most

single powerfull diodes match this range. The voltage drop across diode is

not very sufficient. You can feed GaAs (red and infrared) as well as GaP

and GaN diodes (blue, green and ultraviolet). If one wants to use the circuit

to feed numerous diodes connected in series, the circuit must me modified.

Further simplification and size reduction may be achieved if one gets

rid of the separate master oscillator stage (on 555-th timer or other

PWM-controller). Note, that gate driver does already contain comparator

and Schmitt's latch, so the gate driver itself can be a decent oscillator.

Blackbuck topology circuit using 4420 (non-inverting) gate driver is shown

on the next picture.

As You can see in order to reduce the PCB footprint, elements of decoupling

of the 4420-th stage from the forcefull part were omitted here. The current

sense resistor is also shown in a brief foem - as a single resistor. Resistor

R4 is optional. It is used to prevent too much of gate ringing. If Your sample

of circuit does not suffer from this You can omit it. If You want make it as

small as possible, and if its supply voltage is low, You may omit D3 diode,

which is used to protect the base of Q1 transistor from reverse voltage. You

can even omit C4 capacitor, intended only to make the range of oscillations

wider.

As earlier C3 capacitor is to be mounted directly to the legs of the gate

driver. The requirements to the powerful MOSFET an to D1 diode are the same,

as they were in the above circuit on 555th timer. D3 diode can be of lower

power: ~1 amp rated and 20V of reverse voltage. Almost any signal npn silicon

transistor can work as Q1. Keep an eye, however, that its allowed collector

current should be not less than 50 mA, and its allowed collector-emitter

voltage must be at least several volts higher than the voltage of Your

battery. At higher voltages, to keep the collector current in safe limits

one might need to increase R3 value. This affects the behavior of the circuit

in rather complicated way. One could say that it shifts the range of loads,

where stabilization is effective, towards higher resistances. Usually it

is not desirable and should be avoided, so You might better to consider

using a more powerfull transistor in place of Q1 rather than increasing R1.

If using SMD-components one can make the circuit as small as 25x15 mm,

that allows to place it into a body of powerful laser pointer.

I'm not specialist in the area of ferrites, so i cannot advice any good

on L1 coil winding. You should either buy a ready choke rated to 15-20 uH

and 5 Amps of current or to choose the right ferrite core by Yourselves.

Dependently to the ferrite used, the number of turns may be in range of

5-15. The wire should not be too thin. Enameled copper wire having diameter

of 0.5-0.75 mm gives good results.

On the contrary to the previous circuit this one is a sole and complete

stage and cannot be debugged by parts along with its assemblage. Having

soldered it up, connect an ~1 Ohm resistor to its output instead of laser

diode. Set the current-sense/current-setting resistor R1 to 1 Ohm to begin

with. Turn the circuit on and observe the oscillations with an oscilloscope.

If there is no oscillations, try to increase the capacity of positive feedback

capacitor C4. (Generally the oscillations should be, and their absence mean

something gone seriously wrong. Trying to enforce them by C4 is like trying

to revive a dead body, but all is up to You though.) When the self

oscillations are stable, adjust C1 capacity to set their frequency into the

correct range. Generally R3-C1 works as frequency setting chain? use it

to make it in between 200..400 kHz.

Proceed then to the measurements of current stabilization quality,

When load varies in range of 0.5..2 Ohms the current should vary not more

than by 20%. Generally most of the said about tuning of the circuit on 555th

timer applicable here too.

After all adjustments and checks for absence of surges You may connect

a real laser diode to the output of the circuit.

In the given form the circuit allows to feed single laser diodes with current

in between 0.5..5 Amps. If one provides an independent power source for

4420 chip and Q1 transistor, and then to increase the supply voltage for the

forceful part, the circuit becomes able to feed garlands of laser diodes

connected in series:

If Your battery is of low voltage type and Your laser diode is of nitride

type, it may be not so simple to convince the circuit to give more than 3 Amps.

(Indeed, two lithium-ionic accumulators may mush down to 6 volts under the

heavy load. Voltage drop across the laser diode itself is around 4.5 Volts.

Finally the circuit itself has only 1.5 Volts 'to hum'. To reach, say, 5 Amps

the sum of all stray resistances must then be less than 0.3 Ohms. Subtract

the current sense resistor value and You will get 0.2 Ohms for all the

circuitry, including MOSFET's channel, the coil and the strips on the

PC-board.)

However one could easily solve this, because 'blackbuck' topology drivers

are easy to parallel. For better stability one should add decoupling diodes

at their outputs? as on the following picture:

Next to the schematics there is a (simulated) scope trace of the current

through the laser diode. Right and left 'blackbucks' were turned on and off

not simultaneously, and it can be seen on the trace.

Since the circuits operate independently, their sum current ripples have

shape of beats between the frequences of oscillations of both circuits.

In their maximum they can be the arithmetic sum of ripples given by each

circuit. This fact should be taken into account when using several drivers

in parallel. One should either increase the safety margin when selecting

the necessary current for laser diode or take measures to reduce the ripples

(increase frequency or increase inductances L1 and L2).

Whitebuck topology circuit is better to be assembled using an inverting

gate driver (like 4429):

Current-setting and current sensing resistor here is R3. The principle of

operation is very simple: as soon as the current through the load reaches the

certain value (defined by R3 value) Q3 transistor opens and gives positive

bias onto the entrance of inverting driver. This shuts the MOSFET and causes

smooth decreasement of current through the load. After the current has become

less than the preset value, the gate driver can not switch to on instantly,

because the positive bias at its entrance is 'memorized' by C1 capacitor.

Only after its discharge via R1 the circuit can connect the supply voltage

to the contour of the load - the working cycle repeats itself.

Aside of the general shortcomings of all whitebucks (that load has no common

with common wires) this particular implementation of the circuit has numerous

drawbacks of its own. The problem of signal level shifting is solved here by

the most simple way: with a help of a stage on pnp-transistor Q1 with load R1.

This simplicity begins to cause troubles when supply voltage goes higher. And

if the circuit works best when the supply voltage is 8.4 Volts (2xLi-Ion), it

becomes hard to get the necessary duty cycle at 12 Volts of supply. At 24 and

of course at 36 V the circuit becomes inoperational. Note that LTSpice

simulator does not discover this problem. Further on, in order to get the

proper dependence of the duty cycle on the load value, Q1 transistor has to

have a smooth transient characteristics. Russian KT3107 works well here, and

its (said to be) analogue 2N3906 - does not.

One may ask, why mention this circuit if it has so serious shortcomings?

The answer is that any mice trap contains its own piece of free cheese. The

main advantage of this circuit is that it makes the current to stay as

wolverine tail in frosty night. If it was normal for blackbuck circuits to

change the current by 20% when the load changes by 4 times (from 0.5 to 2

Ohms), for 'whitebuck' scheme it is hard to note any change of current with

'household' measurers during the same load variations. Keep in mind, however

that if its supply voltage changes strongly (e.g. from 8 to 12 volts) one may

need to recalibrate the current setting resistor.

Due to the fact that circuit behaves poorly with increasement of the supply

voltage it cannot be rearranged to some 'high voltage' variant to feed garlands

of laser diodes (as it was with 'blackbuck').

There are some specialities with its paralleling too:

One cannot connect together any common wire of the circuits. And the

decoupling diodes are the must here.

The given circuits certainly do not cover all the variety of 'buck'

converters or equivalent to it circuits. There are all kinds of self

oscillating ones like the above on 442x, and all kinds of externally driven

ones (like the one with 555timer). Control circuits and logic of feedback

operation may be very sophisticated, including tenth of protections and

limitations.

A separate attention is to be paid to multiphase circuits. It was said

above that several pulsed current regulators may be connected in parallel

to a common load. However in the discussed case the drivers worked independently

and their ripple voltages summated. And if several pulsed current regulators

are united by common control circuit, that enforces each regulator to be

in 'on' state only while others are in 'off' state, the resulting scheme is

called as 'multiphase' one, and the ripples are no more to be added to each

other. The power of this approach is so high, that even a multiphase 'boost'

converter may yield a decent source for a laser diode. However the price

is high too: N phases mean N MOSFET's, N gate drivers, N coils, microcontroller