First time I knew about the inconvenient properties of the carborundum

from Jon Singer web reports, where he tried to use this substance to make

a preionizer for a nitrogen laser. However the success was rather poor,

and it is understandable that no will for attempts to reproduce this scheme

was arised. Moreover i already had a negative experience with attempts to

use a distributed resistance (in form of Bealieau schematics or capacitive

discharge). While the energy is low - the beautifull glow, and when You

try to reach laser level of energy deposition, the discharge contracts and

nothing helps.

Then a canadian article [1] appeared before my eyes. They praised silicon

carbide and a preionizer made of it. Their preionizer worked not worse than

a multi-spark one, but was much simplier and easy to build. However they

used a helium rich mixture (He:N2:CO2=70:15:15) and transition to air

substituted ones looked at least doubtfull.

At the third time silicon carbide hit my nose, when i tried to find in

literature some light on the process of huge energy dissipation in nitrogen

lasers. As usual: when You are looking for something, You find the very other.

The French article [2] reports that they succeeded to make working laser not

only using a heliumless mixture, but using a CO2:N2:O2=48:42:10, and that is

pretty close to using the air. (Actually the air containing mixture differes

from that one only by uncontrollable contaminations.)

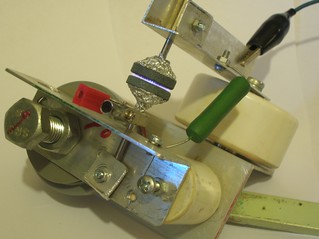

Such a kick is hard to ignore so I had to give it a try. The silicon

carbide was found in form of grinding discs for hand engraver tool (dremel

tool). All that was needed, was to connect them to a little test circuit:

SG

+---> <---+-----+---------+

! ! ! !

! ! ! !

+----||-----+ \ !

! Cp / Rl XXXXX

! \

--- / XXXXX

--- Cs \ !

! ! !

! ! !

+-----------------+---------+

SG - air filled spark gap. Cp - peaker capacitor Murata 590 pf x 40 kv,

Cs - storage capacitor Murata 2 nf x 40 kv. Rl - leakage resistor

(connects the opposite to the storage capacitor plate of the peaker to

the ground wire) 5.6 kiloohms,

The 'XXX' means silicon carbide electrodes.

The result impressed me (see photo). Such an even and bright rain of sparks

I havent ever seen from any Bealieau circuit. And this sparky rain is

accompanied with a violet fog of a diffusion discharge.

For the comparison here are the photoes of a discharge with analogous

grinding discs made of corund (Al2O3).

Despite the fact that the material is porous, it does not want to disperse

the spark. I.e. the reason of such a nice discharge with carborundum does

not hide in the fact that the discharge goes through thin pores between

abradant grains. The matter of fact is the conductivity of the carborundum

itself.

The test had clearly shown that at least as a preionizer this thing is

more than acceptable. And in better case it is good as a laser electrode.

However the hand engraver tool grinding discs arent best fit to make laser

electrodes. The search for the carborundum bricks in all nearby hardware

stores brought nothing. I had to make some web serfing. Finally those bricks

vere purchased:

Despite that all of them (if trust the seller's price list) were made

of carborundum, in the test circuit they behaved differently. The bricks of

the first type (dark greenish grey, with large grains and pores size) give

dispersed rain of sparks as it was with Dremel's discs. The bricks

of the second and third types (greenish white, finely grit and nonporous

looking) behave like dielectric. It means the spark goes way around and

there's nothing between the bricks.

The bricks of the first type are 100x10x3.5 mm sized. The first test

laser was assembled with their use.

TEST 1

A laser tube was assembled. Its electrodes were formed by 100x10x3.5 mm

carborundum bricks. Three bricks per each electrode. The bricks have rather

foolish shape, so I slightly cut them to better fit the electrode keeper.

It appears that the carborundum bricks can be very easily cut with any diamond

tool. After the assemblage the active length of electrodes appeared to

be 285 mm.

The gap between electrode keepers was set by a props 10 mm thick. As the

result, the spacing between the laser electrodes became slightly less than

3 mm (were the bricks 3 mm thick, as it was said in the catalogue, it would

be 4 mm, but in reality the bricks appeared to be thicker).

No preionizer was introduced at this step. It was interesting whether the

silicon carbide could make all by itself.

The gas-discharge unit was put into a cut of plastic sewe pipe having

diameter of 50 mm and length of 300 mm. The ends of the pipe were shut by

perspex alignment mirror mounts. The back mirror was (as usual) the aluminium

coated concave automobile rear view mirror with its protective painting

having been removed. The front mirror was dielectric coated ZnSe with

75% reflection. The mirror was noticeably contaminated by a gas torch flame

in the vain attempts to make vacuum tight seal with a hot glue (glue-gun).

The distance between mirrors is 350 mm.

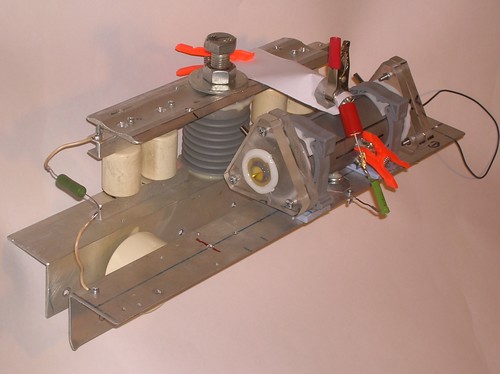

The laser tube was installed onto a frame with capacitors and spark gap

(that was left from a previous laser project). The resulting scheme is:

SG

+---> <---+-----+---------+

! ! ! !

! ! ! !

+----||-----+ ) !

! Cp ) Ll XXXXX

! )

--- ) XXXXX

--- Cs ) !

! ! !

! ! !

+-----------------+---------+

SG - air filled spark gap (the gap value is usually set to doubled

value of the spacing between the laser electrodes - matched load mode)

Cp - peaker capacitor 4 pcs Murata 590pf x 40 kV in parallel,

Cs - storage capacitor, from 3 to 7 pcs Murata 2 nf x 40 kV in parallel.

L1 - leakage inductor (shortens the circuit of the peaker capacitor

charging and limits the discharge time - 4 turns of 1 mm copper wire

in PVC insulation wound on a 45 mm corpse).

"XXX" - means carborundum

(laser electrodes)

//You should better get used to the ascii graphics. Since it is a report,

not a guide, I'm not going to slave Your habits - all the schematics will

be in the form that I usually do: no "gif" or "jpg" for simple schemes.

"txt" only. Try to adjust Your browser for not to eat whitespaces, or

just open this in a text viewer/editor.//

The laser tube run at gap values (in the SG) from 6 to 11 mm, with

the storage capacity from 6 nf to 14 nf on mixtures of CO2:air 2:1, 1:1 and

1:2. At pressures from 500 mbar to 100 mbar. No lasing was observed.

Possible reasons:

- high diffraction losses (CO2 laser radiation with its long wavelength

poorly goes through the narrow spacing between laser electrodes)

- scattering on the discharge inhomogenities (The volumetic discharge is

accompanied by more than 10 000 sparkies. Each of them is weak, but the

total scattering may appear to be considerable. And the question of the

possibility of lasing using multitude of sparks only is still dark.

Bealieu himself had reported that his laser operated "on sparks" but

nobody later reported the same. So it was possibly misunderstanding or

bad translation or bas phrase.)

- the resistance of the electrodes gives high discharge time constant,

so the current prefers to go through L1. This is enstressed by the fact

that L1 was specifically choosen for fast lasers (sqrt(CsL1)~1mcs).

L1 was replaced by a high voltage wirewound resistor 5.6 kiloOhm rated.

The sparkies in the discharge became less weak more white. And at larger

storage capacities (above 10 nF) the strength of sparks was enough to burn

through th brick of carborundum. There appeared a burnout hole with black

border. Happily was only in single place, not all over the surface.

It was decided to add a preionizer. But before telling that results a pair

of words on the other interesting observations.

It is curious that the discharge in this laser tends to contract not

at high pressures, but on the contrary at low ones. Below 500 mbar I was

not able to obtain the volumetic discharge between the electrodes. Below

300 mbar I was not able to get ANY kind of discharge between the electrodes -

any discharge goes around them as if they were dielectric.

Another thing seeming unusual to me is a black color around the burnhole.

One may suppose that it is carbon, but... the brick easily endures gas torch

heating to about white glow. And when it is cold again it regains its color

and properties. So there is no organic glue in the brick's content.

One may suppose that SiC decomposes itself, but see above... I doubt

that the spark can heat it to comparable temperatures.

TEST 2

The laser tube was disassembled and a preionizer was added. The design

of the preionizer resembles Lamberton-Pearson scheme - two wires pulled

alongside the electrodes.

SG

+---> <---+-----+---------+-----+-----+

! ! ! ! ! !

! ! ! Cpi--- ! ---Cpi

+----||-----+ \ --- ! ---

! Cp / Rl ! XXXXX !

! \ +--- ---+

--- / XXXXX

--- Cs \ !

! ! !

! ! !

+-----------------+---------------+

SG - air spark gap of the enclosed type, Cp - peaker capacitor 4 pcs of

Murata 590 pf x 40 kv in parallel,

Cs - storage capacitor from 3 to 7 pcs

of Murata 2 nf x 40 kv in parallel, Rl - 5.6 kOhm - leakage resistor

(shortens the charge contour of the peaker capacitor but unlike the

previous inductance almost does not affect the discharge time)

"XXX" as usual means carborundum, Cpi - preionizer capacitors, 50 pf each

KVI-2 type.

The preionizer wire has diameter of 0.5 mm. It is stretched along the

electrodes and placed in height coordinate exactly in the middle between

the electrode keepers (i.e. in 5 mm from the keeper plate surface).

The distance in the horizontal direction from the axis of wire to the

edge of the electrode is 2 mm. The wires are connected to the anode through

the capacitors goes not at both sides of laser (as one could suppose) but

at the end corresponding to the output mirror (I was low on capacitors that

moment).

Here I will again take an effort to remind You that this kind of preionizer

coincides the Lamberton-Pearson's one only by exterior and design. The

logic and principles of operation are completely different. Here the preionizer

uses thick wire and large capacity. And utilizes multi-spark discharge type,

that becomes possible due to the electrodes are resistive. Considering the

Lamberton's preionizer usually they say that utilizes corona discharge. And

I could simply say that it is completely different thing. However it would be

somewhat reduced thinking. The real corona is spatially limited discharge.

The ionization stops where the field is low enough. Unlike this in the

Lamberton-Pearson laser's working area there's no place where the field is

low enough for the ionization to stop. Actually the discharge does cover

all the path between the wire and the adjacent electrode. And since there are

no means to force the discharge to take distributed form, it tends to become

a "single bright arc" whenever it possible. In a very special cases when the

preionizer feeding capacitors have low value and the wire is thin the

discharge takes form of diffusion-streamer one. This one was studied in [3]

and they showed that the number of streamers increases with increasement of

voltage rising rate, with lowering of the wire diameter and with decreasement

of electron affinity of the gases. The single bright arc can not preionize

all the volume properly, so it's crucial for the discharge to have diffusion

streamer form. In practice it leads to very thin wires (below 100 mcm),

low feeding capacities, helium rich mixtures and low inductive power supply

circuits.

On the contrary here we have multi-spark discharge from thick wire to

the electrode with distributed resistance. The distribution of the sparks

depends mainly to the resistance of this electrode. Thick wire has lower

resistance and inductance. The preionizer feeding capacitors can have rather

large value. All this allows to increase power and energy of the preionization,

and moreover it allows to operate with voltage pulses having gradual front.

However despite all those advantages this preionizer is way less effective

than the one of barrier-discharge type used in laser with holed electrodes.

On the other hand it is way simplier. And when the preionizerless discharge

has the form very close to the needed one, it seems logical to begin with

the most simple solution.

And again the laser tube run at gap values (in the SG) from 6 to 11 mm,

with the storage capacity from 6 nf to 14 nf on mixtures of CO2:air 2:1, 1:1

and 1:2. At pressures from 500 mbar to 100 mbar. No lasing was observed.

The observable look of the discharge became more smooth but it seems not to

be enough.

TEST 3 (first light)

The laser tube was rearranged again. In order to increase spacing between

the laser electrodes one 1mm thick perspex plate was added to each spacing

prop. Hereby the spacing between the laser electrodes became 4 mm. The

placement of the preionizer wires was kept unchanged. I.e. they are still

at a height of 5 mm from the cathode keeper plate. The laser became asymmetric.

The preionizer wires are now placed (in vertical direction coordinate) at

5-3.5=1.5 mm from the cathode cutoff, and at 6-3.5=2.5 mm from the anode

cutoff.

The electrical circuit was kept unchanged. With Cs=6nf and with CO2:air=2:1 mixture at air pressure the lasing was observed. Almost accidentally.

It was noticed that just after the turning on of the laser the calorimeter

"behaves uneasy". Than it calms down and clearly shows zero.

Then the beam was focused onto a carbon paper. A spherical aluminium

coated mirror with focal length f=50 mm was used. Here it became visible

that the laser gives only the first 1-2 pulses in the sequence and then

dims. Due to my spark gap is of the uncontrolled type, I tried to reproduce

repetition rate change by repeatedly plugging the power supply to the mains.

It appeared that the laser was able to produce pulses at ~0.5-1 Hz (each

one or two seconds). And it was uncapable to do more.

It was supposed that preionizer feeding capacitives got charge from the

first pulse, and since the circuit is cut, they cannot discharge further on,

rather than through the huge and uncontrollable stray resistance. To take

things under control the leakage resistors were added:

SG

+---> <---+-----+-------+-------+-----+-----+------+

! ! ! ! ! ! ! !

! ! ! / Cpi--- ! ---Cpi /

+----||-----+ \ \ --- ! --- \ Rpi

! Cp / Rl / ! XXXXX ! /

! \ \Rpi +--- ---+ \

--- / ! ! XXXXX ! !

--- Cs \ +-------+ ! +------+

! ! !

! ! !

+-----------------+---------------------+

Laser got run again. With Cs=6nf and CO2:air mixture 2:1 at full

athmospheric pressure (SG1 set to 8 mm) it gave more than in the first run.

Since power is low and unstable it is hard to say anything in figures but

subjectively the output raised by about 30%. With 1:1 mixture the output

raised once more and @ 1Hz laser yield ~6 mW. It still fails if attempting

to operate faster than once per second.

The preionizer connection was reworked. Leads were added at the back mirror

side of the laser. RpiCpi circuits are similar in all places (50pf x 5.6kOhm).

Since the number of such circuits is now 4 (each of two wires has two ends

and each end is feeded through RpiCpi from the anode) the total preionizing

capacity is now 200 pf.

Got a test run again. Still Cs=6nf and the mixture CO2:air=1:1 was used.

Pressure was 1 bar. At 1 Hz the laser gave ~12-15 mW. When turning onto a

self sustained repetition rate (about 30 Hz) it gives about ten pulses

until dims. The traces on the carbon paper became throughout holes (of course

with focusing).

There was an attempt to increase Cpi to 100 pf. Laser became unstable with

low and unpredictable probability of lasing. There appeared bright spark

discharges inside the laser tube. The sparks run not between the electrodes

but between electrode keeping plates, and one can see that the preionizing

wires play role of ignition electrode as in trigatron.

The Cpi capacitors were returned to 50 pf and the attempt was made to

increase storage capacity. One more 2nf Murata was added. The pulse energy

increased but the bearable repetition rate dropped. As the result the

average power decreased significantly (to ~eight milliwatts).

Interesting notice: when focusing to a carbon paper the plume (visible

spot where the beam hits the target) is not "electric-blue" as for powerfull

TEA lasers, but "yellowish-white" as for low pressure longitudinal CO2

lasers or for solid state free running ones. It probably means that the

resistance of the carborundum electrodes makes the pulse to became long,

possibly to several microseconds.

The main conclusion one can make is that most possibly the deal was

in diffraction losses. In TEA lasers with metal electrodes the last form

a waveguide that keeps wave losses at reasonable level and small spacing

between the electrodes becomes tolerable. The other situation is here:

the carborundum is coarse and highly absorbing. Why "most possibly" not "surely"? Because with higher spacings a higher energy deposition is

possible. There exists a possibility that increasement of energy deposition

with keeping the capacity at constant level (i.e. with smoother discharge)

might have played a role.

Still incomprehensible the nature of lasing stopping at higher repetition

rates. With metal electrodes my TEA's never had demonstrated such a problem,

at least up to 30 Hz.

TEST 4

Further increasement of the spacing between the electrodes. The gas-discharge unit was reassembled. The props between electrode keeping

plates were replaced by ones with 12 mm height. It gives interelectrode

spacing of 5 mm. The placement of preionizer wires relatively to the cathode

was kept intact. Correspondently the distance to the anode cutoff (by vertical

coordinate) has grown to 3.5 mm.

Tests of the unit at the open air with storage capacity equal to 4 nf has

shown nice uniform discharge. It seems miraculous to observe a uniform glow

of such a size in the air. Especially after such efforts directed to the

volumetic discharge ignition.

For the comparison here is a photo of the discharge with preionizer having

been disconnected. The difference is prominent, isnt it? By the way at smaller

spacings the difference is less significant.

The gap in the SG was set to 10 mm and with Cs=6nf the laser got a run on

CO2:air=2:1 mixture at athmospheric pressure. Yielded about 6 mW at ~1Hz.

Still shuts with repetition rate rising. In addition at the ends of the laser

cell there appeared white sparks (jumping from plate to plate via preionizer

wires).

Cs was increased more: to 10 nf (5 of Muratas). The power at low repetition

rate grew to 15 mW. And at last the laser became operational at free running

repetition rate (~10 Hz). It yields ~12 mW. I.e. relatively to the low rate

mode the pulse energy dropped more than 10 times. But it still lases.

However the white arcs at the ends of the cell become so strong that it

may cause troubles with the integrity of the laser.

One more experiment was made: the storage bank was connected to the laser

tube not by a wide metal foil strip as usual, but by a strip having 2 cm width

and 20 cm length (imitation of "feed-by-wire" mode). It still lased but

the power dropped by 4 times (from 12mW to 3 mW).

Conclusion: further increasement of the space between the laser electrodes

from 4 mm to 5 mm wasn't helpfull. With increasement of operation voltage the

preionizer began to work worse (to initiate sparks). So one needs to change the

place for the wires or to reduce the feeding capacity (which is undesirable)

or completely change the preionizer type. In addition there appear round path

breakdowns around the laser gap (not between the carborundum bricks but

between feeding wirings via the preionizer). And after it have sparked several

times there appear charcoal coating on the dielectric (on electrode keeping

plates or props). Such a coating fixes the birthplace of sparks and further

on laser becomes inoperational even at lowe voltages. I.e. when the voltage

is low enough its hard to ionize the gap between the laser electrodes and

(so the output is low) and when the voltage is high enough the gas discharge

unit fails and needs to be repaired. Seems that for the given size of the

carborundum bricks the voltage needed for normal operation (~30 kV) appears

to be too high.

TEST 5 (backstep) (25.10.2014)

Since the increasement of the spacing between the laser electrodes to 5 mm

has not brought any positive, the laser was reassembled back to the previous

configuration (with the inter-electrode spacing of 4 mm).

Then an attempt was made to increase the storage capacity with gradual

decreasement of voltage (only if needed, when too many sparks appear). Step by

step all seven Muratas were installed into the laser frame (14 nf total).

Strangely but there was no need to decrease voltage strongly. The optimal gap

in the main spark gap is near 7.5 mm.

Obviously the discharge is less stable than with 3 muratas for the same

conditions, but way more stable than with 3 muratas and 5 mm spacing between

the laser electrodes.

Lasing tests gave the next results (for not to type it everywhere i'll say

that the pressure was 1 bar/1000mbar/765torr in all tests here below. The

mixture was also without any additives such as xylene or any.)

- on CO2:air=1:1 mixture

The yield was 10 mW at 6 Hz. The power drop from the first pulses in

the sequence to the further ones is evident by the naked eye. The discharge

does also behave correspondently: the share of the violet glow reduces and

the share of the streamers grows. One may propose that it is due to the

electronegative ions accumulation.

- on CO2:combustor=1:1 mixture

Laser gave 42 mW at 6 Hz. Visually there's no drop of power from the

first pulses in the sequence to the subsequent ones. May be by a factor

of two or even less. (For ones who haven't read my other files, i should

remind that the "combustor" is the common air, where the oxygen was

burned out by combustion of a carbohydride fuel. In this particular case

it was done by burning ethanol - sometimes the type of fuel makes some

difference for the discharge form.)

- on CO2:N2=1:1 mixture

Laser gave 96 mW at 6 Hz. In comparison with "combustor" here's even

less drop of power from the first pulses in the sequence to the subsequent

ones. The plume of the laser spot has got a typical "electric" bluish

color. The nitrogen was of the technical grade from a high pressure bottle.

(Yes, I finally got one too. Could not resist to the temptation to find

out how much a nitrogen laser will yield when feeded by pure nitrogen.

However it is a different story.)

THE CONCLUSION: for particularly that carborundum bricks the spacing of 4 mm

between them is fairly optimal. The simplest build of laser, having wire type

preionizer appears to be operational with air:CO2 mixtures at full athmospheric

pressure. When feeded with comparatively pure gases it showed efficiency of 1%

by energy deposition. The reason of that rather low efficiency lies not in the

ohmic losses inside the electrodes. (Moreover now I don't believe that the low

efficiency in Bealieau laser was due to the losses in the resistors. Something

else there. Maybe too slow energy deposition in comparison with the upper laser

level effective lifetime.)

It is clearly seen that it wants higher preionization and maybe higher

energy deposition. For going further more carborundum needed. When I get some

the report will continue.

28.10.2014

The aluminium spherical mirror (the car rearview one, having been washed

out of protective paint) was replaced by a real laser one. The new mirror is

gold plated plano. The front mirror was kept intact. Other conditions are

unchanged too.

On CO2:combustor=1:1 mixture laser gave 9 mW at 6 Hz. Very careful alignment

while laser is running allows to grab as much as 18 mW.

The sense is that with a mirror, having greater reflection, but being plano,

it yields lower energy than with aluminium mirror having focusing properties.

It means that at such a spacing between laser electrodes the plano-plano

resonator already has significant diffraction losses. Significant enough to

lower the output power.

30.10.2014

A try to emulate the nitrogen by cleaning the combustor gas. One car tyre

was filled by the combustor. Then the gas was allowed to flow into another tyre

through a gas-mask filter. Then into that new tyre a technical grade carbon

dioxide from Crossman's cartridge was poured until the volume ratio became 1:1.

With this mixture the laser gave 36 mW (rep rate 6 Hz - the spark gap was

kept untouched).

After that a (fresh) mixture of Co2 with technical grade nitrogen (from a

cylinder) with a ratio of 1:1 was made.

Using this nitrogen mixture the laser gave 60 mW.

It means that cleaning of the combustor gas has gave nothing. The factor

of two difference between yields with nitrogen and with combustor hasnt gone

away. Seems it is due to undercombusted oxygen. It cannot be captured by the

active charcoal.

However the reason of yield decreasement in comparison with previous tests

does bother. The question why anything gets worse is always bothering.

Handlights having been bought a year ago light less brightly even with fresh

batteries. Year to year the cellular phone keeps connection at less and less

distance from the cell. And even when there it seems to be nothing to die...

As in case of this particular laser. Six carborundum bricks, two wires, two

mirrors and a few pieces of plastic. What can occure to that?

Its back mirror was removed, slightly and carefully polished with a paste

for cellular phones restauration. The front mirror was simply cleaned up.

Both mirrors were then placed back and aligned. The laser once again was

allowed to run on a CO2:N2=1:1 mixture. It gave 78 mW but rapidly degraded to

the previous 60 mW.

Front mirror was replaced by more reflective (and less badly used) one.

R=95%. Yield was 18 mW. The front mirror was again replaced. But this case

by less reflective (and more badly used) one. With R=50% yield was...

yield was... Well... At first it was very high. The light spot on the graphite

surface of the calorimeter was large and bright enough to make thoughts of

about 100 mJ or even more. But then the laser got died. It happened too fast to

get enough time to make measurements, so no figures, sorry for that.

Disassembling and defectation has shown some cleavages on two (of six)

carborundum bricks. Possibly the chips of SiC have shortened the preionizer

wires. Probably they could be shaken out without disassemblage of the laser.

31.10.2014

Laser was assembled back (without any modifications or repairings) and

started on nitrogenic mixture: CO2:N2=1:1. The output coupler was still 50%.

It lases. So the pieces of the carborundum definitely could be shakened out

and it was possible to continue the use of the laser without the ceremony of

disassemblage. The output, however, was only 30 mW. And no light on the

graphite at all. After those promising preliminary results it was a bit

disappointing.

To the tyre containing the nitrogen with carbon dioxide mixture a pair

of xylene drops were added. The drops were really small - may be of a 1.5

cubic millimeters. Then the tyre was shakened thoroughly to ensure even

distribution of the xylene vapours. The run on this mixture gave 78 mW.

The first 5..10 pulses show bright light on the graphite. Then it dims and

after ~3-5 seconds (18-30 pulses) there is no signs of light at all. Up to

that moment the calorimeter reading reachs about a half of their static value,

so I still cannot say anything definite about the energy of the first pulses.

So in previous experiments that were only my thoughts that the mixture was

free of xylene. In the reality the rubber tyre smelled with xylene remaining

from the previous tests. And with adding the fresh gas the amount of xylene

in the mixture decreased gradually. At first it came closer to the optimum

and the power of the laser raised. Further on it decreased away from the

optimum and the power began to drop and the laser started to spark. The last

fact actually had caused the cleavage of the electrodes.

The next test was an attempt to forsage the combustor:CO2 mixture by

adding some xylene too. There was no success though. The optimal concentration

of the xylene is rather low and in this case the xylene burns out fast in the

remains of oxygen. If we add too much xylene it burns out not so fast but it

begins to drop the output power by itself. As it was written in most articles: "the discharge became more uniform but no increasement of output power was

observed". That phrase just means that they didnt hit the optimum

concentration.

02.11.2014

Laser had worked for some time and died after that. It did about 1..2*10^3

of pulses with gradual dimming to complete darkness. Even for the mixture of

CO2 with technical grade nitrogen. Disassemblage and visual inspection have

found out nothing. It looks like everything is allright but it does not lase.

Moreover it doesnt even spark. At least it sparks not more than it did when

lasing was OK.

05.11.2014

A new small variant of laser was made. It has electrode length of exactly

one brick (10 cm). The preionization was made by Dumanchin-Farcy scheme:

HV pulse _/\_ O------------+-------------------------------------+

! ! Cpi

|XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX| --- 50

|XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX| ---

|XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX| !

----------------------------------------------------------- !

^ -+

! 4mm ________/ !

V ___ ___ ___ ___ ___ ___ ___ / ___ !

|XXX| 0 |XXX| 0 |XXX| 0 |XXX| 0 |XXX| 0 |XXX| 0 |XXX| 0 |XXX| !

|XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX| / Rpi

|XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX| \ 100k

! /

! \

! /

! !

+-------------------------------------+

!

---

Dumanchin's preionizer is a plurality of insulated metal wires, placed in

grooves in the cathode. In the original form that were nickel wires inside

quartz tubings having diameter of 1 millimeter. Its clear that DIYer is out

of such a resources. If theres none nickel in quartz, how'bout copper in

teflon?

One of the carborundum bricks was grooved by means of some abrasive disc.

It was done by hand engraving tool, so the grooves aren't very even and

straight. However with some fortune one can put nearly 30 grooves over

the length of the brick. (The work appeared to be dirty and uneasy: dust and

spray flew directly into face. If You ever want to do such a thing be sure to

put on glasses and respirator.)

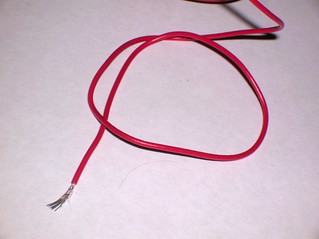

Copper wire in teflon insulation (russian MGTF trademark) was put into

the grooves and connected to the busbar of the opposite polarity. (Kinda

to the anode. Why "kinda" will be clear from the further reading.)

At first the spacing between the laser electrodes was set to 3 mm and

a test run was made. The discharge glow was very bright and uniform and

without any signs of streamers. As they say: "it can't be better!" Then

the spacing was increased to 4 mm with correspondent increasement of feeding

voltage. And here the bad things started. First of all the insulation of

the wire had failed, then the gaps and spacings in the schematic wiring

began to spark, then again the insulation of the wire... The geometry of

the laser auxiliary circuits was revised in order to increase the gaps, and

the attempt was made to reduce the electrical stress on the preionizer.

The direct connection to the opposite polarity was changed by the connection

through a rather small capacitor (50 pf) exactly as it is shown on the figure

above. However it didnt help the wire to survive. After that all available

insulated wires of suitable outer diameter (~1mm) were grabbed and tested.

Some failed earlier than MGTF, others appeared to be stronger. The one most,

strong to the electrical stress, that i have found looks like this:

can not surely determine its trademark by how it looks like. It is

elastic stranded wire, its insulation looks like PVC. And it was found

inside a very old LPT printer connection cable. Thats all i can say.

This wire withstood about three thousands of pulses when the

main spark gap was set to 12 mm (about 31 kV). Since in our laser the

voltage should be lower one may expect that this wire will show certain

lifetime. After the preionizer had been made of this wire the breakdowns

ceased. The volumetic discharge with some streamers was then obtained

for the interelectrode spacing of 4 mm. But for some reason the electrode

with the preionizer wishes to be anode. For the other polarity no glow

discharge appeared. Sparks only.

For the tests of lasing this little testbed was sealed into a cut of

two-inch PVC tubing with the mirror alignment units on the ends. The

mirrors were: the back one - aluminium on glass, spheric R=2 meters,

the output one - ZnSe, dielectric, ro=95%, plano. The distance between

mirrors was 185 mm. The gas mixture: technical grade nitrogen with

carbon dioxide from Crossman's cartridge, 1:1 proportion. Also an addition

of xylene was used in amount of ~5 cubic millimeters per 20 liters of

the gas mixture.

It lased without any difficulties. At the repetition rate of 1 Hz it yields

12..15 mJ per pulse. At higher rep rates it dims rapidly. As it was with the

previous type of laser: the first pulse is powerfull, the second one is weak,

and further on is darkness.

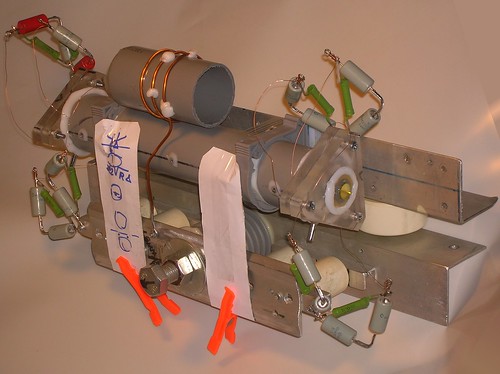

Here is how the laser looks like (dont look at the size of the frame, it is

just universal, and intended for placement of much greater devices. You better

go figure the size of the laser tube itself.)

The storage capacity is 4 nf (it can be seen on the photo, that only 2

Muratas are used), charging voltage is 21 kV (8mm in the main spark gap), and

if the voltage of the glowing discharge is 3 kV/mm, then the charge, having

flown before dimming/contracting of the discharge, will be:

q=4e-9F*(21000V-4mm*3000V/mm)=3.6e-5 Cl

And the energy deposition in gas:

E=qU=3.6e-5 Cl*4mm*3000V/mm=0.43 J

I.e. the efficiency by the energy deposition is 2.8..3.4%.

And the full efficiency (related to the stored energy CU^2/2) is 1.3..1.7%

Even while remembering that we use rather clean gases, the efficiency

value obtained for such a short laser does impress.

In principle hereabove is a (not)great handwaving, because I've taken the

field tension for the stationary glow discharge to be equal to the breakdown

field tension for the air. (Even, not for the nitrogen!) But, say, in [4] they give 30..35 kV/cm for the field tension for the glowing phase in pure CO2.

10.11.2014

An ability of the short (10 cm) laser with Dumanchin's preionizer to operate

with mixtures with air and with combustor was proven. On the air:CO2=1:1 laser

gave ~6 mJ and for the combustor:CO2=1:1 it yielded less than 5 mJ - its hard

to measure due to low power and instabilities, but it gives definitely less

than with air. Its curious that the combustor, being usually better than air,

gives here such a fail. Most possibly it is due to contamination by water

vapours. The laser is short, the gain is small, and in above all that

the quenching by H2O appears.

With both mixtures the the top rep rate, when stable operation is possible,

is even less than with nitrogen: once per 2 sec for air based mixture and

something like once per 3 sec for the combustor based one. Pulse-to-pulse

stability became worse too. Consequent pulses may easily differ in energy

by the power of two. It looks like the laser sits just over the threshold.

In order to check a possibility to build the laser having no vacuum pump,

a test was done to run the laser with filling by washing mode. The laser was

evacuated (to less than 100 torr), then filled with air. Then the exhaust

pipe (at the rear mirror) was opened to the athmosphere and the inlet pipe

(the one at the front mirror side) was fed by the premixed N2:CO2 mixture.

When about 5 liters were flown down, it lased similarly to the case of air

with co2 mixture. After that 5 liters more of the mixture were allowed to

flow through the laser. After that it gave well formed laser spot when

observed by the light on a piece of carbon paper. Further on another 5 liters

of gas were passed through the tube. This time the lasing power was almost

undistinguishable from the one in case of tests with normal filling.

If the volume of the laser tube is VL=L*pi*d^2/4=13*3.14*5^2=255 ml, then

it results that the washing ratio should be k=V0/VL=40..60. If one can provide

such washing ratio when filling by gas blow, the laser will work well.

11.11.2014 GRIDDIE

A new laser was assembled. As it was in case of Dumanchin's one it has

electrode length the same as the length of the brick. Anode was made of one

carborundum brick 100x10x3 mm. Cathode - a grid from a kitchen sieve. The

power supply was made by this scheme:

+---+------+-------------+---------------+------+

! ! ! ! ! Cpi !

! ! 5k6\ ! ! 50 / Rpi

V ! / ! --- \ 100k

--- \ ! --- /

^ --- / XXXXXXX ! !

! !4x570 ! ---+------+

! ! ! ........_______/

+---+ ! XXXXXXX

! ! !

! +-------------+

--- 2 x Murata !

--- doorknob !

! 2000pf x 40 kV !

+--------------------+

The kitchen sieve looks like this:

It was found out that the mesh can be easily removed just by unbeading

its frame. No need to cut anything. To flatten the mesh was also easy, despite

any infernal expectations. The size of the mesh cell is 2 mm. It better be

smaller, but one uses what he has. The spacing between the mesh plane and

the anode is 4 mm.

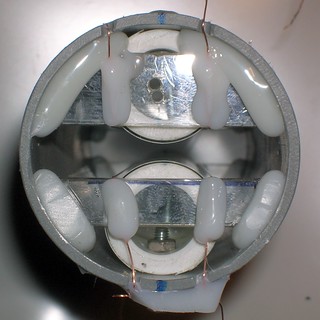

Behind the grid there is a preionizing electrode - a similar carborundum

brick. Size of the mesh is greater than the size of the brick with a reasonable

surplus. Pay attention to the fact that the brick, that is placed behind the

mesh, is not just a preionizer. Naturally all the supply current goes through

it. I.e. this circuit is the one with feeding through the preionizer. Ideally

it should provide preionization not only by the UV, but also by the electrons

having been extracted from the auxiliary discharge into the main discharge

by the electric field.

At the very first test the scheme sparked happily. The sparks went not

between the anode and the mesh, but between two carborundum bricks, through

the cells of the mesh. After a bit rework of the RC circuit of the preionizer

some glow was finally obtained. But... As it was seen from the end of the laser

the glow appeared not between the planar faces of the electrodes, but around

their sharp edges.

The edges of the bricks were rounded. This work can be done by a diamond

cutting disc and a hand engraving tool. What do You think, had the glow

moved to the planar faces? No. It disappeared completely. Only sparks remained.

In the torture process of the spark suppressing many things were done.

Even a guard discharger was added:

+---+------+-------------+---------------+------+

! ! ! ! ! Cpi !

! ! 1k1\ ! ! 50 / Rpi

V ! / ! --- \ 100k

--- \ ! --- /

^ --- / XXXXXXX ! !

! !4x570 ! ---+------+

! ! ! ........_______/

+---+ ! XXXXXXX V

! ! ! ^

! +-------------+-------+

--- 2 x Murata !

--- doorknob !

! 2000pf x 40 kV !

+--------------------+

The guard spark gap was known to help under the similar circumstances

(US.Pat 3940710). BTW it possibly helps by making a preionization of the

preionization spacing. (Yep, the box in the box.) But with this particular

laser it didnt help. The solution was found in making the electrodes thicker.

+---+------+-------------+---------------+------+

! ! ! ! ! Cpi !

! ! 1k1\ ! ! 50 / Rpi

V ! / ! --- \ 100k

--- \ ! --- /

^ --- / XXXXXXX ! !

! !4x570 ! \XXXXX/ ---+------+

! ! ! !

+30kV ! ! ! ........_______/

o--+---+ ! /XXXXX\ !

! ! XXXXXXX V

! ! ! ^

! +-------------+-------+

--- 2 x Murata !

--- doorknob !

GND 30 kV ! 2000pf x 40 kV !

o------+--------------------+

The slash characters near the crosses (meaning carborundum) are the silly

try to designate that the carborundum bricks have rounded edges. In addition

for the things to be more clear it was needed to show the power supply

connection points. Usually it is clear even to a fish, that the power supply

should be connected to the storage capacitor, but here the polarity of

the connection is important.

Now the electrodes (the main one and the undermesh one) are both glued

of two bricks being placed one onto another. The thickness of the carborundum

increased thus to 7 mm. The spark is still present, but at least it is

accompanied by the glow. The glow is visible by naked eye and finally

takes place between planar faces of the electrodes.

However the test of lasing have shown that the device is inoperational.

I.e. the intensity of the glowing discharge is too weak.

At the last despair try the scheme was "turned upside down":

GND 30 kv

o------+----------+-------------+---------+------+

! ! ! ! Cpi !

! 1k1\ ! ! 200 / Rpi

2 x Murata! / ! --- \ 100k

doorknob --- \ ! --- /

2000pf --- / XXXXXXX ! !

40 kV ! ! \XXXXX/ +------+

! ! !

! ! ____....... !

o------+---+ ! / /XXXXX\ !

+30 kV ! ! ! ! XXXXXXX !

! ! ! ! ! !

! V ! ! +---------+

4x570 --- ! !

--- ^ ! !

! ! ! !

+---+------+---- +

The mesh became anode, the cathode became carborundum brick and the

undermesh electrode became banal preionizing electrode. The full supply

current does not flow through it after all.

The discharge test have shown a "sparky rain", and barely seen glow

at the background. As always in such cases it is not clear beforehand whether

it will lase or the sparks will interfere with lasing.

The laser was started on N2:CO2=1:1 mixture. The resonator was the same as

for previous one (back - Al on glass, sphere, measured R>96%; front - plano,

ZnSe, R=95%). At rep rate of 1 Hz it gave 8..10 mJ. What is more curious it

does not dim with rep rate rising. At ~10Hz it gives ~18 mW, that means 1.8 mJ

per pulse.

However with the combustor based mixture it behaves differently. Not only

it ceases with rep rate rising, it shuts also with time passed - even at the

rep rate less than 1 Hz it gives 5..10 pulses until fading. After that

even the filling by the pure N2:CO2 mixture does not bring it to consciousness.

Only after a long pause (more than 1 hour), and after having been filled by

a fresh pure mixture it begins to lase. I.e. it appears to have a property

to be capable to be poisoned by bad gases.

CONCLUSIONS:

- with good gases the grid-based laser is better than the Dumanchin's one.

it gives the same power but lives at higher repetition rates. With bad

gases the Dumanchin's laser is better.

- for the normal laser operation it needs the sum thickness of the

carborundum electrodes to be twice greater than the spacing between the

electrodes. That's particularly why there was the fail in increasement of

the spacing to 5 mm and above.

- once again it was proved that nothing certain could be said by visual

observations of the discharge. In some cases it lases with sparks in

the laser channel, in other cases it refuses to lase even with a fine

glow.

12.11.2014

Here are the photoes of the laser internals. One can see the mesh, the

carborundum brick behind the mesh, and the fact that the bricks are put

one onto another in order to increase the total thickness of the carborundum.

The griddie laser was run on a mixture with air. It lased but weakly.

The power was unmeasurable by my calorimeter. The light spot on carbon paper,

produced by its focused beam was little - literally having the size of one

pixel. And the pixel is weak, and it does not appear any time.

The tests were made with mixtures of CO2 with air in proportions from 2:1

to 1:2.

| CO2 |

: |

AIR |

|

QUALITIVE CHARACTERISTIC |

2 |

: |

1 |

- |

weak pixel |

1 |

: |

1 |

- |

bright, but still pixel, not strip or macroscopic spot |

2 |

: |

3 |

- |

weak pixel again |

1 |

: |

2 |

- |

no lasing at all |

In any of the tests the lasing was unstable. And it does not seem that

the laser wants low repetition rate, i.e. certain delay between pulses.

It just hard to say whether in this particular pulse will be any lasing

or not. At the rep rate of 1 Hz the laser spot appears with a probability

~10%. And at rep rate of 0.1 Hz it does still appear with a probability

of ~10%. Moreover the first pulses in the sequences tend to be without lasing.

However in the contrast to the combustor based mixture, the air based ones

do not poison laser. I.e. after a certain pause and with fresh batch of gas

it was possible to see lasing again and again.

Generally i believe

(i cannot prove it seriously, so it remains only to believe) that in lasers with the unlimited speed of energy deposition (ones based on metal electrodes, low inductance capacitors, having low inductance wiring, fast spark gap and correctly choosen peaker) the highest gain takes place on the mixture proportions of 1:1 It seems that the energy here is at top too. In lasers with slow energy deposition (Bealieau type and etc.) it can happen that the optimum will go to the higher nitrogen proportions, since the vibrational levels live in it sufficiently longer

Concerning the mixtures with technical grade nitrogen, it need be said,

that this design of laser appeared to be very sensitive to the gas quality.

With the mixture having been stored in (rubber) tyre overnight the output

drops three times in comparison with the fresh mixture.

In order to increase the preionization effectiveness a try was made to

introduce a delay between the preionizing and the main pulse. Due to laziness

the most simple way to do this was selected. (See US Pat. Appl. 10/612848).

The anode was simply connected with the cathode by a dumb shunt capacitor,

and into the feeding circuit a delay element is inserted. The authors of

the mentioned application used an inductor, and here i placed a spark gap)

GND 30 kv

o------+----------+---------------+---------+------+

! ! ! ! Cpi !

! 1k1\ +---+ V SGD ! 200 / Rpi

2 x Murata! / ! ! ^ --- \ 100k

doorknob --- \ ! +-------+ --- /

2000pf --- / --- XXXXXXX ! !

40 kV ! ! --- CD \XXXXX/ +------+

! ! ! 470pf !

! ! ! ____....... !

o------+---+ ! ! / /XXXXX\ !

+30 kV ! ! ! ! ! XXXXXXX !

! ! ! +---+ ! !

! V ! ! +---------+

4x570 --- ! !

--- ^ ! !

! ! ! !

+---+------+-------+

It run with N2:CO2=1:1 with the previous resonator.

It lases but worse than without CD and SGD. Maybe too much is lost on the

spark gap.

A try to replace it with an inductor (LD on the scheme):

GND 30 kv

o------+----------+-------+-------+---------+------+

! ! V ! ! !

! ! ^ SGD ) ! !

! ! ! ) ! Cpi !

! 1k1\ +---+ ) LD ! 200 / Rpi

2 x Murata! / ! ! ! --- \ 100k

doorknob --- \ ! +-------+ --- /

2000pf --- / --- XXXXXXX ! !

40 kV ! ! --- CD \XXXXX/ +------+

! ! ! 470pf !

! ! ! ____....... !

o------+---+ ! ! / /XXXXX\ !

+30 kV ! ! ! ! ! XXXXXXX !

! ! ! +---+ ! !

! V ! ! +---------+

4x570 --- ! !

--- ^ ! !

! ! ! !

+---+------+-------+

When LD is formed by a copper wire, 1 mm in diameter and 5 cm long, and

when this wire is bend nearly to half of a ring the things seem to be quite

close to the optimum and the laser yields the same energy as it did without

all this stuff (SGD, CD and LD). It gives less with larger and lower values

of the LD. It is Curious that when LD is formed by 3-turns coil, wound on

a tubing having 50 mm diameter, the SGD begins to spark. Need to note that

SGD naturally had form of a spacing between the laser tube lead and the

laser frame base, so it could not easily be removed from the scheme completely.

With such a coil (3 turns 50 mm diameter) laser gives energy intermediate

between the optimal one and one in case of only SGD usage.

Again I should note that I'm not scientist - I'm a DIYer. With my instruments and resources the difference by a factor of two is "insufficient" one, it should better be treated as subjective rather than objective difference. Only the difference by an order of magnitude does really mean something.

Hence if in addition one succeed in proving that the preionizer of this

scheme is also tolerant to inductance, it will appear to be that this scheme

can really be "fed by wire". However I have no zeal to do it, since the

griddie laser has shown other shortcomings - first of all the evil sensitivity

to the gas quality.

17.11.2014 STANDIE

With the griddie laser it was found out that the carborundum should have

a certain thickness for the good operation (best if the thickness is nearly

equal to the twice of the value of the spacing between the electrodes). Since

that it seemed that a good way for increasement of the inter electrode

spacing is to increase the thickness of the carborundum, and the very way

to do it is to set the bricks in "standing pose." So the bricks were made

to stand on their narrow face:

////////////////// <-perspex platform

XXXXXXXXXXX

XXXXXXXXXXX <------Carborundum brick

^

! 4 mm

V

O XXX O XXX O

XXX XXX \ wire d=0.5mm

XXX XXX \-------------

XXX XXX

XXX XXX <------Carborundum brick

XXX XXX

////////////////// <-perspex platform

<->

2 mm

Two down bricks were installed in standing pose and the upper brick was

put as lying on its holder plate. Between the standing bricks, along them,

some wires were stretched. If the wires are insulated the schematic becomes "longitudinal Dumanchin's scheme". If they are naked it becomes something

intermediate between Dumanchin's and Lamberton's ones.

If there is no insulation, there is nothing to breakdown. So at first

the naked wires were choosen. The wires were connected to the other polarity

by individual capacitors Cpi1...Cpi3

+- -+------+----O _/\_ HV pulse

! \_____________/ ! !

! XXXXXXXXXXX ! !

! XXXXXXXXXXX ! !

--- --- ---

--- Cpi1 Cpi2--- --- Cpi3

! ! !

+--O XXX O XXX O--+ !

XXX ! XXX !

XXX ! XXX !

XXX ! XXX !

XXX ! XXX !

XXX ! XXX !

+------------- !

! ! !

--- +---------------+

-

(Ground)

Or by common capacitor Cpi:

+- -+------+----O _/\_ HV pulse

! \_____________/ ! !

! XXXXXXXXXXX ! !

! XXXXXXXXXXX ! !

--- --- ---

--- Cpi1 Cpi2--- --- Cpi3

! ! !

+--O XXX O XXX O--+ !

XXX ! XXX !

XXX ! XXX !

XXX ! XXX !

XXX ! XXX !

XXX ! XXX !

+------------- !

! ! !

--- +---------------+

-

(Ground)

The leakage resistors (in parallel to the capacitors) arent shown on the scheme

for the sake of clarity. However in reality they were installed.

The assembly was tested in open air. The storage capacitor was 2x2 nF, the

main spark gap was set to 8 mm. Paradox, but the second schematics (all wires

are soldered together and connected by the common capacitor) shows visually

better discharge than the first schematics, where the preionizing wires are fed

by individual capacitors. Even if the condition of Cpi1+Cpi2+Cpi3=Cpi

is observed.

The assembly was then installed into the plastic tube with resonator (the same

as the above and the above of the above) and tested with the N2:CO2=1:1 mixture.

NO LASING. Even with fresh gas. Even at low rep rate. Even at the spacings

up to 12 mm in the main spark gap (up to 31 kV). Neither with individual

capacitors nor with common one.

OK then. The next is the longitudinal Dumanchin's scheme. The naked wires

were replaced by the insulated ones (see note of 05.11.2014)

- --------+----O _/\_ HV pulse

\_____________/ !

XXXXXXXXXXX !

XXXXXXXXXXX !

!

!

!

+--------(O)XXX(O)XXX(O)--------+

! XXX ! XXX !

! XXX ! XXX !

! XXX ! XXX !

! XXX ! XXX !

! XXX ! XXX !

! +------------- !

! ! ! !

! --- +---------------+

! - !

! (Ground) !

+-------------------------------+

(o) - means here the insulated wire.

The discharge became more even. The sparks became more weak. But still no

lasing at all.

A proposition: the resistance of vertically standing bricks is too high.

Or, to be more correct, the field is too weak to cause the avalanche

breakdown in the carborundum. (Since the SiC is semiconductor, it seems to be

capable to enter the state of high conductivity, when the applied electric

field reaches a certain threshold.)

For the checkout only two bricks were left:

- --------+----O _/\_ HV pulse

\_____________/ !

XXXXXXXXXXX !

XXXXXXXXXXX !

!

!

!

+----------(O) (O) (O)----------+

! XXXXX!XXXXX !

! XXXXX!XXXXX !

! /-----!----- !

! +-- ! !

! ! ! !

! ! ! !

! --- +---------------+

! - !

! (Ground) !

+-------------------------------+

And along one of them three insulated wires were put. The spacing between

wire and the other side brick was set to 4 mm. The assembly in the essence is

longitudinal variant of Dumanchin's scheme without any grooves. It is much

simplier to be made than the one described above.

Lasing test has shown the prominent absence of lasing.

Then the spacing between bricks was reduced. It became 4 mm between the

bricks themselves (not between wire and brick as above). The central wire was

removed for not to make obstacles on the long wave light pass.

- --------+----O _/\_ HV pulse

\_____________/ !

XXXXXXXXXXX !

XXXXXXXXXXX !

!

!

!

+----------(O) (O)----------+

! XXXXXXXXXXX !

! XXXXXXXXXXX !

! /----------- !

! +-- !

! ! !

! ! !

! --- !

! - !

! (Ground) !

+-------------------------------+

Such a scheme hadn't refused to lase. With the negative polarity on the

electrode with the preionizer the laser yielded 3.6 mW @ 1 Hz and 24 mW

@ 16 Hz (1.5 mJ for those lazy to use calc.exe). With the positive polarity

on the electrode with the preionizer, it gave 4.2 mW @ 1 Hz and 30 mW @ 16 Hz

(~2 mJ).

Maybe it is not much, but in comparison with all previous carborundum lasers

it shows amazingly low dropdown with the increasement of the rep rate.

By the way, I hope that You are already got used to the ASCII graphics. Up

to this moment the file already contains 17 schemes. In the pixel form I'd

got mad to draw them, and You - to download them.

20.11.2014 SPARKY

↑

OK, we've reached the point to test a "classic" scheme with spark type

preionizer. Possibly most of You were quite impatient to wait for these

results.

The most simple scheme is going to be assembled:

+---+------+----+----+----+----+------+

! ! ! ! ! ! ! !

V --- --- --- ! --- --- Cpi !

--- --- --- ! --- --- !

^ !Cp ! ! XXXXX ! ! !

!SG ! V V V V /

+---+ ^ ^ ^ ^ SGpi \ Rb

! ! ! XXXXX ! ! /

! ! ! ! ! ! \

--- +----+----+----+----+ /

--- Cs ! !

! ! !

+----------------+----------------+

For the sake of the simplicity it is not shown that in parallel to

each preionizing capacitor a 5.6 kOhm resistor is connected. There are

also shown only 4 of the capacitors. In reality there are 8 of them.

As a few previous variants this laser has short electrodes. Their length

is equal to the length of one carborundum brick. The inter-electrode spacing

will be set to 4 mm.

Additionally in the process of the assemblage it was found out that my

caliper was broken. So the sizes in the previous variants of lasers (and

especially the interelectrode spacing) may have been measured incorrectly.

I hope the error was small, but if You want to reproduce one of the lasers,

You should be prepared to +-1 mm variations. Just to stay on the safe side.

The preionizing spark gaps are made of M3 screws and placed in 1 cm from

the electrode(s) and in 2 cm from each other. Totally 8 spark gaps (see the

figure):

20 mm

!<-------->!

- O O O O

^

10mm !

V

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

^

10mm !

V

- O O O O

!<-------->!

20 mm

The gap in the spark gaps is to be set to 2 mm. It should be mentioned that

for correct operation the preionizing spark gaps MUST fire BEFORE the

main laser channel ignites. Therefore the gap in the preionizing spark gaps

should be choosen (much) shorter than the main interelectrode spacing.

The typical mistake of amateur laser-builders is the hope in some "non-self sustained discharge controlled by the external UV radiation". Drop it. When a necessary voltage is already applied to the electrodes the affect of any external radiation will cause nothing but spark. The preionization is called so exactly due to the fact that it must be applied before. Up to the moment of sufficient voltage application to the main laser electrodes the gas between them MUST ALREADY BE CONDUCTIVE. Only in that case You have a chance to obtain glowing phase of the discharge.

24.11.2014

The laser was finalized and tested at the next conditions: Cs=6nf, Cp=4x510pf,

Cpi=100pf, Rb=1 kOhm, and in parallel to each Cpi a leakage resistor rated to

5.6 kOhm was installed. The spacing in the main spark gap was 8 mm.

Without artificial limiting of the repetition rate (it did ~16 Hz) the laser

gave:

| With mixture of |

technical grade nitrogen:CO2=1:1 |

78 mW |

(4.8 mJ) |

| With mixture of |

air:CO2=1:1 |

96 mW |

(6 mJ) |

| With mixture of |

combustor:CO2=1:1 |

84 mW |

(5.2 mJ) |

Dont think that the things are bad with the technical grade nitrogen. Just

the mixture was too old (was mixed abt ~3 days ago). The last two mixtures were

fresh. It is more correct to consider that with all mixtures the laser gave

the same energy in the limits of measurement errors.

With any mixture the laser spot on carbon paper is yellowish white without any signs of blue "electric" color.

An attempt was made to add an inductor into the feeding circuit:

+---+----+ +-----+----+----+----+----+------+

! ! ! ! ! ! ! ! ! !

V --- ) ! --- --- ! --- --- Cpi !

--- ) Lt ! --- --- ! --- --- !

^ !Cp ) ! ! ! XXXXX ! ! !

!SG ! ! ! V V V V /

+---+ +-----+ ^ ^ ^ ^ SGpi \ Rb

! ! ! XXXXX ! ! /

! ! ! ! ! ! \

--- +----+----+----+----+ /

--- Cs ! !

! ! !

+--------------------------+----------------+

Lt - was a ~30 cm long cut of flexible copper wire in vynil insulation.

The section of the wire was about 1 square mm. The laser was then tested with

the air:CO2 mixture. It lased. However the output power was 4 times lower than

in the previous tests. After the usual type of connection had been restored the

power did not return to the previous level.

Disassemblage and defectation have shown that one of the carborundum bricks

was broken (possibly by a spark). I.e. one cannot say that the stray inductance

has directly diminished the output. It just made the sparks to appear more

easily. And the sparks in their turn damaged the electrode.

After the scheme will be repaired I should check the operationability in

the "fed-by-wire" mode again, and also I need measure the output at the low

repetition rate.

PRELIMINARY CONCLUSION:

- THE CLASSIC IS THE CLASSIC. It shows good results. But it is due to

some reasons.

- Very high energy of the preionization (more than 14% of the total in

the storage capacitor) helps. Despite the large distance between the

laser channel and the spark gaps it still works.

- the leakage resistors in parallel to the preionizing capacitors were

intentionally choosen as low as 5.6 k. The idea is to provide the UV

lighting of the laser channel even after the capacitors Cpi have

already charged. Even after that with such a low resistance there

exists a continious arc discharge. It is known that all negative ions

have very low ionization potential and can be decomposed even by the

long wave UV radiation. The continious lighting should provide

negative ions decomposition and releasement of the free electrons at any

stage of the discharge. Judging from the operation of the scheme with

the air based and combustor based mixtures the principle really works.

I.e. the continious UV lighting does compensate the bad action of the

electronegative gases, such as oxygen.

25.11.2014

The broken brick in the laser was replaced with another one. The laser got

a test run. The yield was miniscule. The cause was the replacement brick. It

has a trace of a spark breakdown from previous experiments. Maybe due to this

fact or maybe due to its own properties (such as e.g. low conductivity) but

when this brick is installed the glow is weak and the spark is strong.

Another replacement of bricks was performed.

This time the laser seemed to resurrect: 84 mW at 16 Hz rep rate.

At 1 Hz it gave 9 mJ. I.e. the energy drop with the rep rate increasement

was rather low - less than twice.

In order to test the ability to operate with a "high inductance" power

supply the laser was connected as follows:

+-------> <-----+----+----+----+----+------+

! SG ! ! ! ! ! !

! --- --- ! --- --- Cpi !

--- --- --- ! --- --- !

--- Cs3 ! ! XXXXX ! ! !

! V V V V /

--- ^ ^ ^ ^ SGpi \ Rb

--- Cs2 ! ! XXXXX ! ! /

! ! ! ! ! ! \

--- +----+----+----+----+ /

--- Cs1 ! !

! ! !

+--------------------------+----------------+

The storage bank was formed by three mylar film rolled capacitors of

K73-14 type (0.015mcF x 10 kV) having been connected in series. In parallel

to the main spark gap SG there REALLY was NO PEAKING CAPACITOR. It was not

an error, it was a survival test. Rb=100kOhm. All connections were made by

a flexible wire having ~1square mm section. The spacing in the spark gap

was set to 8 mm.

It's amazing, but the laser was able to operate. It gave 40 mW at 11 Hz

repetition rate. It worked for a few minutes (just enough to measure its

power) and died.

It was found out that in the bricks there appeared a new hole made by a

spark. And instead of the nice glow there are only sparks when trying to

turn on the laser.

THE CONCLUSION:

Generally speaking we've got almost perfect scheme of laser.

- It works at athmospheric pressure with gas mixtures of almost any

purity grade, regardless whether they contain oxygen or not.

- It keeps the energy output with increasing the repetition rate.

- It provides high gain - even the laser with its electrodes as short

as 10 cm was capable to operate with decent efficiency and output.

- It gives long pulse - the dream of many CO2-laser designers. I probably

won't make much error if I say that it has duration of several

microseconds.

The scheme has only single one shortcoming:

- IT IS NOT RELIABLE!

While there is an even glow discharge - all things are OK, but when

a spark appears it means the carborundum is dead. And there's almost

no way to completely avoid the appearance of sparks.

The operation of the scheme was so impressive that a proposition appeared:

what if this scheme is better than the one with holed electrode and the barrier

discharge preionizer. May be all these years we've played fools and the first

fails with the classical scheme were nothing more than experimental mistake.

For the test purposes two aluminium electrodes were made. They have shape of

parallelepiped with all edges having been rounded. 10 mm wide, 100 mm long

and 4 mm in height. The working side of the electrodes was polished.

Those electrodes were installed in place of the carborundum ones and the

laser tube was connected to the low inductance pulse supply (the one with

Murata capacitors). Cs=4nf.

The tests with gas mixtures based on air and on combustor have shown no

miracle. With the metal electrodes the scheme produces sparks only. No glow,

no lasing. No light inside the tunnel. It does not produce the glow even

when having been pumped out to 25 torr. A bit disappointing. But on the

other hand it means that the laser with drilled electrodes and with

barrier discharge preionization was discovered not in vain. In its most

primitive modifications it gives volumetic discharge with air based gas

mixtures at 200..300 torr, and the last variants of this laser are

operational with air:CO2=1:1 at slightly higher pressures than a full

athmosphere.

03.12.2014 LYRICAL RECESSION - CAPACITIVE LASER

↑

When speaking regardless to the laser parameters it is quite easy to

obtain a volumetic discharge in the air at athmospheric pressure. Take two

metal pieces without any sharp edges, wrap them into dielectric foil.

(The dielectric should be thin and electrically strong. Mylar is a good

choice.) Connect these electrodes to a source of high voltage alternating

or pulsed current. Enjoy the result. In some papers they call this kind of

the discharge as "corona on (at) the dielectric surface". As for me, I like

the term "barrier discharge". In sounds more reasonably.

However any attempts to fill the volume of the discharge with laser gas

mixture and to put all this into the resonator will only lead to fail.

The energy deposition is too low here.

To ensure this we can make some simple estimations. Let Egas - is the

field tension corresponding to the discharge glow in the gas (let me remind

that it is equal to the breakdown voltage in the uniform field if we pretend

the accuracy range not better than 10..20%. For the air it will be 30 kV/cm.)

Let Ed - is the electric strength of the dielectric and e - its dielectric

permeability. Apparently the top value of the electric charge q, that can be

passed through a unit of dielectric surface (without breaking it) is equal

to the specific (to the unit of area) capacity multiplied by the charging

voltage (for the obvious reasons the latter cannot exceed Ed*delta):

q = Ed*delta * e0*e/delta = 8.85e-12*e*Ed

Curiously that the thickness of the dielectric delta has gone. And the

laser feeding voltage hasnt been left in the expression too. The limiting

charge per unit of area appears to be related only to the properties of the

dielectric.

From the experience of nitrogen lasers we know, that the mylar foil can

hold as much as 10 kv per each 100 mcm of thickness. I.e. 100 kv/mm or 1e8 V/m.

The reference value of the dielectric permeability of the

polyethyleneterephtalate (this is the true name of the mylar) is e=4. However

my own measurements of the capacity approve only e=2. So:

q = 8.85e-12*2*1e8 = 0.0018 Cl/sq.m = 0.18 mcCl/sq.cm.

The electric power is definitely the electric current having been multiplied

by the voltage drop (on the part of the circuit). The voltage drop on the gas

discharge is a very conservative value. So conservative that some time ago some

gas discharge stabilitrons were produced. I.e. the circuit with the gas

discharge can be approximated with a circuit having a stabilitron with a

reference voltage of Egas*Delta:

o o

! !

! ---

------- ---

======= ! Ust=Egas*Delta

+---L<|---+

======= !

------- +---------+

! !

! ---

o ---

!

o

The electric energy deposited in the gas (on the stabilitron) is:

W=S*q*Ust=S*q*Egas*Delta

Where S - is the area of the electrodes (area of the discharge cross

section) and Delta is the value of spacing between the laser electrodes.

The energy specific to the unit of volume is:

w=W/(S*Delta)=q*Egas ; w=8.85e-12*e*Ed*Egas

As we can see all the technical parameters (area and height of the

discharge) have gone again and we left with the electric parameters of the

dielectric and the gas only.

For q = 0.18 mcCl/sq.cm, and Egas=30 kV/cm (the discharge in the air

between mylar insulated electrodes): w=5.4 mJ/cub.cm=5.4 J/liter.

Most TEA lasers have the threshold of lasing at 50..70 J/liter. And from

the formulas above it can be clearly seen that neither voltage variations

nor dielectric thickness changes can help to improve the situation. Only

other dielectric type can help. Such as barium titanate, that is used in

the ceramic capacitors. But it is the very other story.

Thinking on the obtained formulas gives another curious conclusion.

One should remember that the Ed decreases with the dielectric thickness

increasement. If we have something about 100 kV/mm for the thin mylar foil,

it will drop to somewhere near 30..50 kV/mm when we use the mylar with the

thickness of about 1 cm. It means that the capacitive laser should be kinda

low voltage with thin dielectric rather than high voltage with the thick one.

The said above is true for the case of single charge. And if we can recharge

the capacities N times during the necessary time, the energy deposition will

grow N times. The value of N is understandable: if we want the energy

deposition to be at the level of "good" lasers then N =200J/l / 5J/l =40.

And how long can be is that "necessary time"? The energy must be put in

the gas before the carbon dioxide will loose it. In other words the energy

deposition time must be less than the lifetime of CO2 molecule at the upper

laser level. The lifetime of CO2 having been mixed with air and at athmospheric

pressure is kinda hard to find in literature. The very rough estimations

give something like 1 mcs. I.e. one should be able to recharge the laser

electrodes 40 times during 1 mcs of time. Thus the feeding frequency will be

10 MHz (4 recharges per full period of oscillations). If we orient to the

feeding energy of 1 J it will mean the power of the HV generator of

1 J/1mcs=1 MW. Its a dead end. The results of attempts to create 1 MW

rated HV HF power supply can be seen here

Apparently its unreal to make the capacitive discharge laser based on

the mylar dielectric. However the previous test laser (the sparky) has

shown that things can be not so bad. It was operational when fed by

the capacitors that just cannot discharge faster than in 4 mcs. So the

estimation of the necessary energy deposition time can be corrected to

the better direction.

One way or another, but the capacitive laser was created.

Here is the

scheme of its design.

Its body is the old good plastic sewer pipe, 2 inch in diameter. The laser

electrodes are made of the pieces of another plastic tubing. This one has 20 mm

outer diameter. The conductive part of the electrodes (the plates) is formed

by sticky aluminium tape. And the barrier layer is formed by 120-mcm mylar

foil. The working length of the electrodes is 100 mm. The full length of the

laser (mirror-to-mirror) is 205 mm. The mirrors are just the same as were in

the previous and the pre-previous lasers.

Here is the connection schematics:

+--/\/\/---+

! Cpi ! +-/\/\/\--+

+---||---+ +----||----+ ! !

! ! ! ! ! !

! ! ! +---+-||-+----+

! ! ! ! ! !

+--> <--+-----+------o) (o----+

! SG ! ! ! ! !

! ! ! +---+-||-+----+

! ! ! ! ! !

! ! +----||----+ ! !

--- Cs ) ! Rpi ! +-/\/\/\--+

--- ) +--/\/\/---+ !

! ) Ll !

! ) !

! ! !

! ! !

! ! !

+--------+----------------------------+

The preionizers here are in 2 mm from the mylar surface. Two wires per

electrode. The connection is "cross" type, i.e. the wire, that is near the

electrode of one polarity, is connected to the opposite polarity terminal

(through the RpiCpi circuit though).

Cpi=23 pf, Rpi=100 kOhm

L1 is wound on a cut of 50 mm plastic tubing by an enameled copper wire

having 2 mm in diameter. The best results were obtained when L1=1..2 turns.

Cs was always 4 nf.

The most amazing thing is that it lased. Despite all doubts and fears.

The lasing is very weak and with low probability (one lasing per 10..30

pulses) so i can not measure its energy. But visually (by the brightness of

the plasma spot when focused on a piece of carbon paper) i can estimate it

as 300 or maybe 500 microjoules. Also need to say that it works only with

N2:CO2 mixture. Still no lasing was with air:CO2. But at least it lases.

4.12.2014

Here are a few results of attempts to optimize the preionizing circuit

(the main spark gap SG was set to 10 mm)

| Rpi |

Cpi |

probability of lasing |

| 100k |

23pf |

<10% |

| 5k6 |

23pf |

>10% |

| 5k6 |

34pf |

>80% |

| 5k6 |

68pf |

~50% |

Note that the right column contains neither power nor the energy of lasing.

Its just a probability, i.e. the number of pulses with lasing divided by

the total number of pulses. For the smallest values the probability itself

tends to vary.

The main result is that with Rpi=5.6kOhm Cpi=34pf it lases almost every time.

The output power however can change seriously from pulse to pulse.

With Rpi=5.6kOhm Cpi=34pf the laser got a run on a CO2:air=1:1 mixture. The

lasing probability was about 10%. I.e. similar to the behavior with N2:Co2

mixture with unoptimized preionizer subcircuit.

Yes this is neither my first attempt to make a capacitive laser based on

mylar dielectric, nor the first successful. However previous ones vere

operational only at the reduced pressure, when the gain is higher at the same